Fuzzy prediction and compensation control method of tower top temperature for sintering flue gas desulfurization process

A technology for tower top temperature and fuzzy prediction, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as disturbance, low system stability, excessive fluctuation of disturbance factors, etc., and achieve the effect of suppressing the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

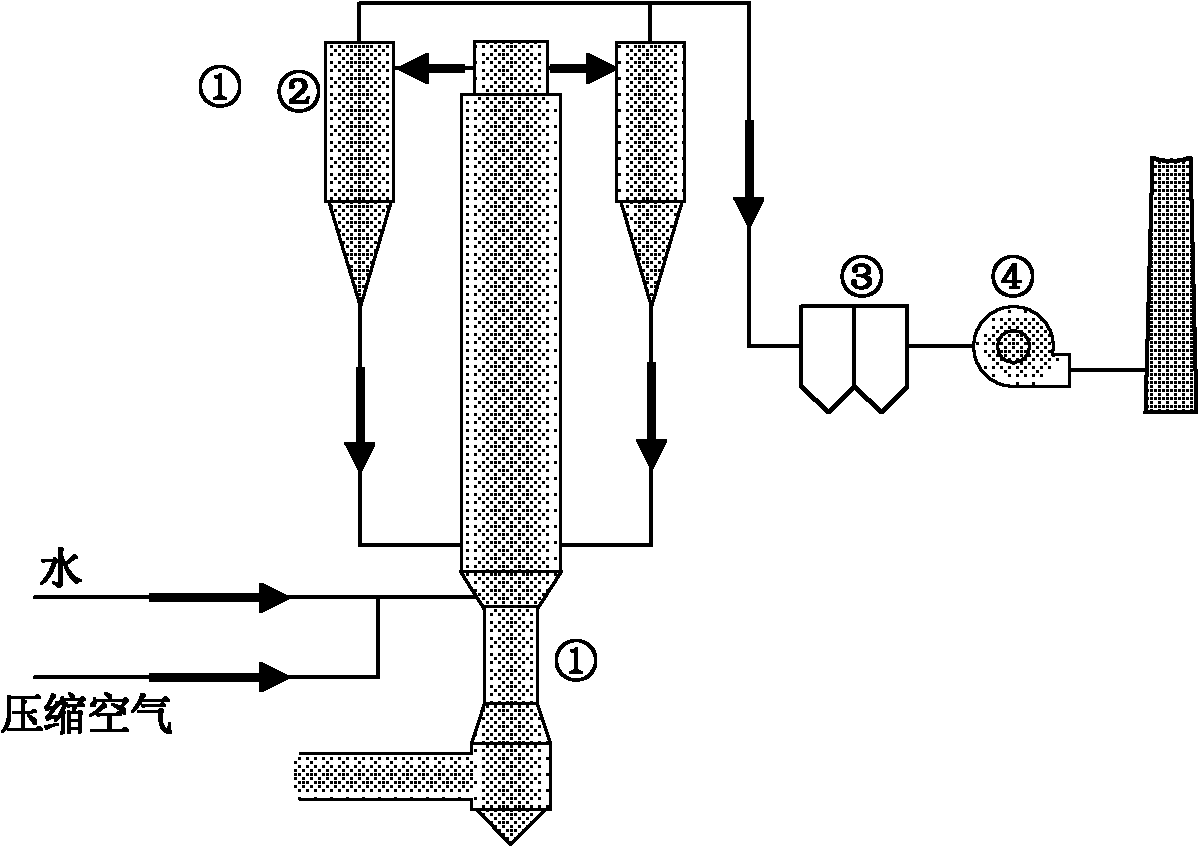

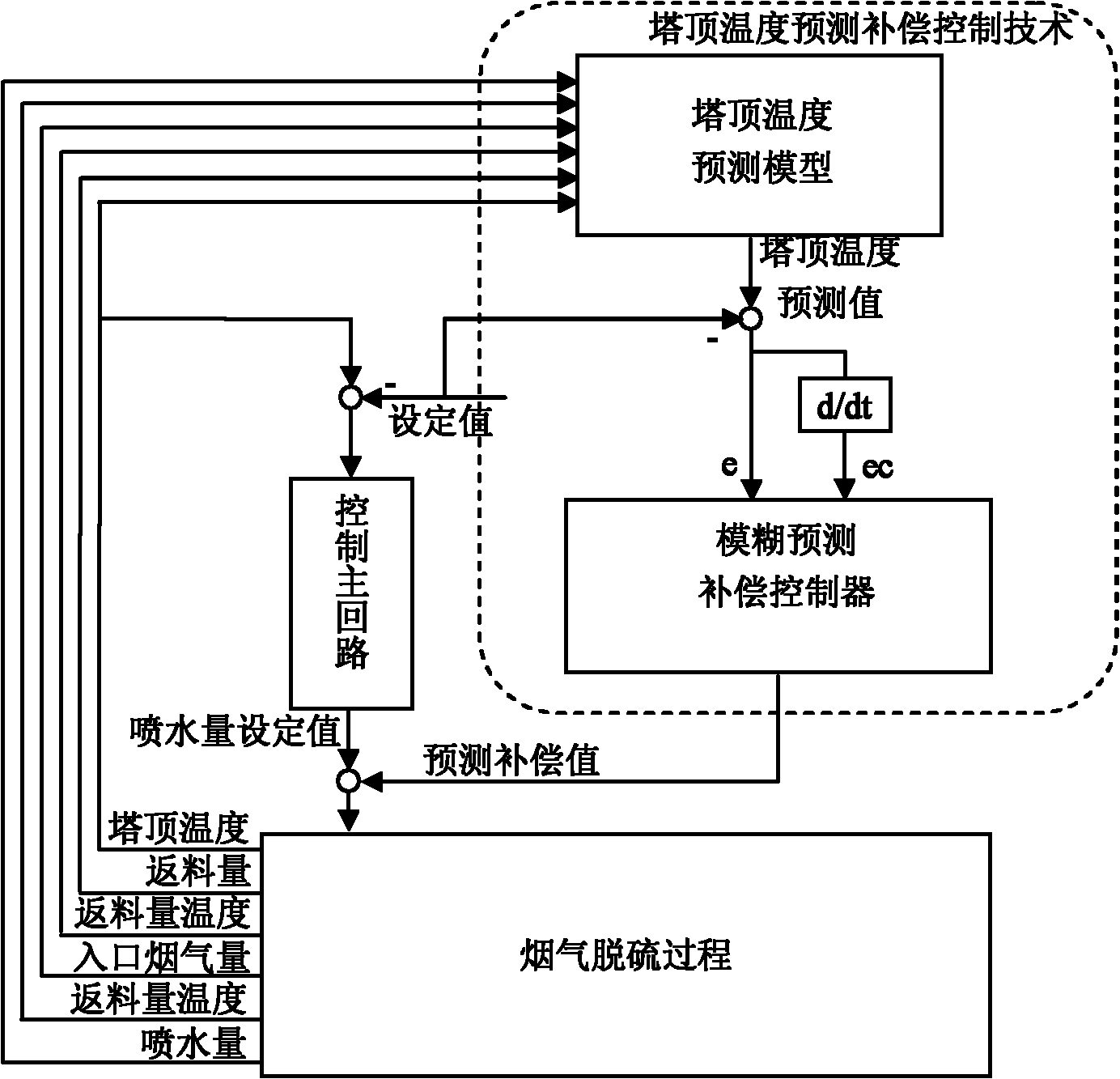

[0043] Such as figure 1 The flow chart of the circulating fluidized bed flue gas desulfurization process is shown. The flue gas enters from the bottom of the desulfurization tower. The desuperheating water and desulfurizer are sprayed from the throat of the desulfurization tower under high-pressure air, and a mist-like area is formed above the throat. , the high-temperature flue gas entering the tower passes through the Venturi at the throat, and then sprays out at a high speed to fully contact and react with the water above and the desulfurizer, and the heat of the flue gas is gradually transferred to the desuperheating water through the water spray cooling method, and the temperature of the flue gas Gradually decrease. At present, in this research field, the detection value of the tower top temperature is generally used as a measure of the temperature environment in the entire tower. After a large number of experiments and field actual project experience, it is concluded that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com