Insulation coordination method for modular multi-level voltage source converter module unit

A voltage source converter, modular multi-level technology, applied in the direction of electrical components, output power conversion devices, etc., to reduce the impact of secondary control and protection systems, improve robustness, and reduce the cost of module units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with example the present invention is described in detail.

[0052] The purpose of the present invention is to provide an insulation method for the module unit of the modular multi-level voltage source converter. When the module unit adopts the insulation coordination scheme, it not only ensures the safety of the equipment and the reliability of the system, but also fully reduces the cost of the module unit.

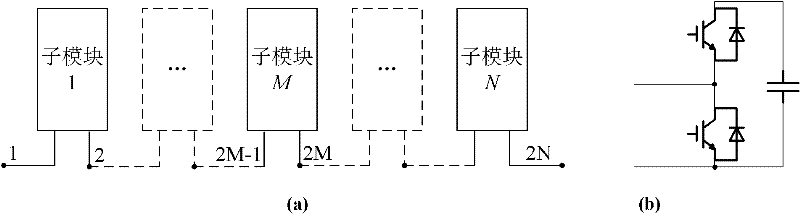

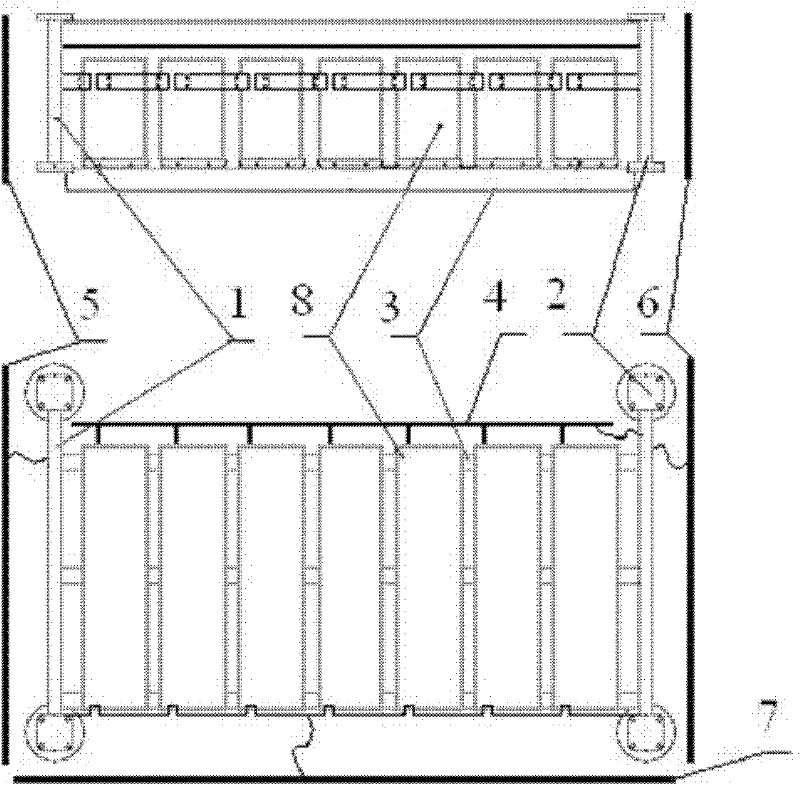

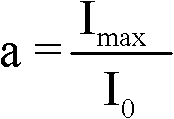

[0053] according to figure 1 The method shown in (a) conducts a systematic analysis of the module unit to determine the maximum steady-state, transient and transient overvoltage levels and the maximum current carrying capacity I that different components may actually withstand max ; In order to reduce the partial discharge of equipment as much as possible, an insulating material with high surface resistivity, high volume resistivity and low water absorption is selected; the conductor cross-sectional area a is generally calculated according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com