Double-layer greenhouse insulation film

A technology of thermal insulation film and greenhouse, which is applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of operation cost and poor efficiency, and achieve the effect of simple structure and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

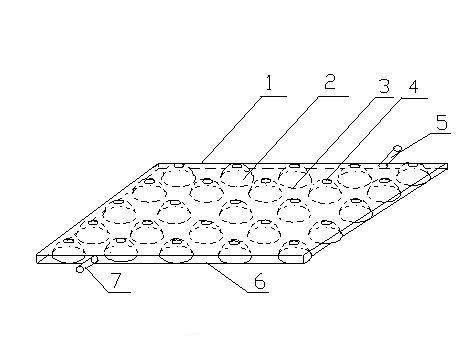

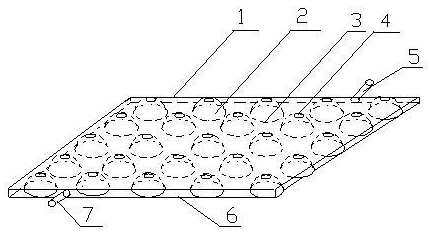

[0009] according to figure 1 , the present invention is made up of flat membrane 1, capsule membrane 6, inlet 7, outlet 5, and capsule membrane 6 is the plastic film that is processed with conical point type capsule 2, and capsule membrane 6 passes through the capsule sticking point 4 of conical point type capsule 2 Bonded with the flat film 1 as a whole, the flat film 1 and the capsule membrane 6 are supported by the capsule sticking point 4 and the capsule bottom 3 of the tapered point type capsule 2 to form a double-layer plastic film; the present invention is provided with an inlet 7 and Outlet 5, filled with water or air through the inlet when in use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com