fast pulping process

A pulping and process technology, applied in the field of rapid pulping technology, can solve problems such as difficulty in meeting the requirements of rapid pulping, inability to produce fresh soy milk, overflow, etc., to shorten the pulping cycle, reduce the risk of overflow and paste pot , Soymilk foam reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

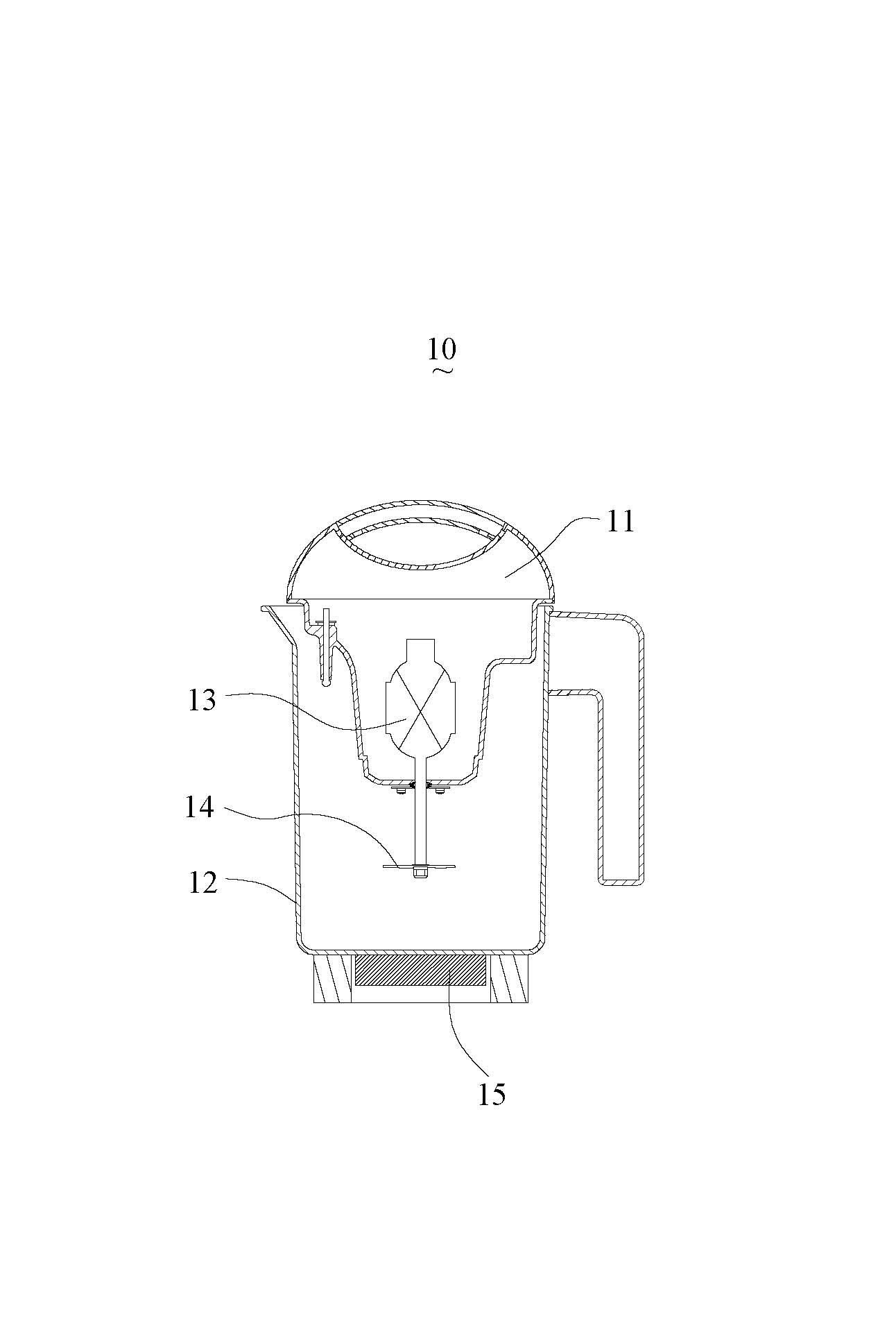

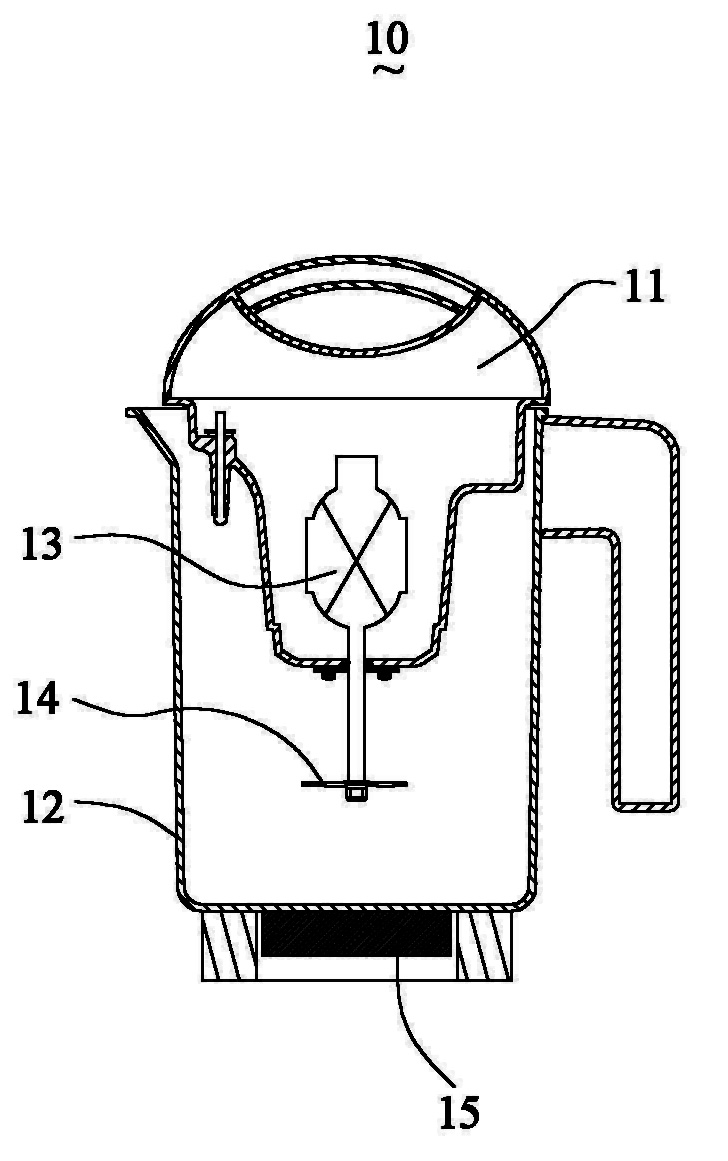

[0033] see figure 1 A schematic diagram of a soymilk machine used in the first preferred embodiment of the rapid pulping process, the soymilk machine includes a machine head 11, a cup body 12, a motor 13, a crushing tool 14, a heating device 15 and a circuit control board (Fig. not shown). The machine head 11 is fastened on the cup body 12 . The motor 13 is installed in the machine head 11 . The crushing cutter 14 extends into the cup body 12 . The motor 13 drives the crushing cutter 14 to rotate and crush the material. The motor 13 and the heating device 15 are electrically connected with the circuit control board.

[0034] The water content of the soybeans used in the rapid pulping process is 11% to 60%. When the water content is lower than 11%, the soybean texture is hard, which is not conducive to the later crushing and the dissolution of soluble substances. The soybean water content is higher than 60%. The heat absorption is large, and the heating and boiling time is...

Embodiment approach 2

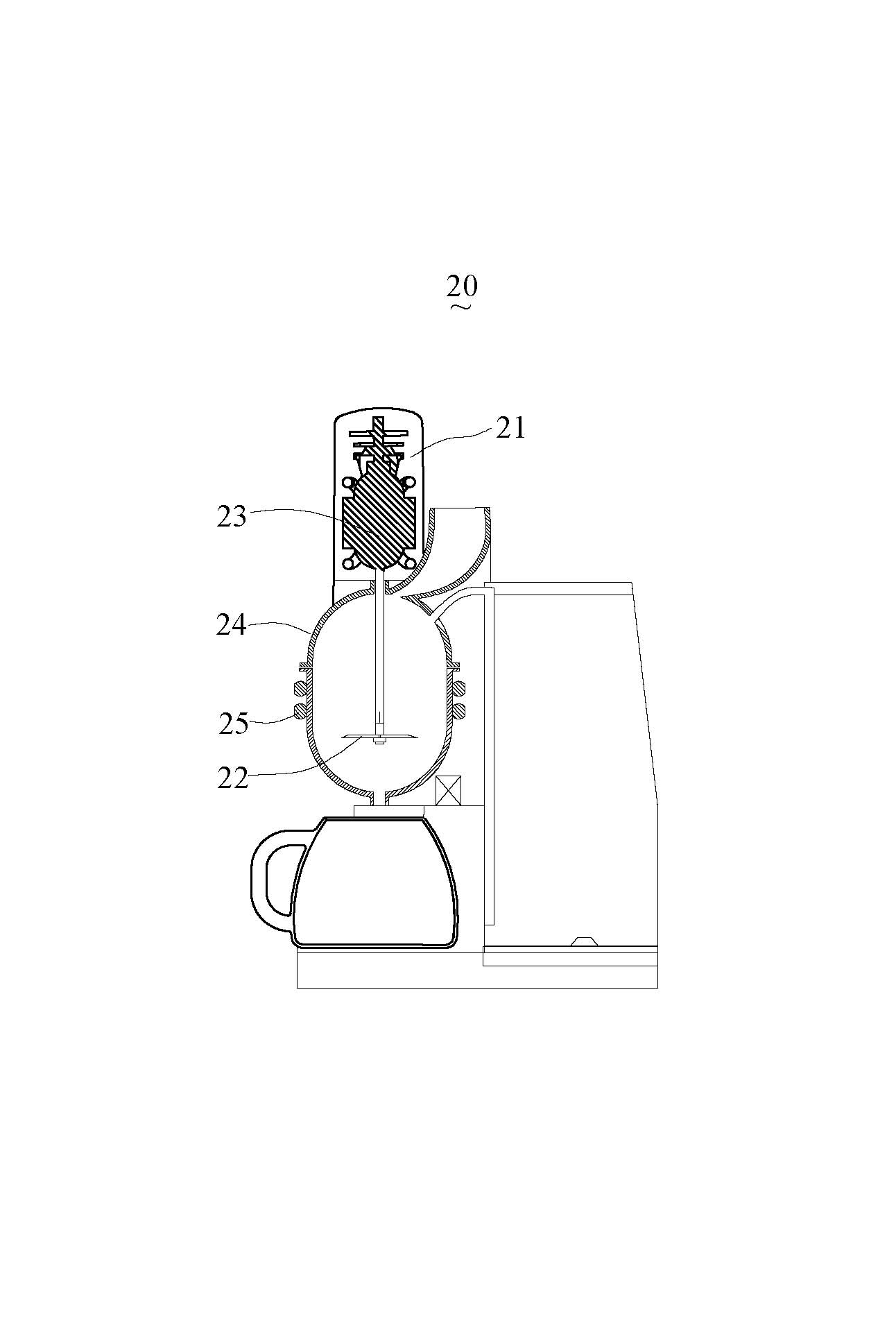

[0042] see figure 2 The schematic diagram of the soymilk machine used in the second preferred embodiment of the rapid pulping process, the soymilk machine 20 includes a machine base 21, a control unit (not shown), a crushing cutter 22, and a motor that drives the crushing cutter 22 to rotate 23. Grinding and maturing device 24 and heating device 25, motor 23 or crushing and maturing device 24 are installed on the machine base 21, motor 23 is electrically connected with the control unit, crushing cutter 22 is located in the crushing and maturing device 24, and the volume of the crushing and maturing device 24 is 100-1000ml.

[0043] Utilize the rapid pulping process of soybean milk machine 10, including:

[0044] (1) The heating device 25 heats the water and soybeans in the pulverizing ripening device 24 to boiling, and maintains the boiling state to deactivate the anti-nutritional factors in the soybeans for the first time;

[0045] (2) The motor 23 drives the crushing cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com