Adjustable Bevel Cutting Control Mechanism for Waterjet Cutting Equipment

A technology of cutting equipment and control mechanism, which is applied in the field of adjustable bevel cutting control mechanism for water cutting equipment, can solve the problems of lack of bevel cutting, high cost of five-axis CNC cutting machine, high processing cost, etc., and achieve Easy to manufacture and install, simple in structure and quick in effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

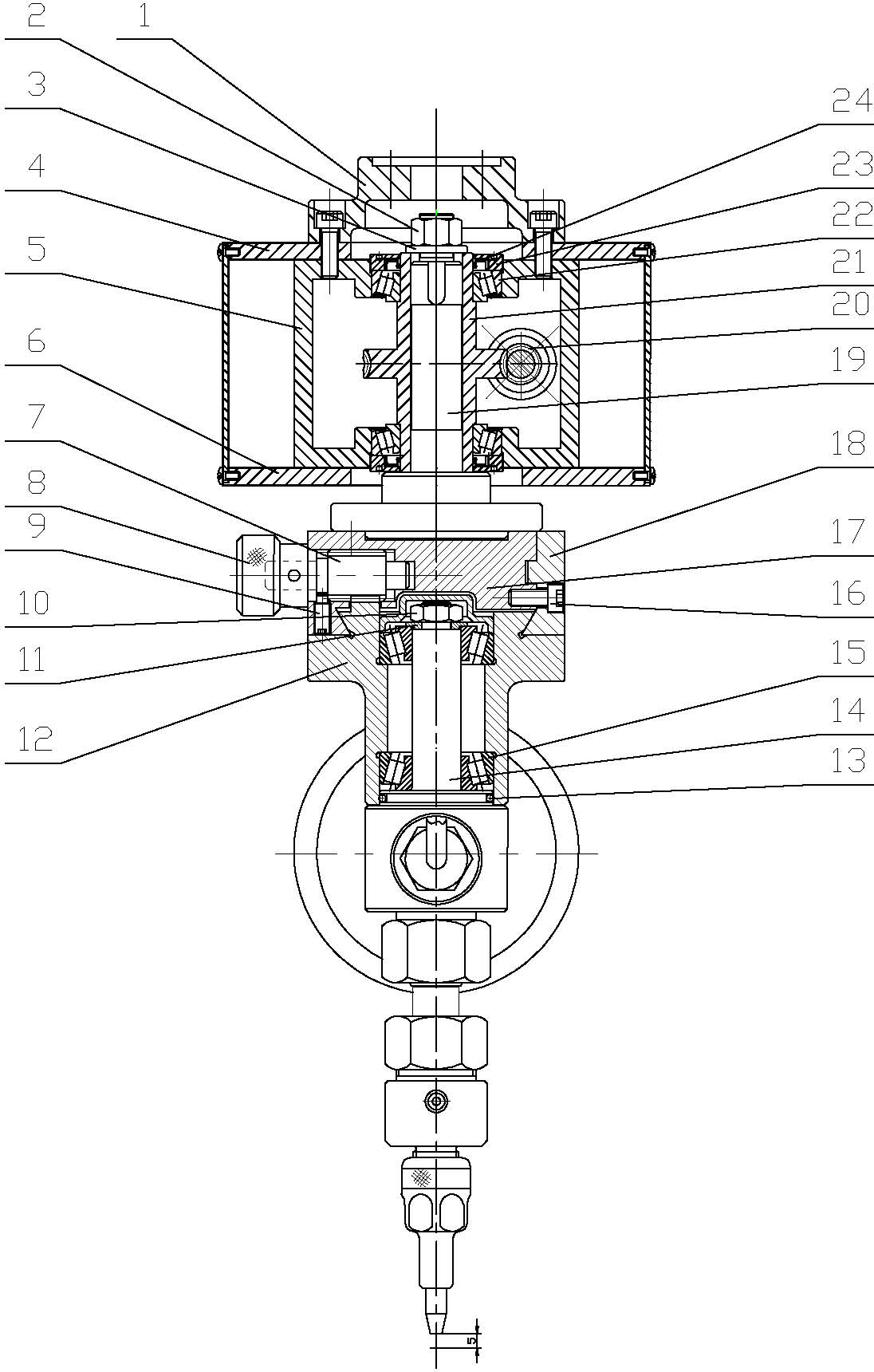

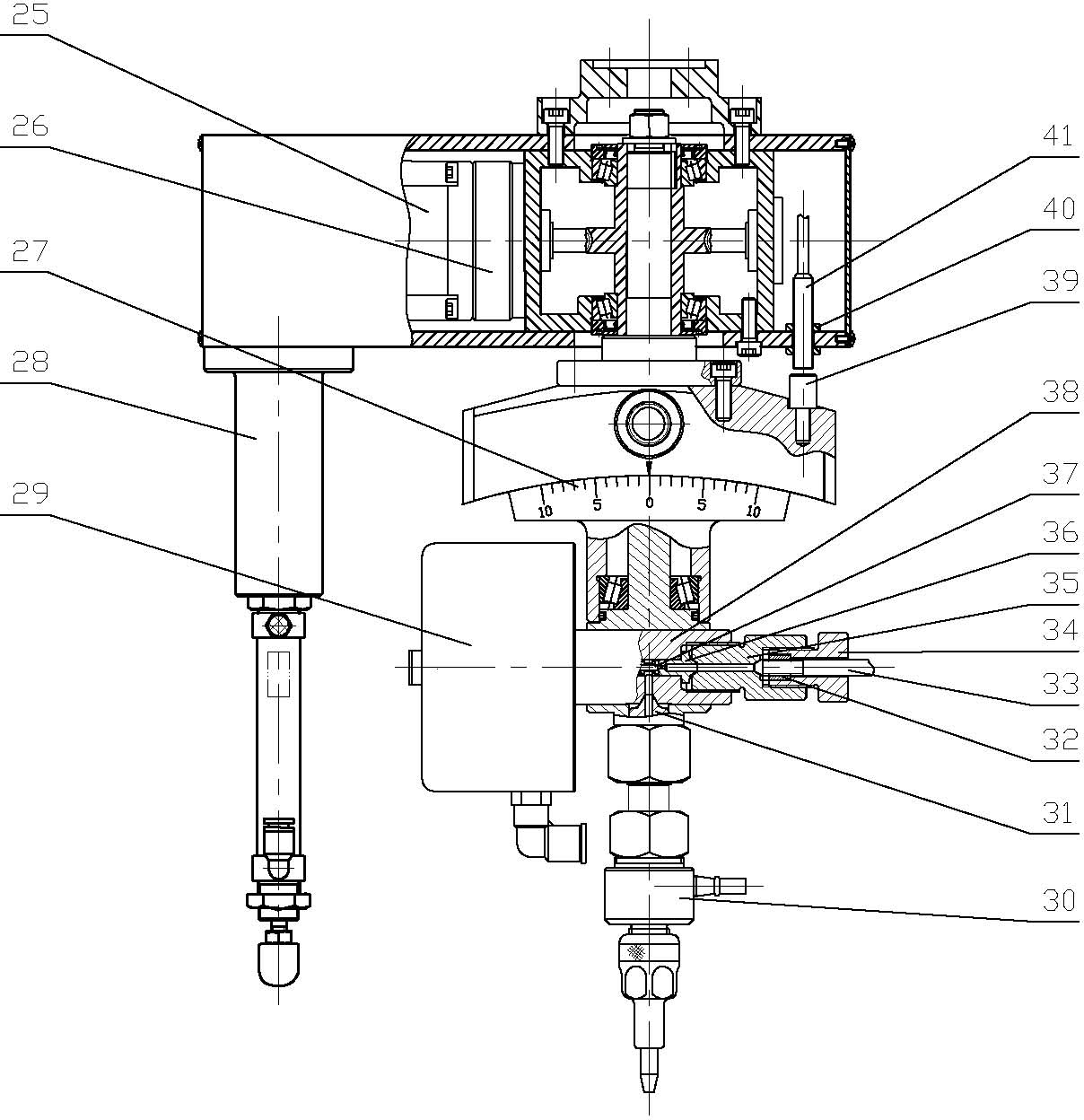

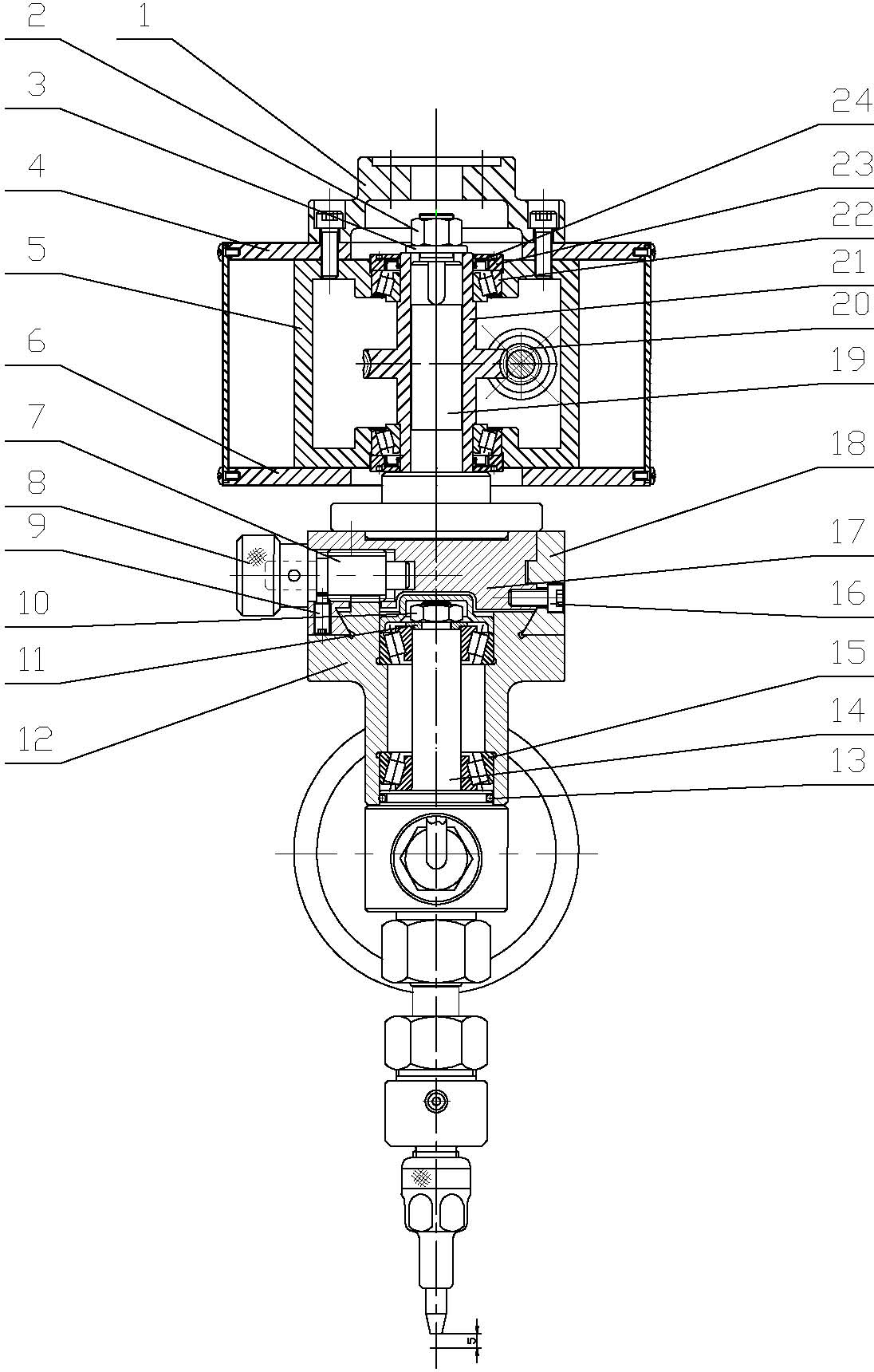

[0019] Such as Figure 1-2 shown.

[0020] An adjustable bevel cutting control mechanism for water cutting equipment, which includes a drive shaft 19, a high-pressure water switch valve 29 and a cutting head 30, and the drive shaft 19 is installed on the box body 5 through drive bearings 22 installed at both ends , the box body 5 is installed in the installation space composed of the upper bottom plate 4 and the lower bottom plate 6, the box body 5 and the upper bottom plate 4 are connected with the connecting flange 1 through the connecting piece (bolt), and the connecting flange 1 connects the control of the present invention The mechanism is connected to the corresponding three-axis drive mechanism. The drive shaft 19 is provided with a worm gear shaft 21 to drive its rotation, the worm gear shaft 21 is engaged with the worm shaft 20, the worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com