Method and device for controlling viscosity loss of oil extraction waste water blended polymer

A technology of oil extraction sewage and viscosity loss, applied in the direction of oxidized water/sewage treatment, etc., can solve the problem of large loss of solution viscosity, and achieve the effect of increasing the oxygen content of the water body, reducing the viscosity loss, and ensuring the polymerization viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

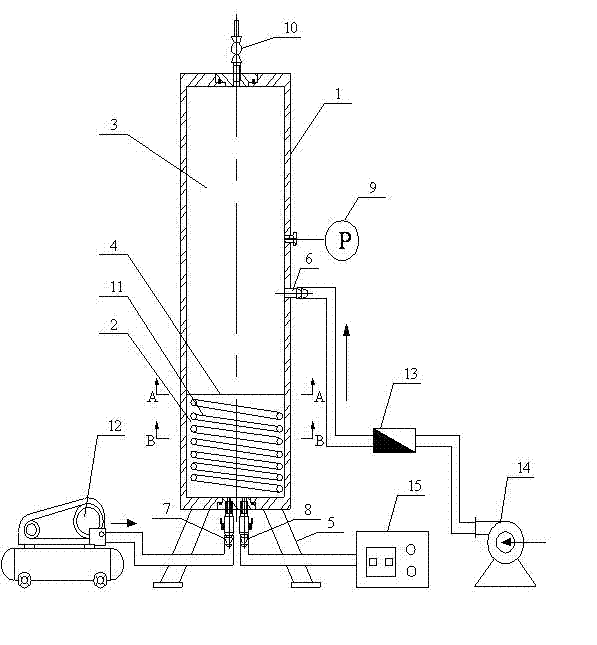

[0041] Adopt the method and the device of the present invention to control the viscosity loss of the mixed polymer solution of oil production sewage to carry out a confidentiality test, use the polymer flooding oil production sewage as raw water, and take the flow rate as 12m 3 / h is pumped into the vertical water collection tank 1, and the first step to the fifth step of the present invention is carried out, and by the first stage test of the technical solution of the present invention, it is 12m to obtain the inflow flow 3 / h, the oxygen exposure pressure is 0.15MPa, and the oxygen exposure time is 7 seconds, the optimal oxygen content of the sewage system is 6.50mg / L. The relationship between oxygen exposure time is:

[0042] Q=0.21×32×3600×10 6 ×k×P / (8.314×298×D O ×t)

[0043] In the formula: Q——influent flow rate, m 3 / h;

[0044] P——Oxygen exposure pressure, MPa;

[0045] t——oxygen exposure time, second;

[0046] D. O ——The best dissolved oxygen content in water,...

Embodiment 2

[0054] Use polymer flooding oil production sewage as raw water, with a flow rate of 25m 3 / h is pumped into the vertical water collection tank 1, and the first step to the fifth step of the present invention is carried out, and by the first stage test of the technical solution of the present invention, it is 25m to obtain the influent flow 3 / h, the oxygen exposure pressure is 0.22MPa, and the oxygen exposure time is 15 seconds, the optimal oxygen content of the sewage system is 6.48mg / L, and the corresponding influent flow rate and oxygen exposure pressure, The relation between oxygen exposure time, its relation also satisfies the description in embodiment 1, wherein in the present embodiment D O =6.48mg / L.

[0055] Using the optimal oxygen content of the sewage system determined in the first stage above as 6.48mg / L as a guide, the water flow rate to the vertical water collection tank is 25m 3 / h pumped into the oil production sewage, the oxygen exposure pressure was 0.22MP...

Embodiment 3

[0059] Use polymer flooding oil production sewage as raw water, with a flow rate of 18m 3 / h is pumped into the vertical water collecting tank 1, and the first step to the fifth step of the present invention is carried out, and by the first stage test of the technical solution of the present invention, it is 18m to obtain the inflow flow 3 / h, oxygen exposure pressure 0.18MPa, and oxygen exposure time 10 seconds, the optimal oxygen content of the sewage system is 6.70 mg / L, and the corresponding influent flow rate and oxygen exposure pressure, The relation between oxygen exposure time, its relation also satisfies the description in embodiment 1, wherein in the present embodiment D O =6.70mg / L.

[0060] Using the optimal oxygen content of the sewage system determined in the first stage above as 6.70mg / L as a guide, the water flow rate to the vertical water collecting tank is 18m 3 / h pumped into the oil production sewage, the oxygen exposure pressure was 0.18MPa, and the oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com