Controller area network (CAN)-bus-based excavator electrical component control system and method

A CAN bus and electrical component technology, applied in the control system field of excavator electrical components, can solve the problems of poor communication reliability, troublesome design, installation and maintenance, and cumbersome wiring harness of the whole machine, so as to improve the stability and reliability, simplify the Harness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in combination with principle diagrams and specific operation examples.

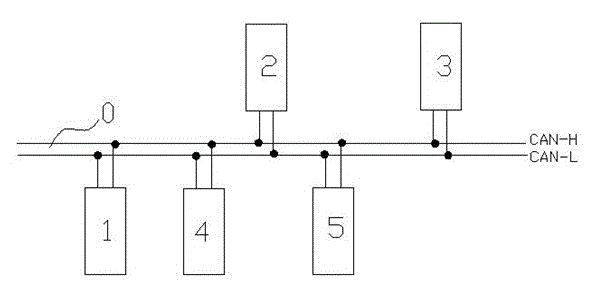

[0031] Such as figure 1 Shown, the present invention is based on the control system of the excavator electric component of CAN bus, specifically comprises main controller 1, keyboard 2, power distribution module controller 3, cooling system controller 4 and engine controller 5, main controller 1, The keyboard 2, the power distribution module controller 3, the cooling system controller 4 and the engine controller 5 are connected to each other through the CAN bus 0. The main controller 1 completes the control work of the whole machine, and the keyboard 2 integrates control buttons such as engine regeneration with a diesel particulate filter, work lights, wiper and fan reversing, and sends switch instructions to the main controller 1 through CAN bus 0, and the power The distribution module controller 3 integrates the relays and fuses of the whole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com