Lower railway truck door locking device

A technology for door locks and railways, which is applied in door devices, railway car body parts, vehicle locks, etc. It can solve the problems of reducing vehicle operation safety, broken lower door hinges, and increasing maintenance costs, so as to solve the problem of self-failure, The effect of prolonging the service life and convenient locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

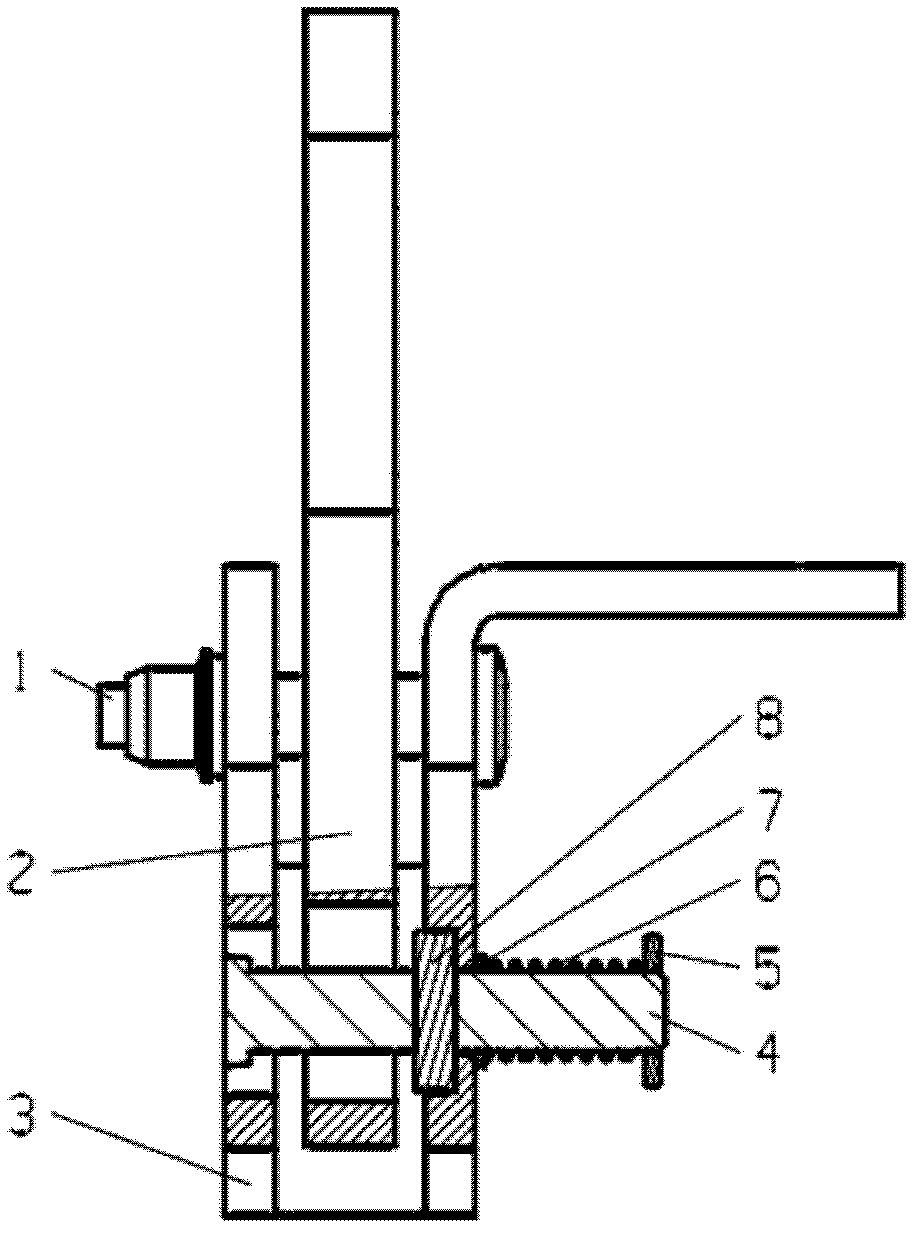

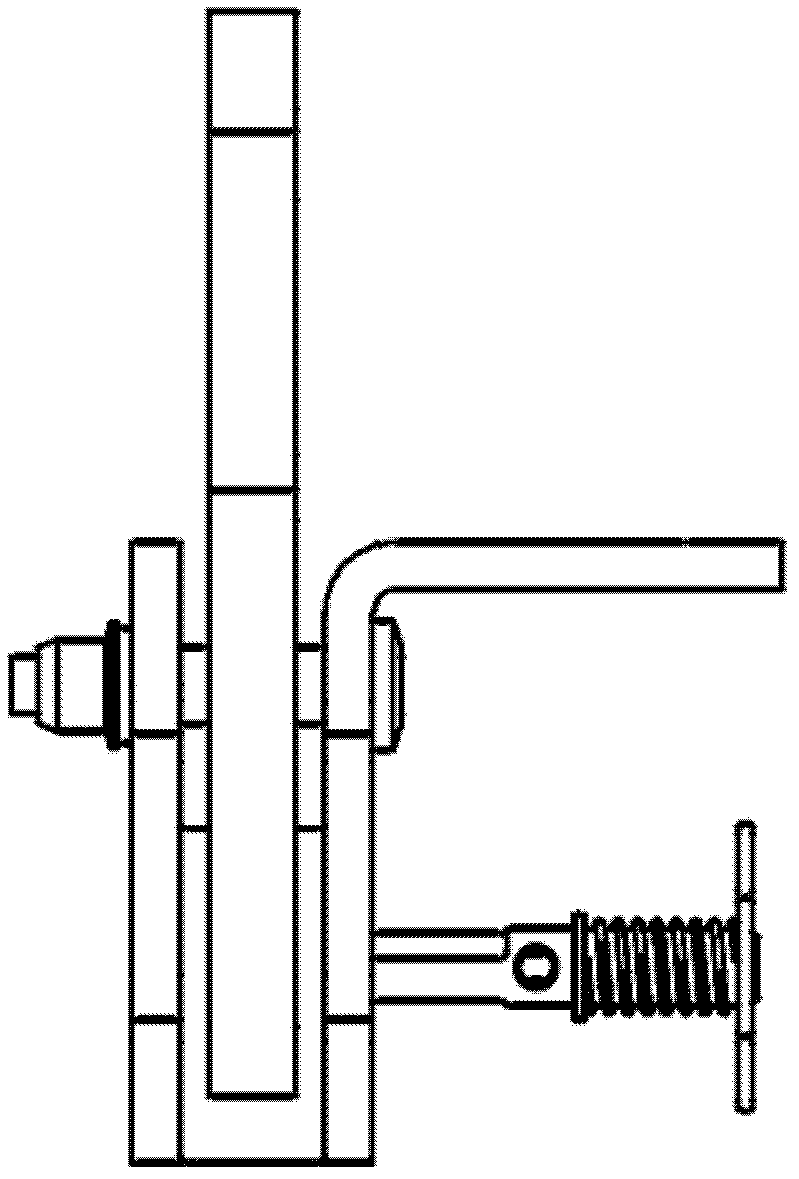

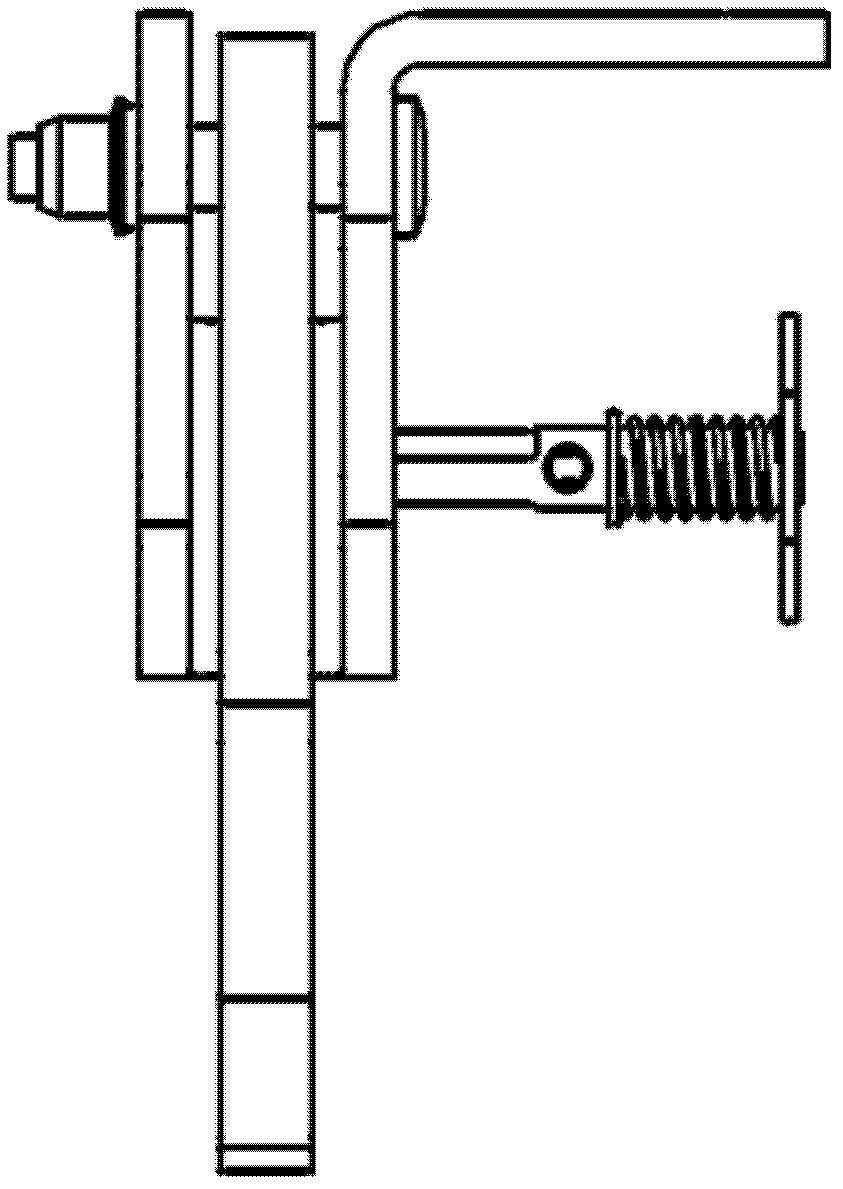

[0018] see Figure 1-Figure 9 , the present invention includes a lock base 3 and a lock iron 2, and the lock iron 2 is installed on the lock base 3 through a blind rivet pin 1 to enhance connection strength and rigidity during operation. Its key technology is that the lock seat 3 is an integral casting, the lower end of the lock seat 3 is a lock iron support surface 3.2, and the two sides of the lock iron support surface 3.2 are provided with webs 3.1, and anti-jump holes 3.3 are respectively opened at the lower ends of the two webs. The anti-jump pin shaft 4 is installed through the anti-jump hole 3.3; the anti-jump hole on one of the webs is an anti-jump through hole, and a strip-shaped The through hole 3.5, the counterbore 3.4 and the elongated counterbore 3.6, the counterbore 3.4 and the elongated counterbore 3.6 are on the same plane, the counterbore 3.4 is circular, and the elongated counterbore 3.6 is rectangular, long The length of the strip-shaped counterbore 3.6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com