A method for testing the force of bolts connecting shield tunnel segments

A technology for shield tunnel segments and connecting bolts, which is applied to the mechanical state test of shield tunnel segment connecting bolts and the field of force testing of shield tunnel segment connecting bolts. Guarantee the survival of the strain gauge and the failure of the sensor element to achieve the effect of ensuring the waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

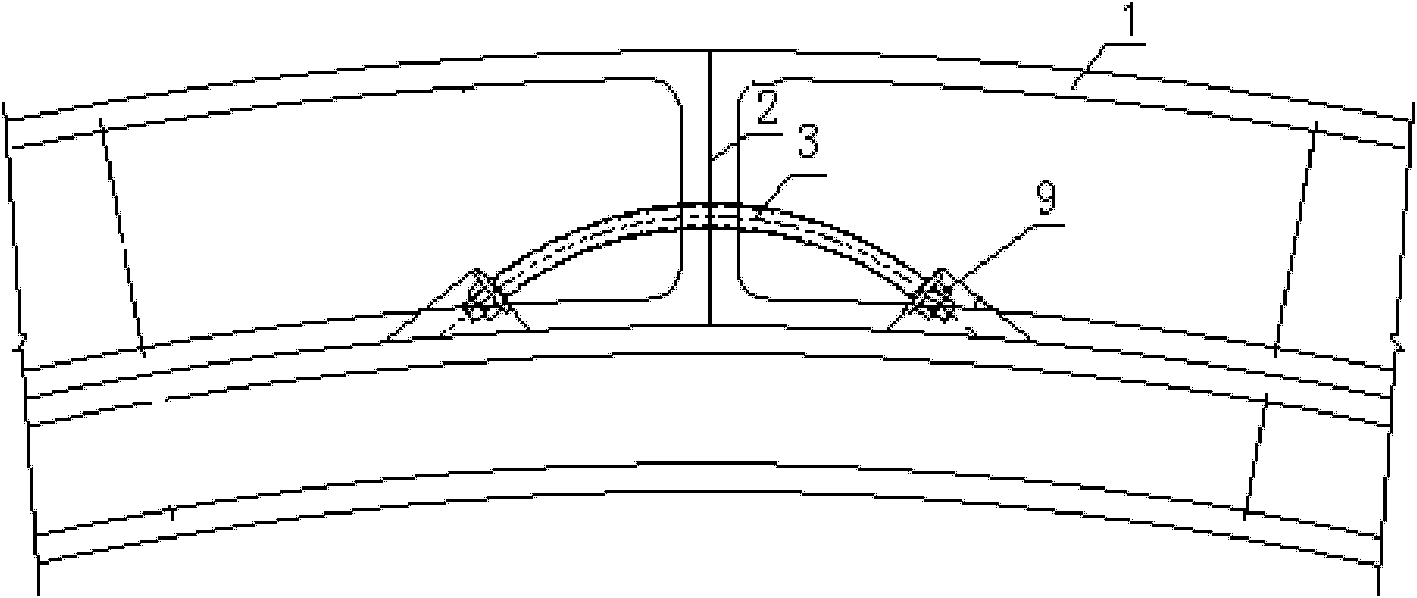

[0035] Embodiment: This embodiment relates to a method for testing the force of bolts connecting a shield tunnel segment, including the following steps:

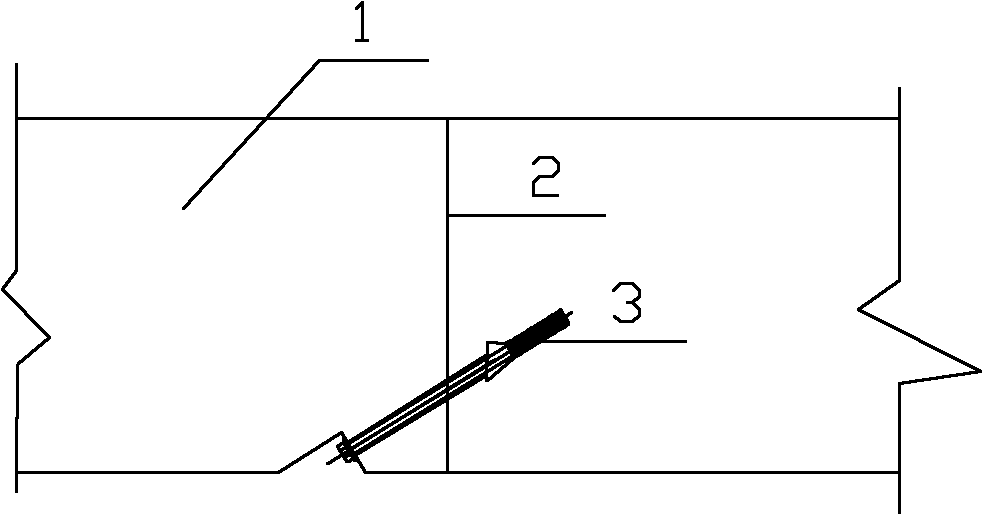

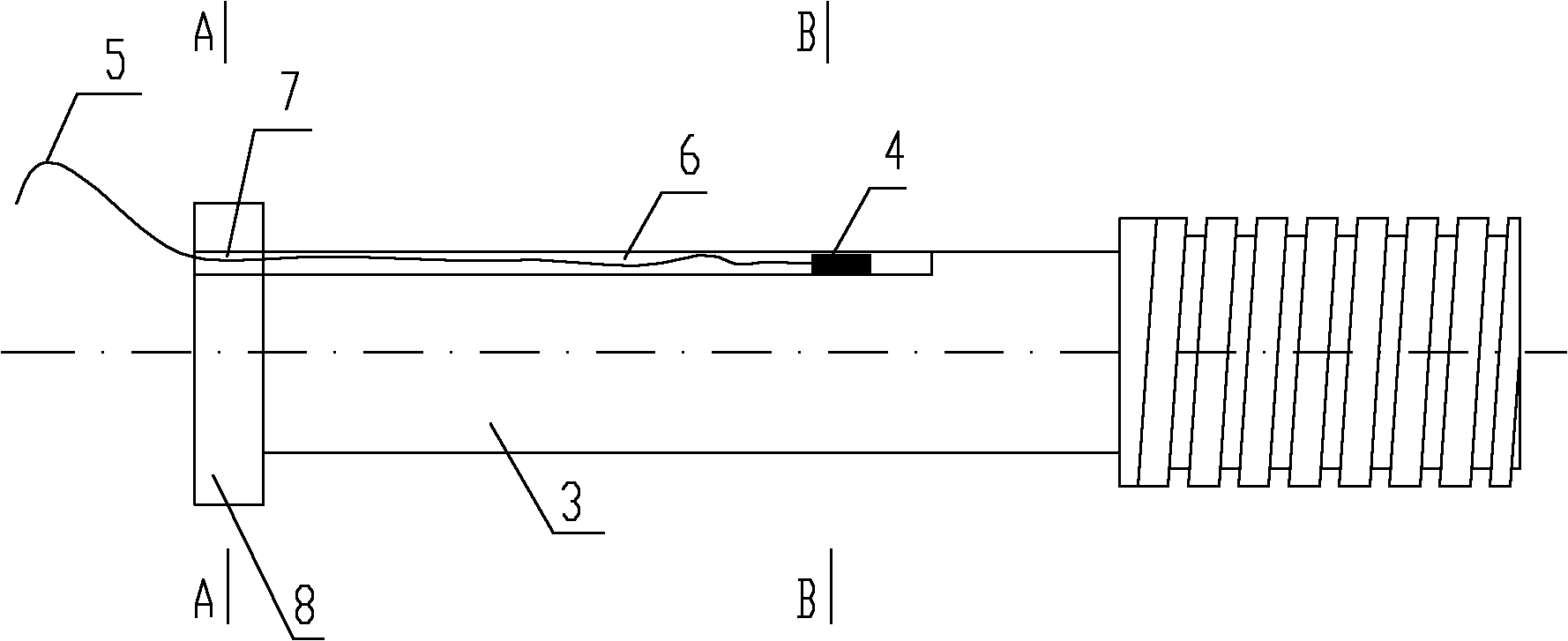

[0036] 1) Groove 6 in the axial direction on the bolt 3; if it is a single-headed oblique bolt, it is also necessary to open a wire lead-out hole 7 on the position corresponding to the groove 6 on the bolt head cap 8, see image 3 ; If it is a double-ended straight bolt or a double-ended curved bolt, it is necessary to slot 6 along the axial direction on the stud bolt, and the slot 6 is connected to any end of the stud bolt, see Figure 4 .

[0037] 2) Pre-embed the strain sensor element 4 and the wire 5 for connecting the strain sensor element in the groove 6, and encapsulate it with a sealant 10.

[0038] 3) Lead the wire 5 out of the groove of the bolt; if it is a single-headed inclined bolt, the wire 5 needs to be led out from the wire lead-out hole 7 of the bolt head cap 8, see image 3 ;If it is a stud straight bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com