Auxiliary pressurization system of internal combustion engine

A supercharging system and internal combustion engine technology, applied in the direction of internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems affecting the acceleration response characteristics of internal combustion engines, insufficient exhaust energy of the engine, and large gasoline engine speed range, etc., to eliminate turbo hysteresis effect , Improving the transient response characteristics and eliminating the hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

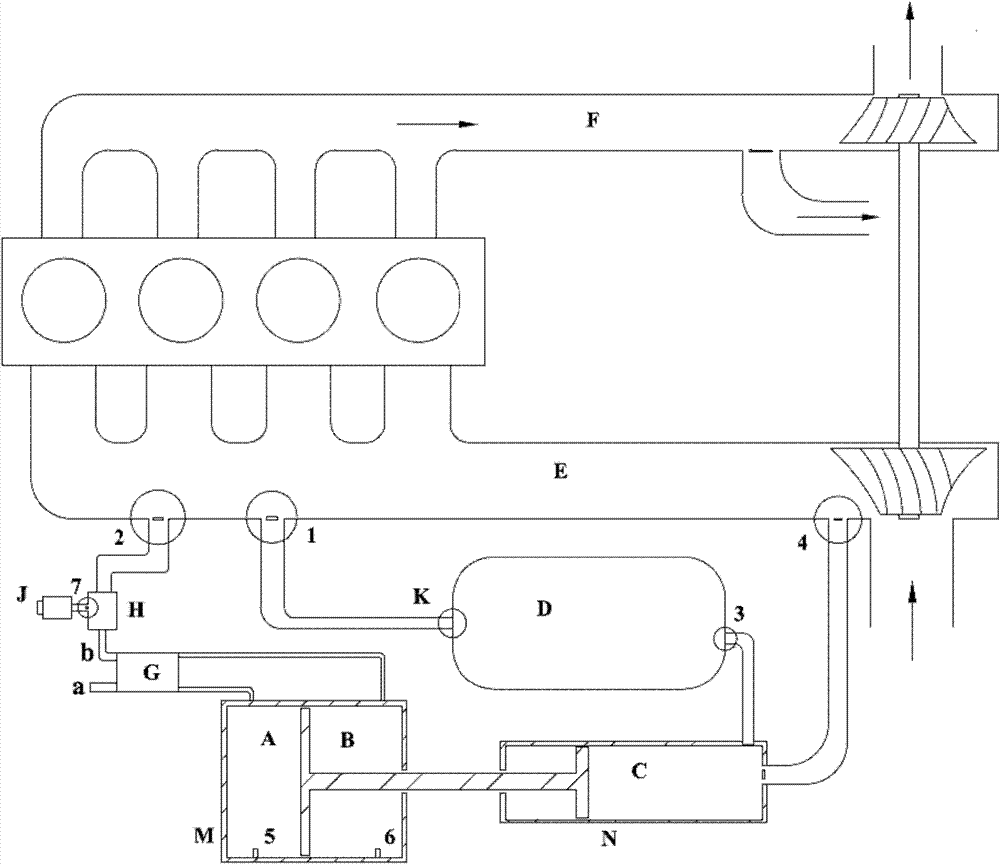

[0031] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

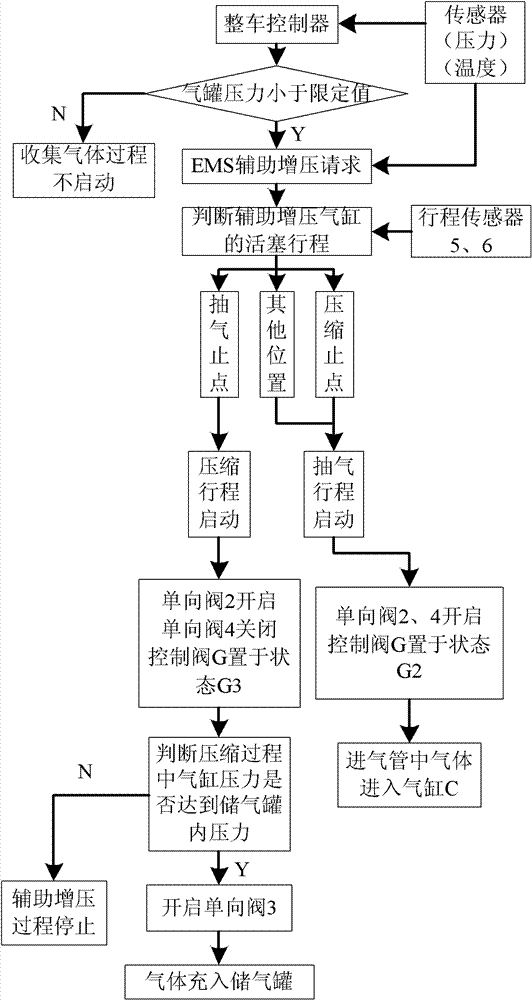

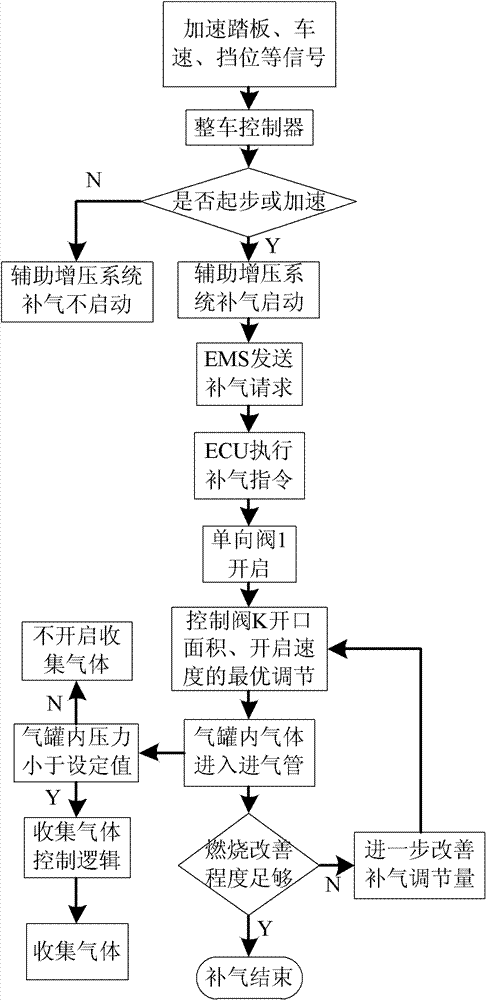

[0032] The internal combustion engine auxiliary supercharging system in this embodiment mainly solves the problem of supercharging transient response caused by turbo lag effect and the like. Its design idea is: when the turbocharger is close to or reaches the supercharged state, divert part of the pressurized gas from the intake pipe, and use the pressure difference between the system vacuum source and the atmosphere to re-pressurize this part of the intake air , store the secondary pressurized gas in a gas storage tank, and when the engine turbocharger cannot provide supercharged intake air in time (such as low speed or rapid acceleration and other transient working conditions), the gas storage tank The high-pressure gas is injected into the intake pipe to increase the intake air volume of the engine and improve the power performance of the engine, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com