Polyamide alloy nanocomposite insulation sleeve

A technology of alloy nanometer and thermal insulation sleeve, which is applied in the direction of heating/cooling of pipes, rigid pipes, and pipes, can solve the problems of environmental pollution and thermal insulation effect of outer layer thermal insulation materials, high construction cost, large surface area, etc., to save manpower and Material resources, metal resources and water resources, large construction costs, and the effect of optimizing the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

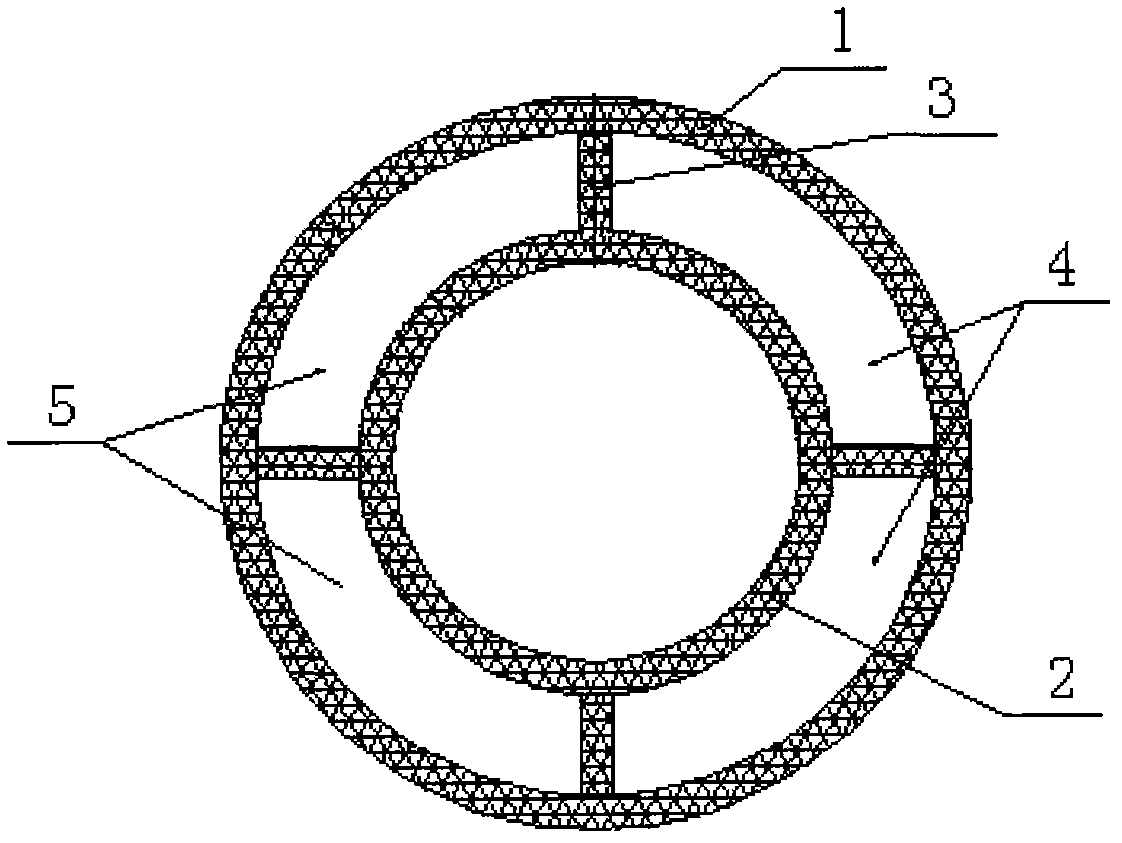

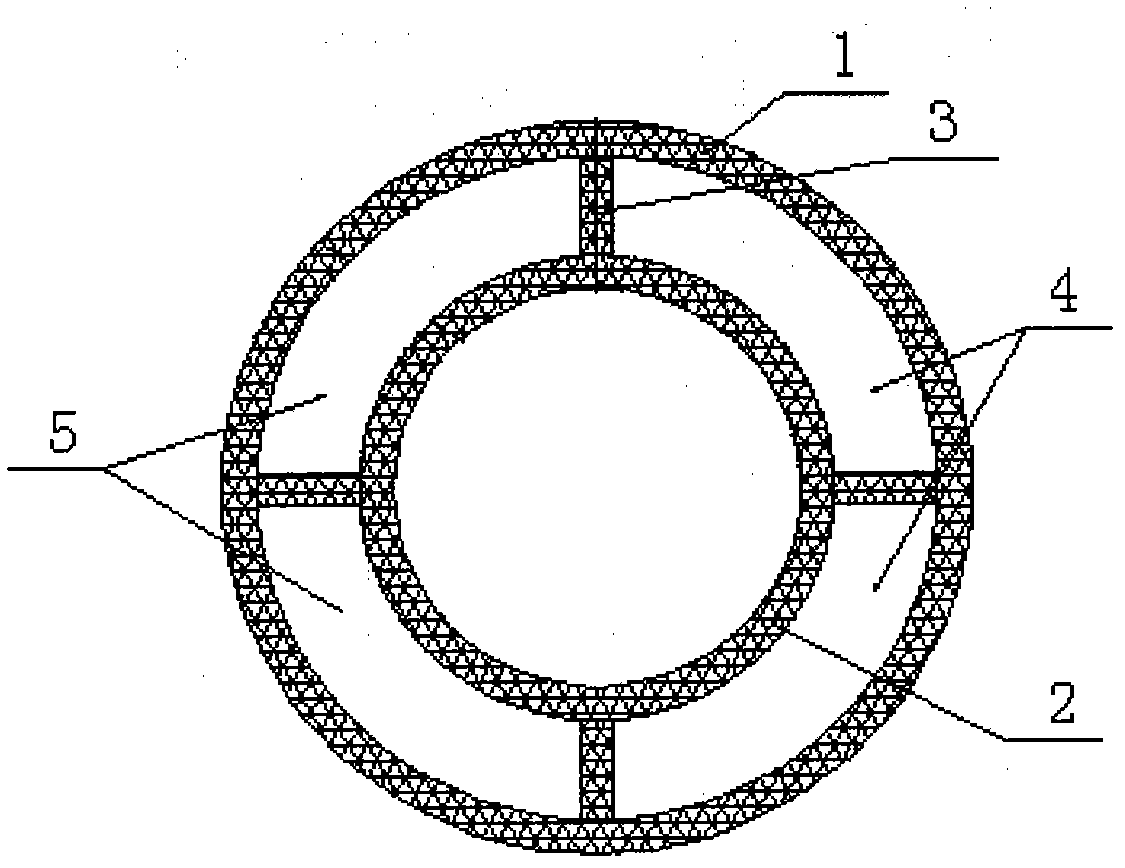

[0011] Embodiment is described below in conjunction with accompanying drawing:

[0012] see figure 1 and figure 2 , the present invention is a polyamide alloy nano-composite thermal insulation sleeve, which is a half-type thermal insulation sleeve used for petroleum transportation. The outer pipe 1 and the inner pipe 2 are coaxially socketed, and the inner pipe 2 is an oil delivery inner pipe; there are four casing interlayers 3 arranged between the outer pipe 1 and the inner pipe 2, and the outer pipe 1 and the inner pipe 2 are connected together. The inner tube 2 is fixedly connected together; the outer tube 1 and the inner tube 2 are divided into four interlayer spaces isolated from each other by the four casing interlayers 3, and the four interlayer spaces are all equal; two of the interlayer spaces are The hot water inlet pipe chamber 4, and the other two interlayer spaces are the hot water outlet pipe chamber 5. The hot water enters and exits in the interlayer space o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com