wind power equipment

A technology for wind power generation equipment and generators, which is applied in the directions of wind turbine components, wind energy power generation, wind turbines, etc., can solve the problems of affecting the life of the meshing part and other components, and the problems are not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

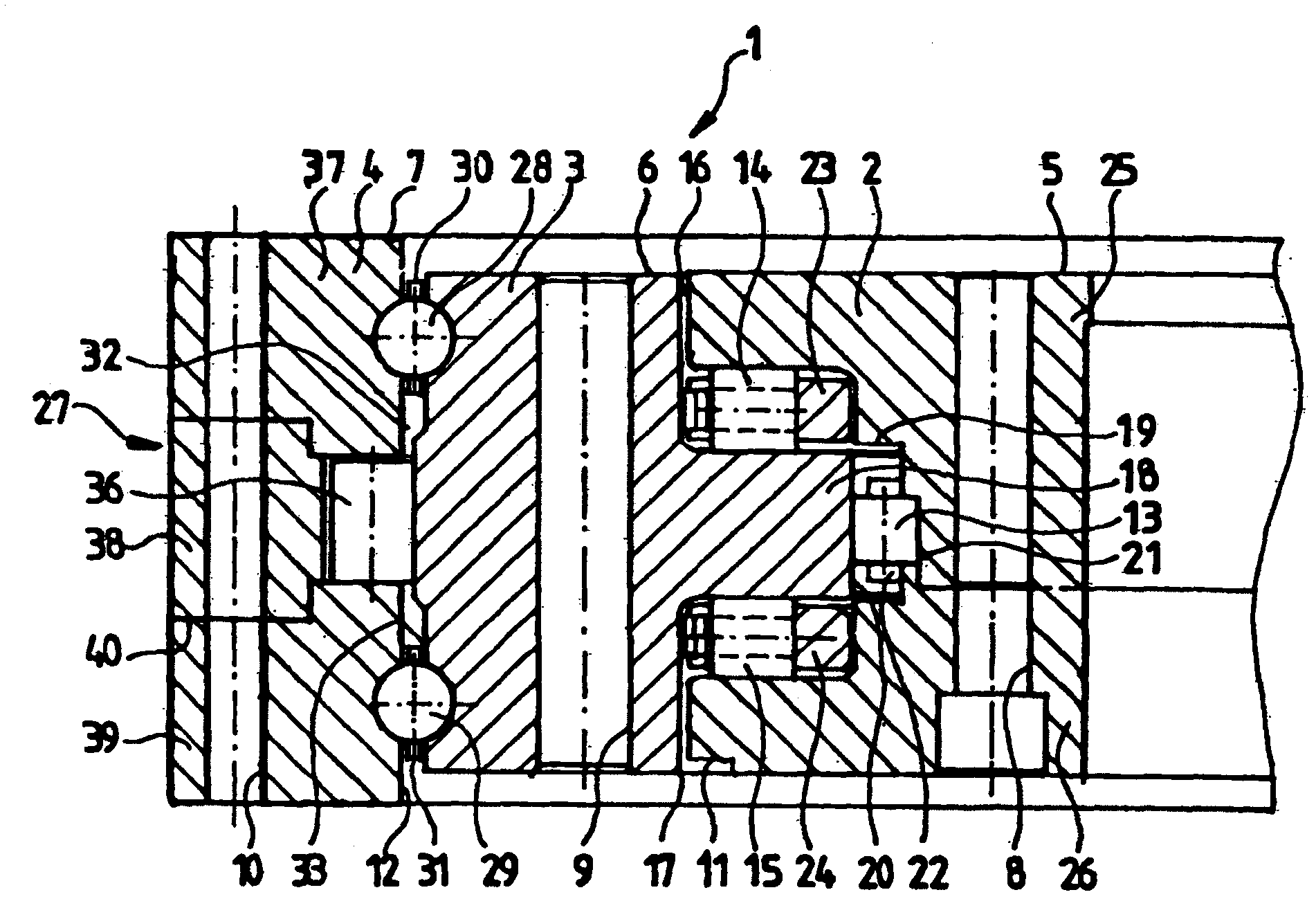

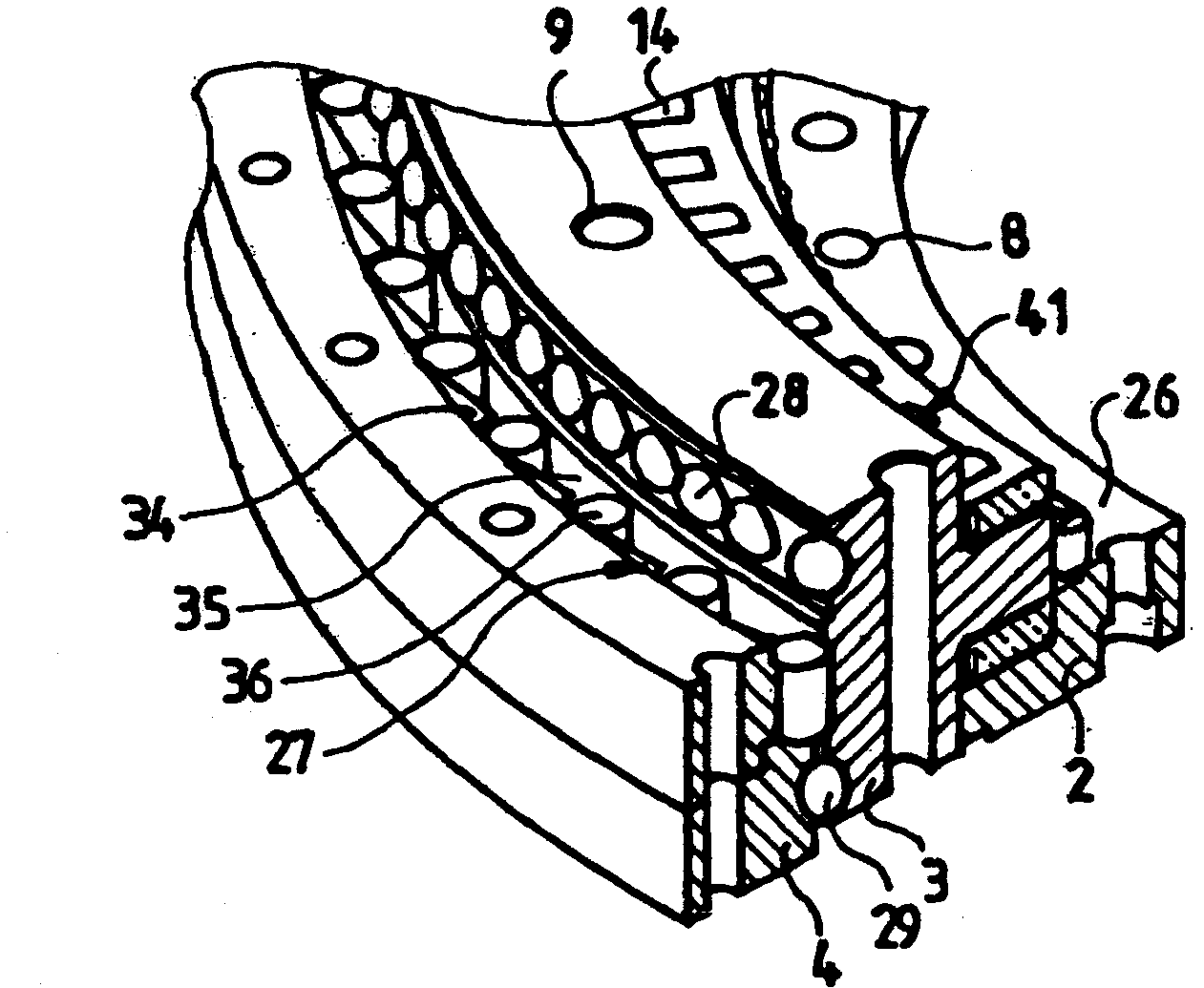

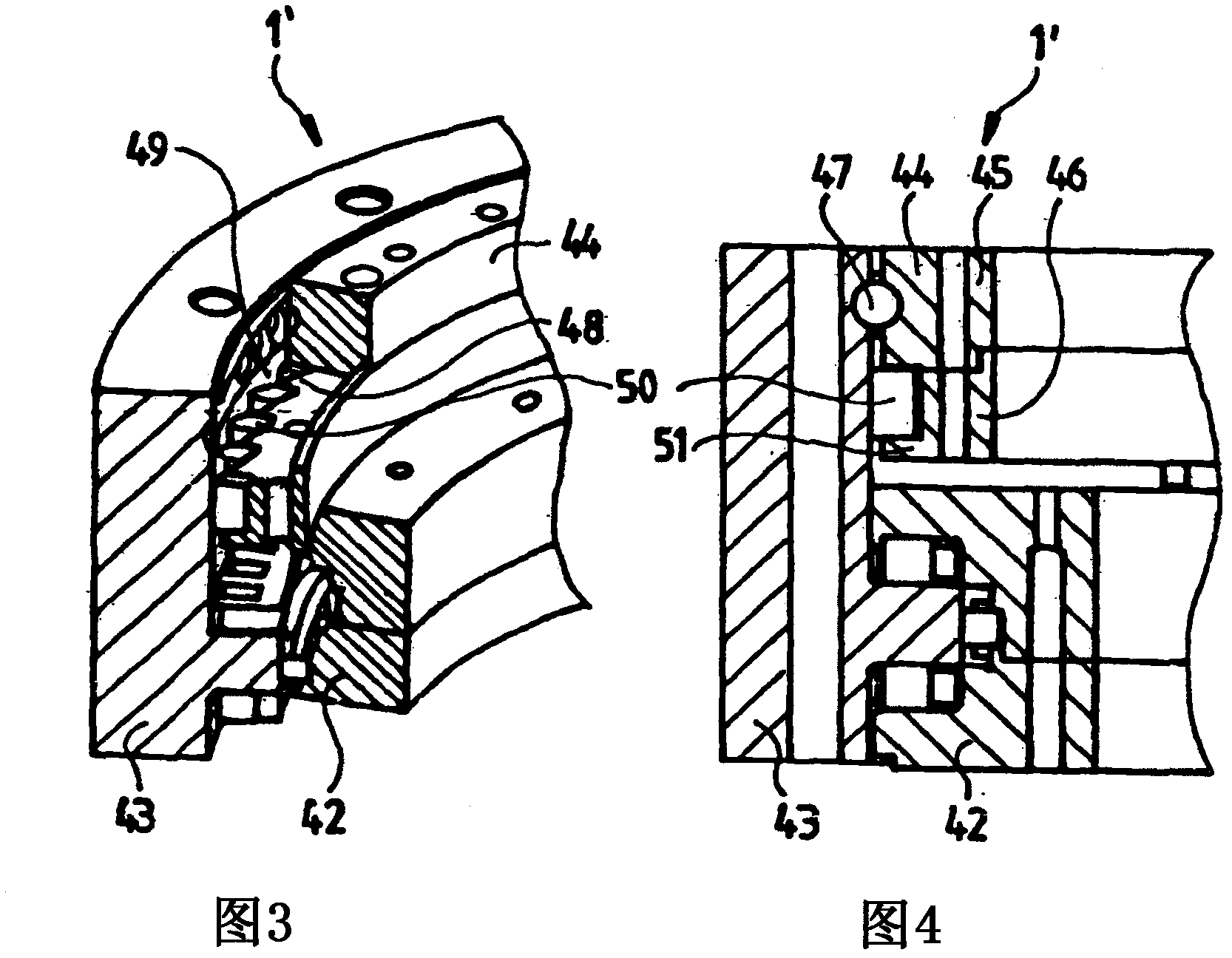

[0043] exist figure 1 2 shows, by way of example for the present invention, a sectional view of a ring of a rolling bearing 1 for a rotor of a wind power plant having a rotor with an axis of rotation pointing approximately in the direction of the wind. The rolling bearing 1 can be used as a main bearing of a wind power plant, and the rolling bearing 1 also carries the rotor hub; especially when the wind power plant is not driven, the bearing 1 can also be used as a bearing for guiding the rotor shaft, or the bearing 1 Interlock (Anschluβ) connected to the transmission or coupling of the drive train from the wind rotor to the generator - especially on the output

[0044] The bearing 1 comprises three rings 2 , 3 , 4 which are each relatively rotatable. exist figure 1 In the example in , the inner ring 2 is fixed on the frame of the machine housing, the middle ring 3 is connected to the rotor hub or rotor shaft or to the output of the transmission or coupling, and the outer ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com