Etching device, analysis device, etching treatment method, and etching treatment program

A technology of etching treatment and etching device, which is applied in the fields of electrical excitation analysis, thermal excitation analysis, material excitation analysis, etc., and can solve the problems of inability to luminous classification, inability to find waveforms, and inability to achieve classification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In addition, in all the drawings for describing the embodiments, the same members are given the same reference numerals in principle, and repeated description thereof will be omitted.

[0060] First, the outline of the present invention will be described.

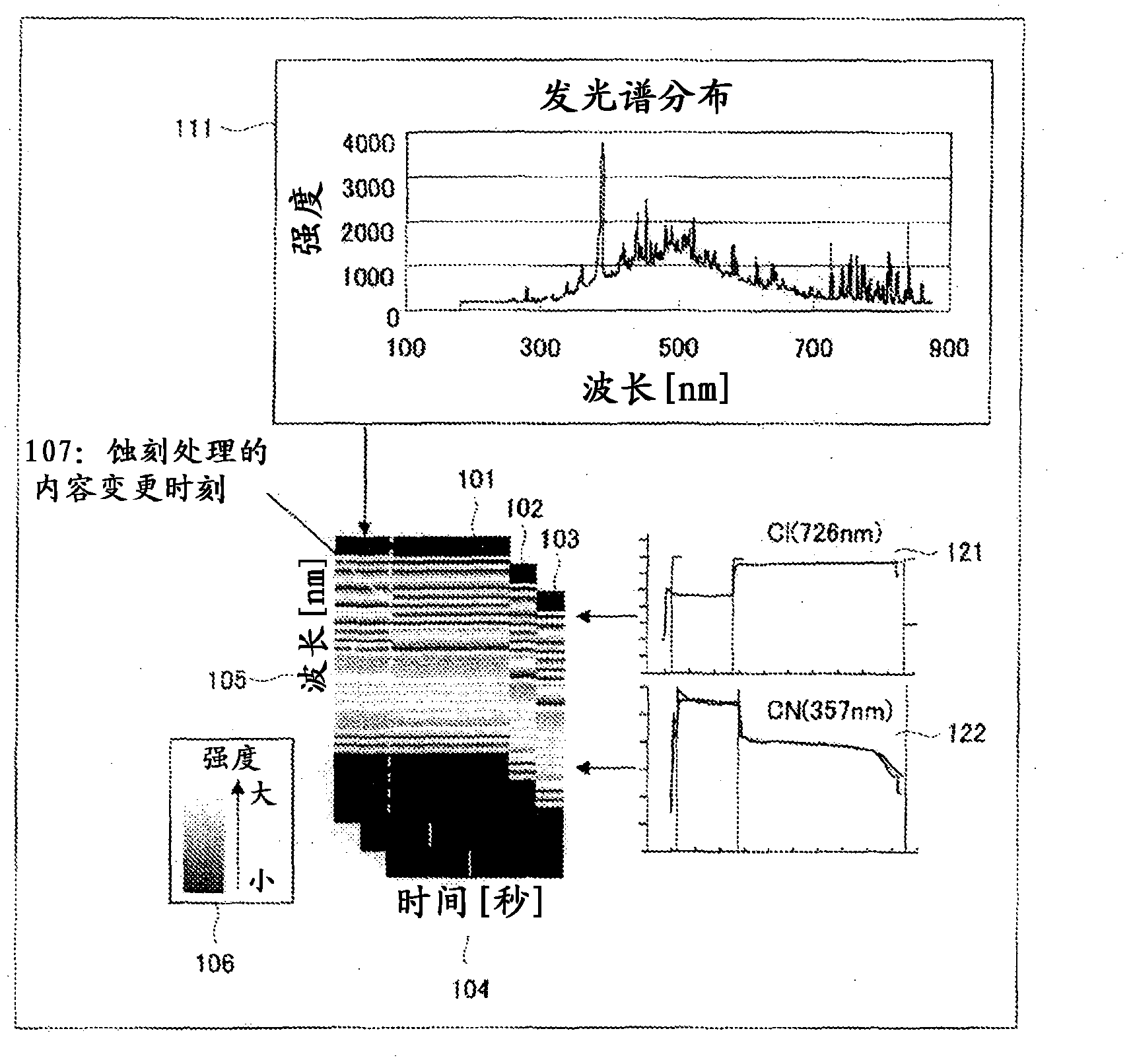

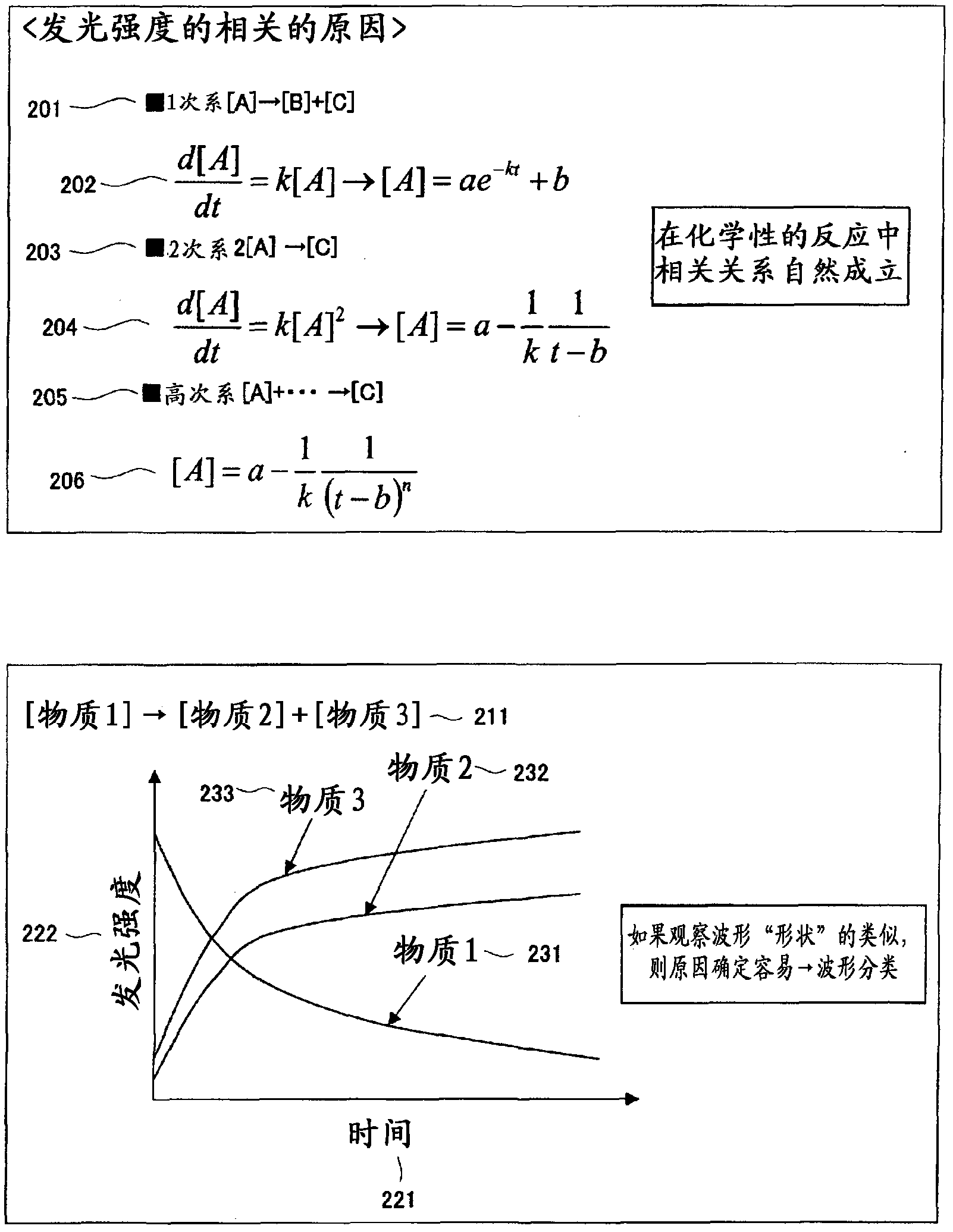

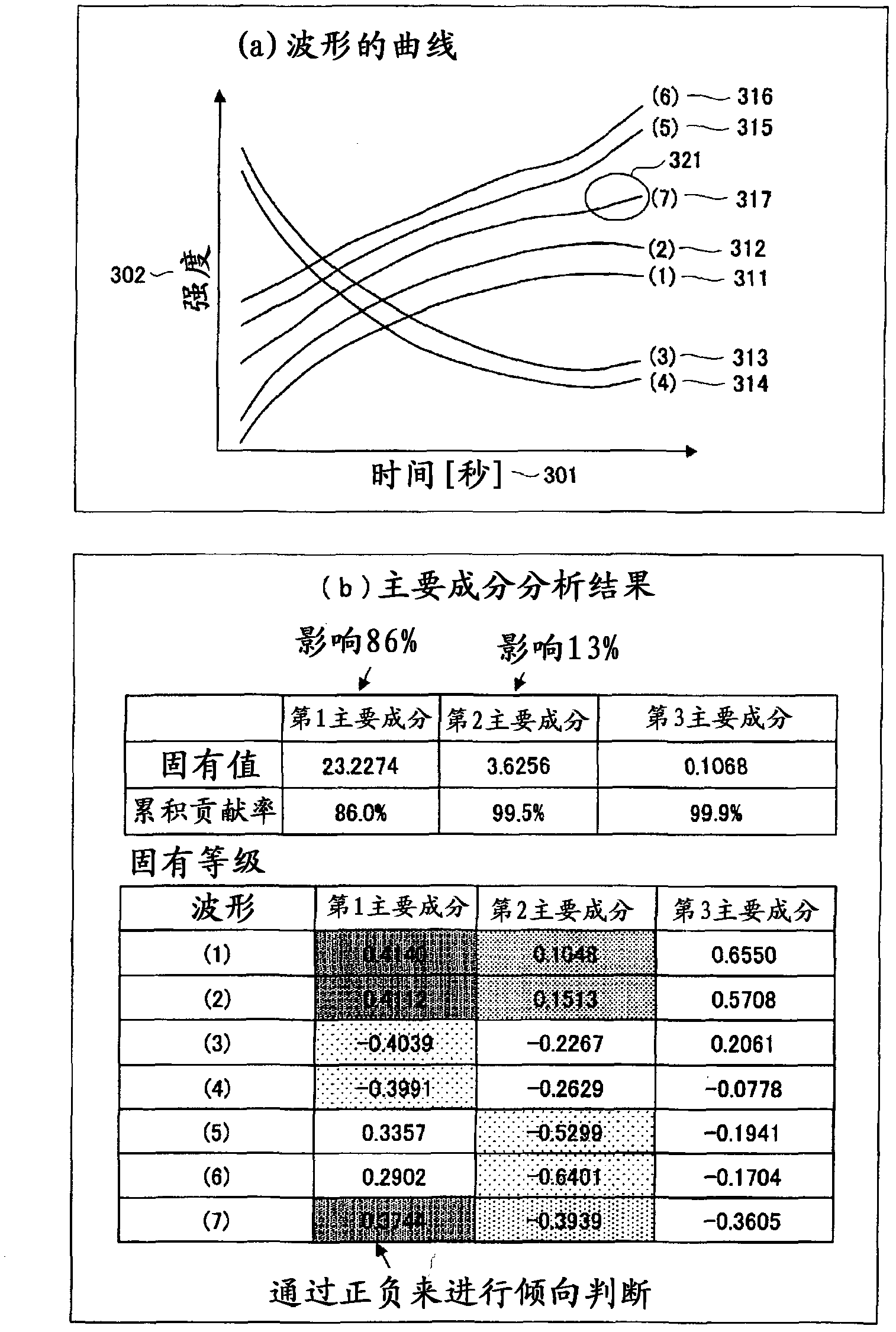

[0061] In the present invention, the etching apparatus is equipped with an optical splitter (OES), and includes means for acquiring OES data for each etching process. The light-emitting spectrometer is connected to a storage device and a database, and includes means for storing OES data in the storage device and the database. Equipped with: a unit that obtains multiple waveforms from OES data, classifies the waveforms, and obtains representative waveforms to monitor etching; a unit that judges abnormality / normality; a unit that analyzes / evaluates etching processing results; and a unit that adjusts etching pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com