Method and related apparatus for reducing pressure in a loadlock

A technology of load lock and pressure, applied in mechanical equipment, transportation and packaging, ion implantation and plating, etc., can solve the problems of complex implementation of driving devices, reliability problems of turbomolecular pumps, and high pumping noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The term "main vacuum pressure" means a pressure of less than about 0.1 Pascal obtained by main pumping. The term "secondary vacuum pressure" refers to a pressure of less than about 0.1 Pascal obtained by secondary turbomolecular pumping.

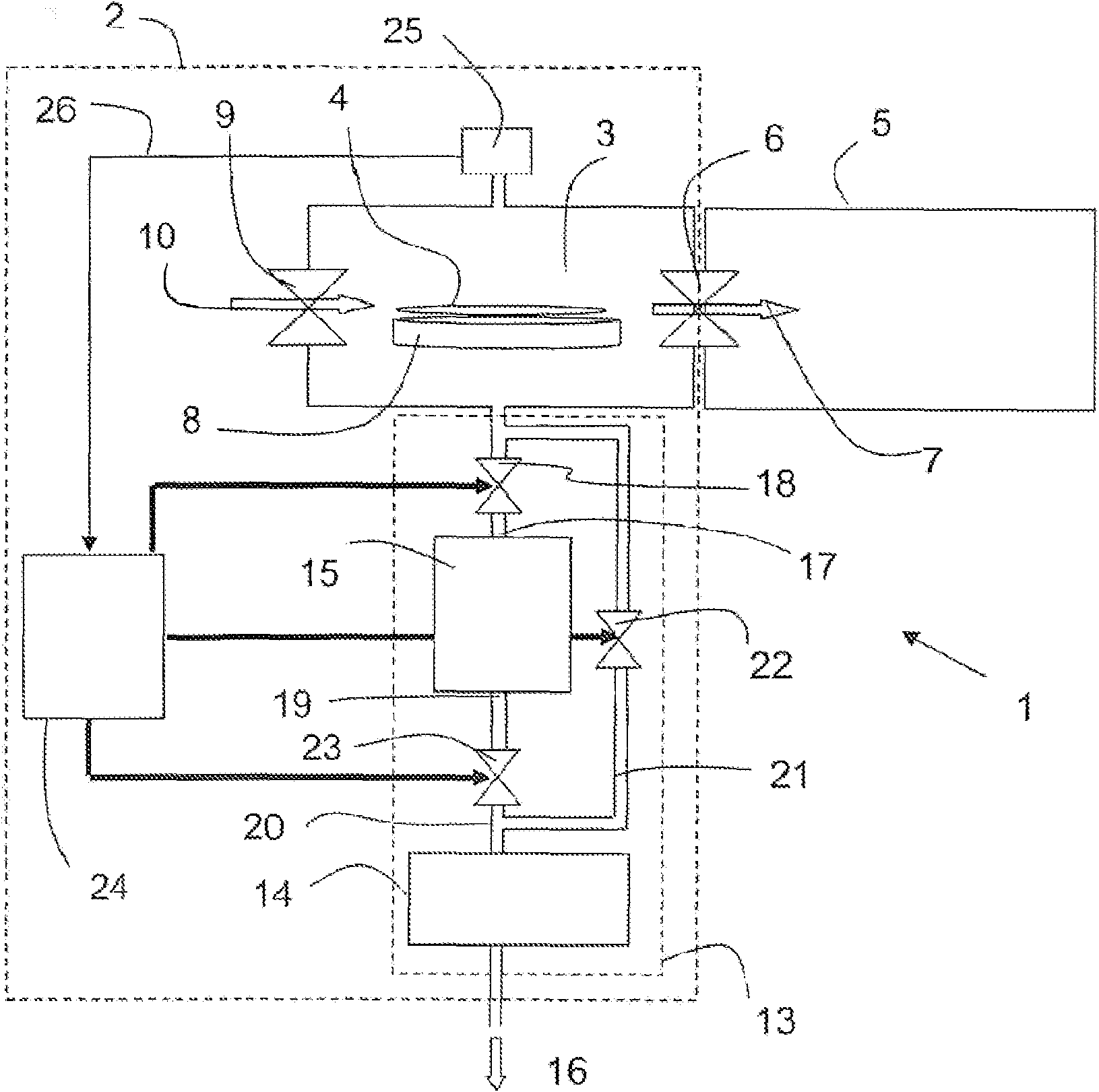

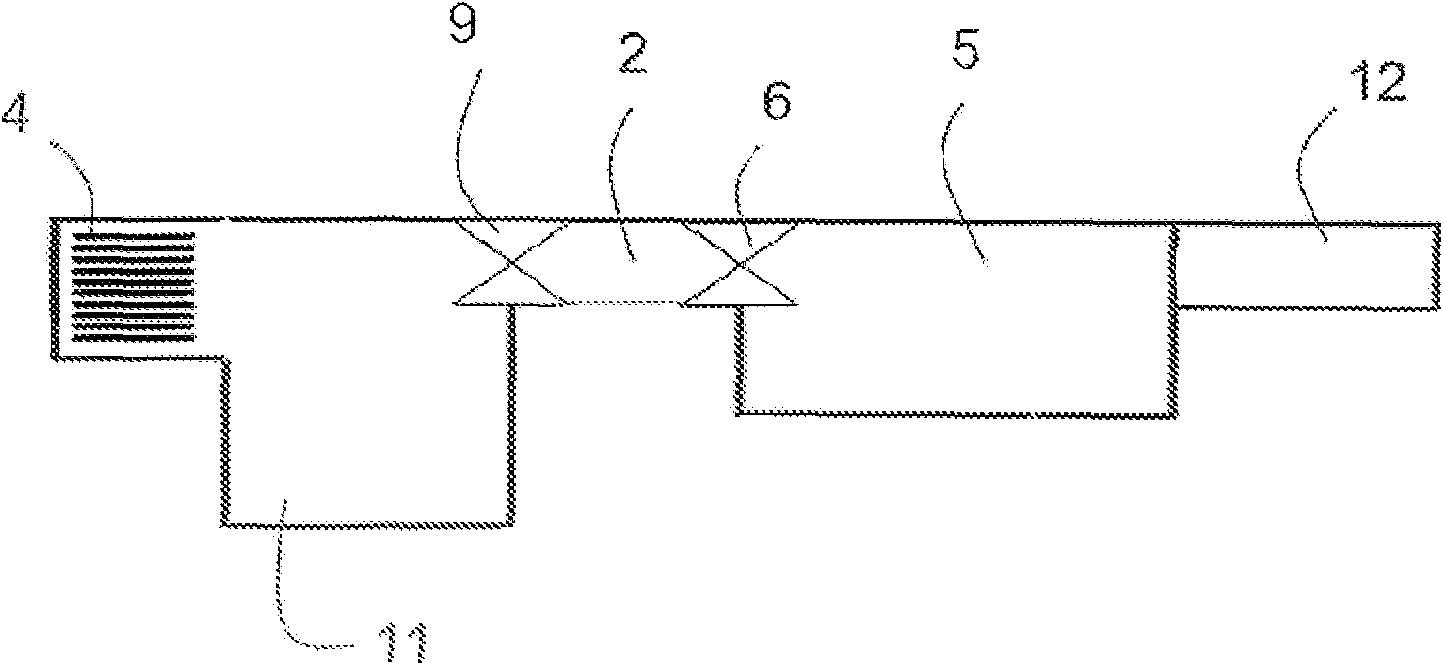

[0035] figure 1 Shown is an apparatus 1 comprising a load lock 2 comprising a chamber 3 for reducing the ambient pressure of at least one substrate 4 from atmospheric pressure to a sub-atmospheric transfer pressure.

[0036] A subatmospheric delivery pressure is, for example, a main vacuum pressure of about 0.01 Pascal.

[0037] The apparatus 1 also comprises at least one process chamber 5 communicating with the load lock 2 via a first lock door 6 for transferring substrates 4 in the direction of arrow 7 into the process chamber 5 under transfer pressure.

[0038] The load lock 2 and the processing chamber 5 comprise a substrate carrier 8 and a robot (not shown) in particular for supporting and transporting the substrate 4 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com