Serrated sliding automatic telescopic honing head

An automatic telescopic and honing head technology, applied in the direction of honing tools, etc., can solve the problems of drum shape, strain, scratches in the inner hole of the workpiece, etc., and achieve the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

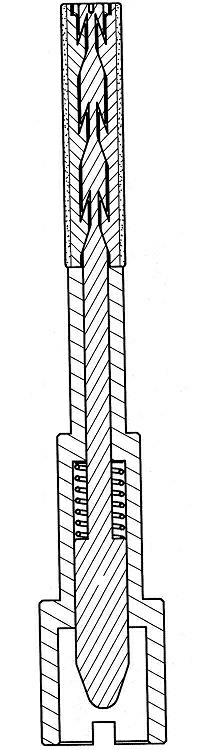

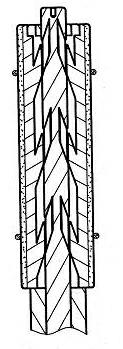

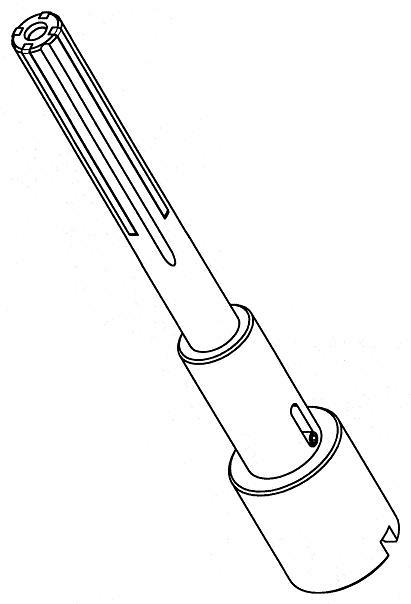

[0012] The sawtooth mandrel 2 is located in the honing head casing 1, the limit screw 3 is fixedly connected with the serrated mandrel 2, the limit screw is slidingly connected with the groove on the honing head casing, the spring 4 is sleeved on the serrated mandrel, and the working surface of the bottom plate 5 is installed in the long groove at the front end of the honing head jacket. The base plate working surface 5 adopts a zigzag structure and is supported by three taper slopes.

[0013] Working principle: After the honing head is assembled, it is installed on the power head of the machine tool. During honing, under the action of the feed mechanism of the machine tool, the sawtooth mandrel moves forward, and the working surface of the base plate expands to grind the workpiece. When in the original position, the sawtooth mandrel pulls the working surface of the bottom plate back to the original state under the active force of the spring.

[0014] When replacing the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com