Track transfer system for containers

A container and track technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of high maintenance costs, manpower consumption, high investment costs, etc., achieve energy saving and environmental protection, simple and practical structure, and reduce operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

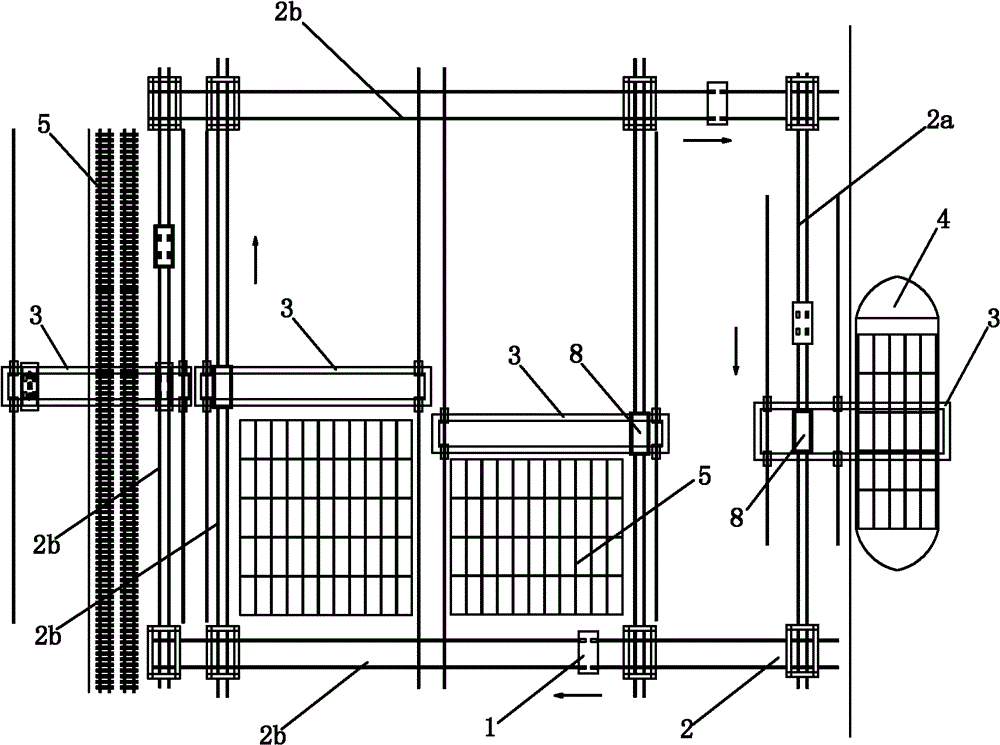

[0034] A container track transfer system is provided, comprising: a container transfer trolley 1, a track 2 and a lifting device 3, the lifting device 3 is respectively arranged at a container transfer station 4 and a container destination 5, and the container transfer station 4 passes through the track 2 is connected to the container destination 5, and the container transfer trolley 1 is arranged on the track 2. The track 2 includes a transfer track 2a and a destination track 2b, and a transfer device 6 for the transfer of the container 8 is provided at the junction of the transfer track 2a and the destination track 2b. Both the transfer track 2a and the destination track 2b are single-layer tracks. The rail transfer device 6 includes a roller steering device arranged between the bottom of the container transfer trolley 1 and the rollers of the container transfer trolley 1 and a telescopic support rod arranged at the bottom of the container transfer trolley 1 . Of course, th...

Embodiment 2

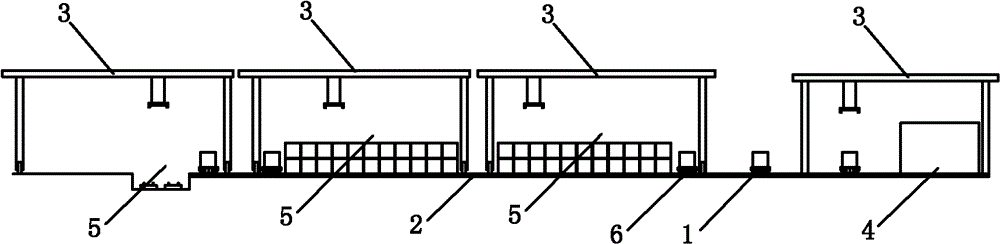

[0037] A container track transfer system is provided, comprising: a container transfer trolley 1, a track 2 and a lifting device 3, the lifting device 3 is respectively arranged at a container transfer station 4 and a container destination 5, and the container transfer station 4 passes through the track 2 is connected to the container destination 5, and the container transfer trolley 1 is arranged on the track 2. The track 2 includes a transfer track 2a and a destination track 2b, and a transfer device 6 for the transfer of the container 8 is provided at the junction of the transfer track 2a and the destination track 2b. The transfer track 2a is a single-layer track, and the destination track 2b is a double-layer track. An elevator 7 is provided at both ends of the destination track 2b. The rail transfer device 6 includes a roller steering device arranged between the bottom of the container transfer trolley 1 and the rollers of the container transfer trolley 1 and a telescopic...

Embodiment 3

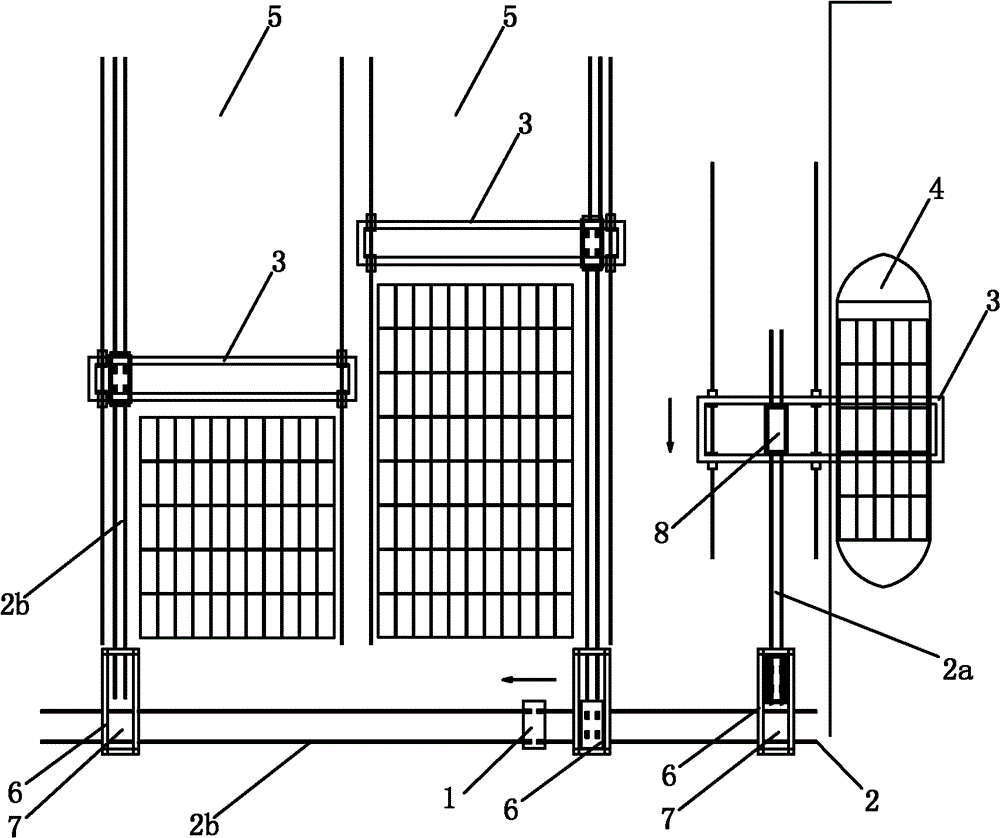

[0040] A container track transfer system is provided, comprising: a container transfer trolley 1, a track 2 and a lifting device 3, the lifting device 3 is respectively arranged at a container transfer station 4 and a container destination 5, and the container transfer station 4 passes through the track 2 is connected to the container destination 5, and the container transfer trolley 1 is arranged on the track 2. The track 2 includes a transfer track 2a and a destination track 2b, and a transfer device 6 for the transfer of the container 8 is provided at the junction of the transfer track 2a and the destination track 2b. The destination track 2b is a single-layer track, the transfer track 2a is a double-layer track, and an elevator 7 is respectively provided at both ends of the transfer track 2a. The rail transfer device 6 includes a roller steering device arranged between the bottom of the container transfer trolley 1 and the rollers of the container transfer trolley 1 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com