Inner single-blade type capping method and mechanism

A capping and single-knife technology, applied in the direction of flanged bottle caps, etc., can solve the problems of difficult to ensure the quality of capping, heavy adjustment workload, difficult to increase production, etc., to achieve improved capping effect, less moving parts, and structural small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

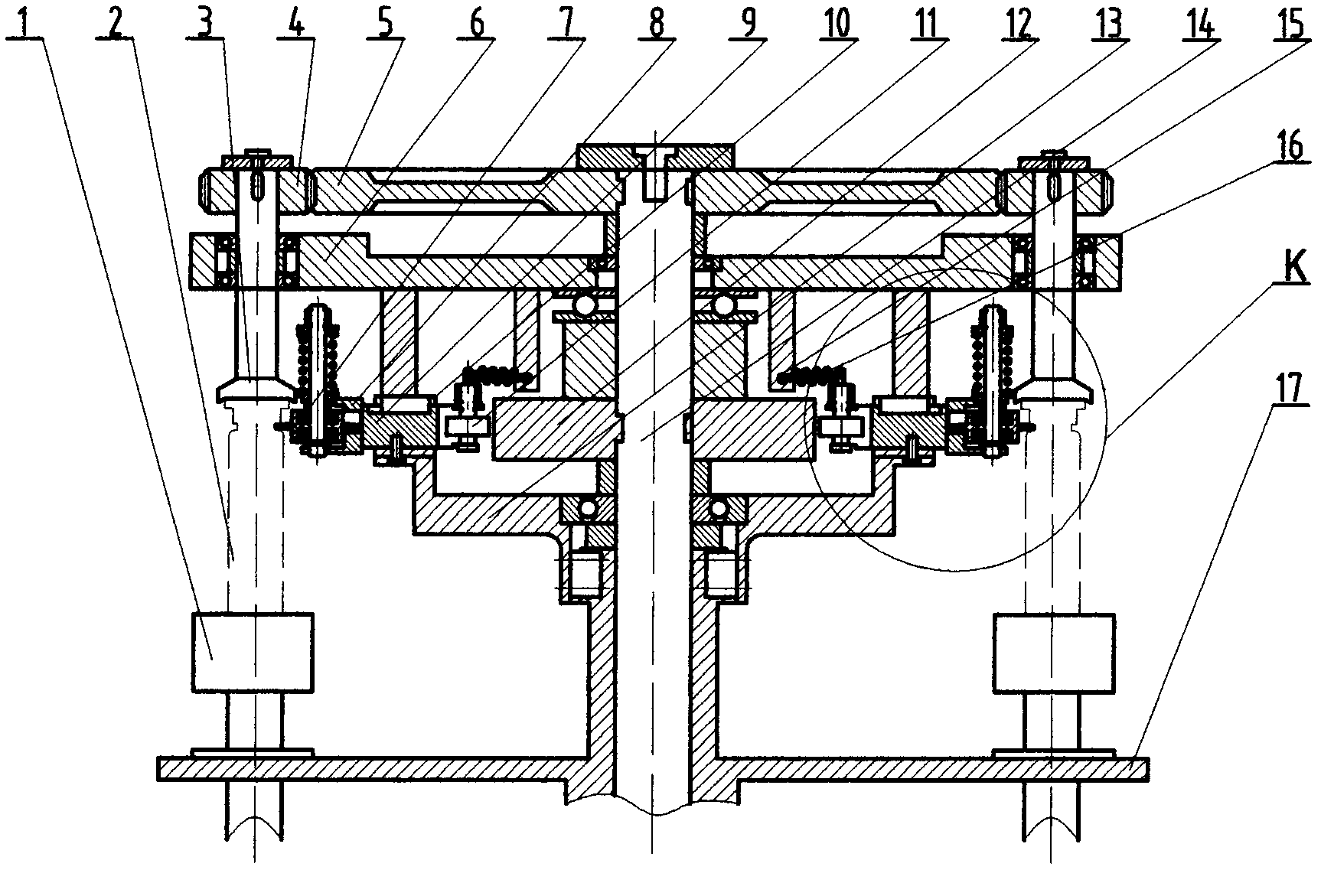

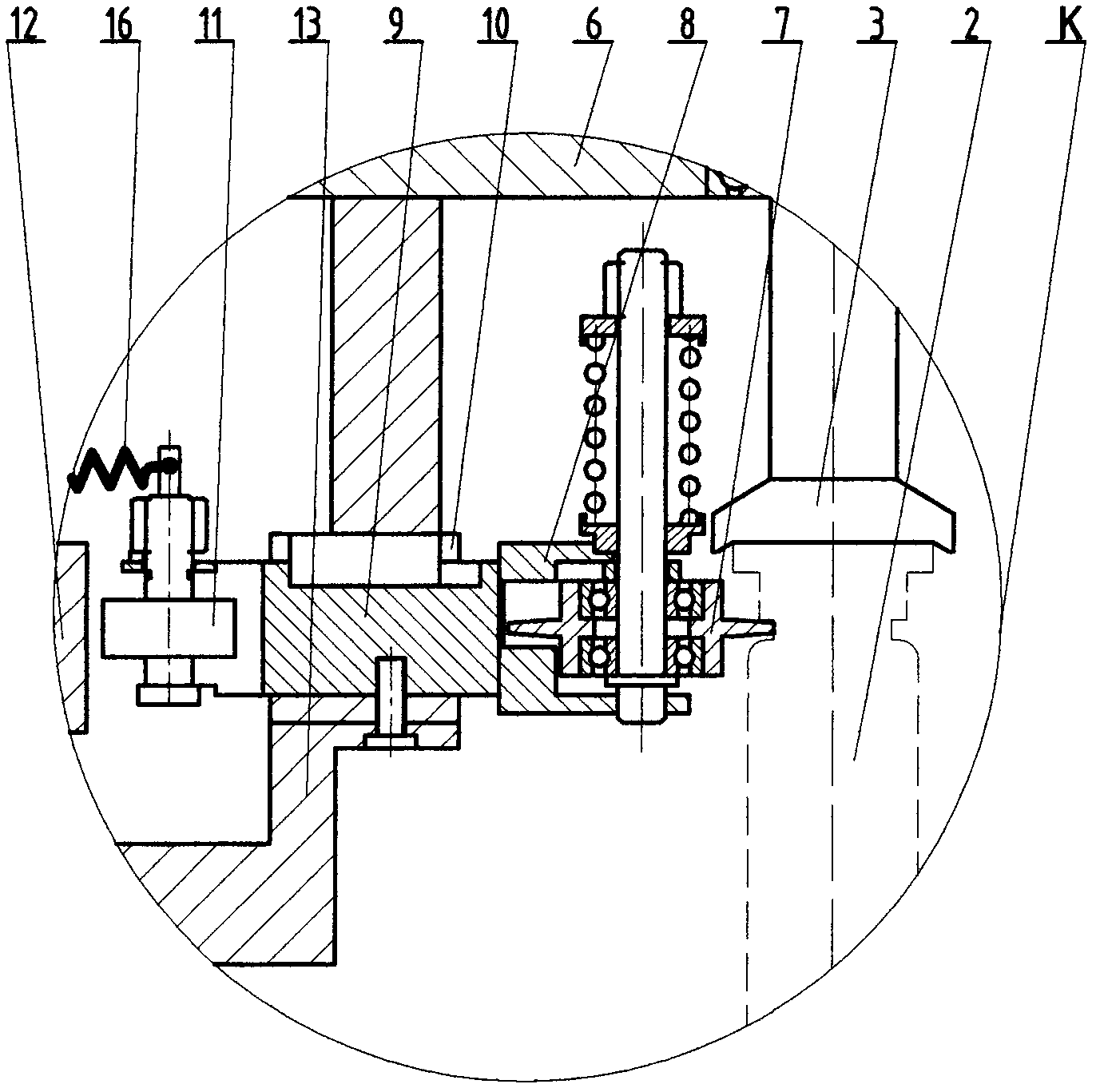

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

[0018] The inner single knife type capping method of the present embodiment, its capping process is as follows:

[0019] A. Firstly, the support plate 13 and the tray 6 are driven by the large turntable 17, together with the guide seat 10 installed on the edge of the support plate and the capping head 3 installed in the shaft hole on the edge of the tray and the capping head 3 installed in the shaft hole on the edge of the large turntable The bottle holder assembly 1 rotates around the central axis 14 together, and the guide seat 10 drives the roller guide rod 9 mounted therein to rotate together with the rolling knife seat 8 and the rolling knife 7; at the same time, the capping head installed on the upper end of the capping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com