Laminate film-forming aerobic fermentation tank and fermentation method thereof

A technology for aerobic fermentation and fermenter, which is applied to the layer-type film-forming continuous aerobic fermenter and its fermentation field, can solve the problems of incapable of continuous production, difficult control of fermentation conditions, unstable product quality, etc., and achieves production and cleaning. Convenience, reliable equipment operation, and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

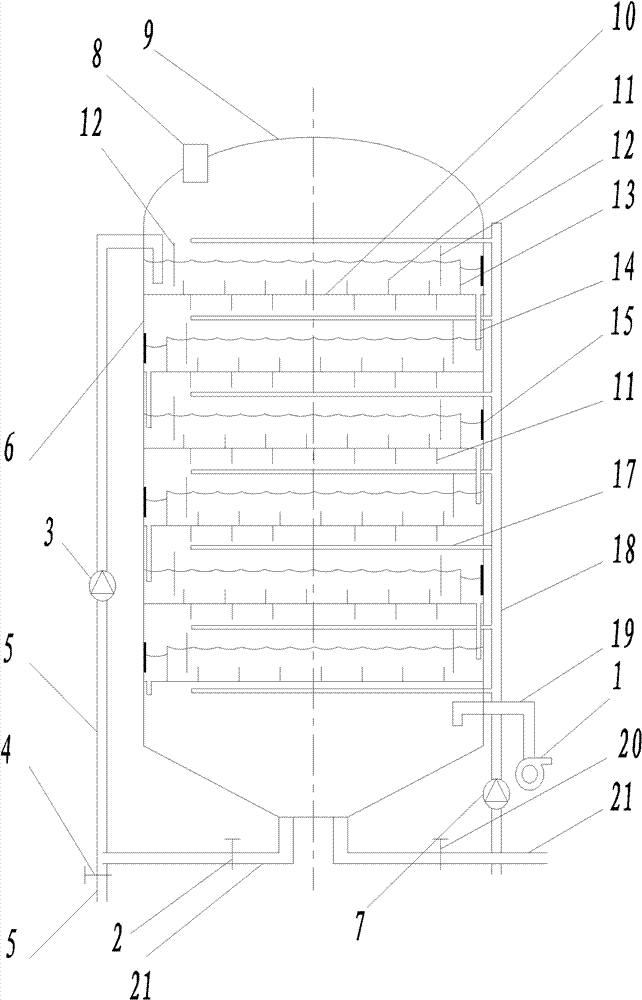

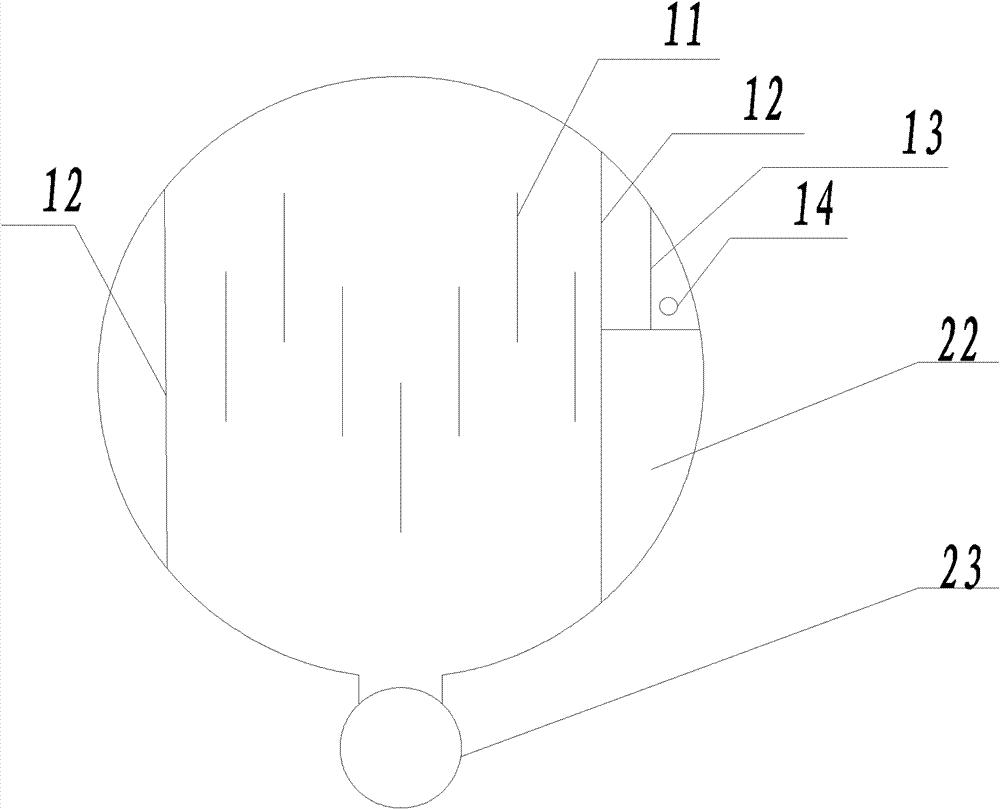

[0033] like figure 1 , figure 2 As shown in the figure, a continuous aerobic fermenter of layer plate type film formation includes a tank body 6, a top cover 9, a layer plate 10, a baffle plate 11, a baffle plate with holes at the bottom 12, an overflow plate 13, a guide pipe 14, an inlet Feed pipe 5, discharge pipe 21, intake pipe 19, exhaust pipe 8, gas supply system 1, material pump 3 and online acidity detector; the gas supply system 1 used in this example is a fan, and the model of the online acidity detector is : HANNAHI991401; wherein, a top cover 9 and a feed pipe 5 are installed on the top of the tank body 6, and one end of the feed pipe 5 is connected to the feed pump 3. This structure is used for the fermentation liquid to flow from top to bottom while fermenting, and the feed pump 3. The fermented liquid in the feed pipe 5 is provided with the power to rise, the exhaust pipe 8 is installed on the top cover 9, and 6 laminates 10 are horizontally installed in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com