a solar collector

A technology of solar heat collectors and vacuum heat collector tubes, which is applied in the directions of solar heat collectors, solar thermal energy, and solar heat collectors using working fluids, etc., and can solve the problems of storage, packaging, transportation, installation, maintenance The commercialization of solar water heaters is low, and it is impossible to solve the problems of axial deformation of connecting pipelines, which is conducive to popularization and application, improving operability, and reducing axial deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

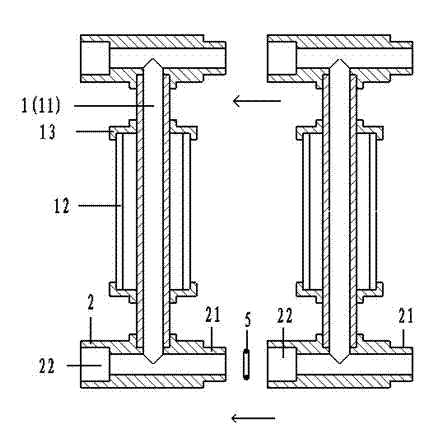

[0022] Such as figure 1 as shown,

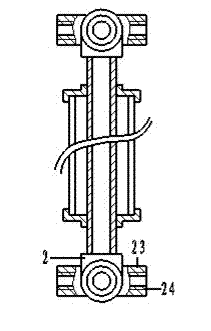

[0023] On the bracket (not shown in the figure), there is a group of vacuum heat collecting tubes 1 arranged side by side. The end cap 13 constitutes. A special tee joint 2 is arranged between the two pipe ends of the metal inner pipe, and one end of the two axial ends of the special tee joint is provided with a shaft shoulder 21, and the other end is provided with a shaft hole 22; The pipe ends are welded, two-to-two special tee joints, the shaft shoulder and the shaft hole are plugged in, and the joint is sealed with a sealing ring 3. In this way, a group of metal inner pipes and the inner pipes of special three-way joints connected in series constitute the inlet and outlet water flow channels of the heat collector in a split type.

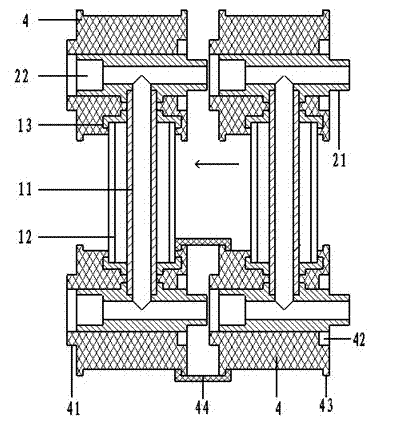

[0024] Such as figure 2 as shown,

[0025] The airtight end cap 13 between each metal inner pipe 11 and the glass outer pipe 12, and the metal inner pipe exposed outside the airtight end cap, and the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com