A segmented capacitive liquid level sensor and its liquid level measurement method

A technology of liquid level sensor and segmental capacitance, which is applied in the direction of liquid level indicator for physical variable measurement, can solve the problems affecting the accuracy and reliability of liquid level height, inconvenient communication, large interface measurement error, etc., and achieve friendly Human-computer interaction and communication, the realization of computer remote monitoring, and the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The structural features of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

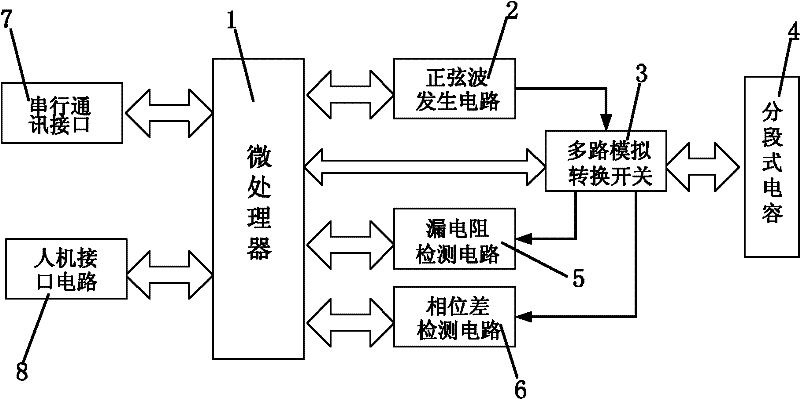

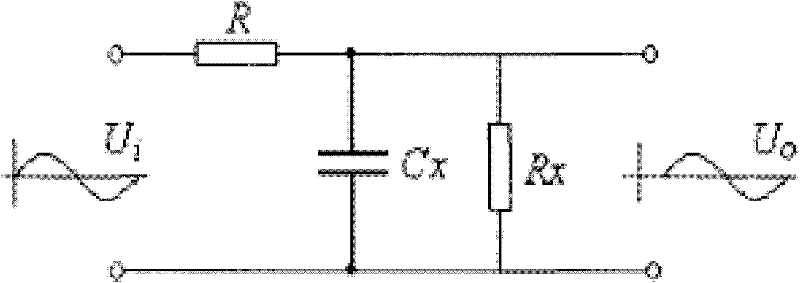

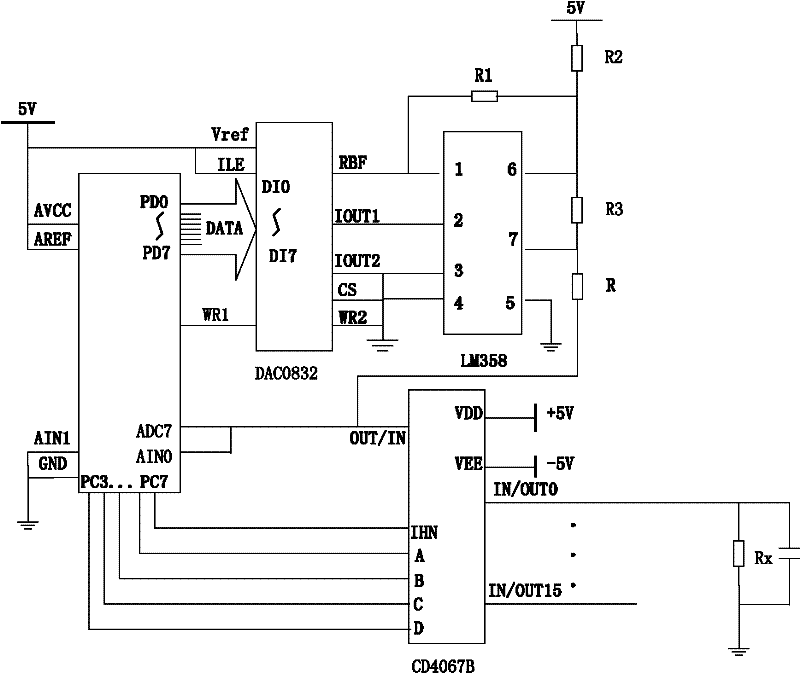

[0039] figure 1 It is a structural schematic diagram of the segmented capacitive liquid level sensor of the present invention. Such as figure 1 As shown, the segmented capacitive liquid level sensor of the present invention includes: a microprocessor 1, a sine wave generating circuit 2 connected to the microprocessor 1, and a multi-channel circuit connected to the microprocessor 1 and the sine wave generating circuit 2 The transfer switch 3 is a segmented capacitor 4 connected to the multi-way switch 3. The segmented capacitor 4 is composed of at least two mutually insulated capacitor arrangements. The multi-way switch 3 is connected to the segmented capacitor respectively. For each section of capacitance 401 in the capacitor 4, a leakage resistance detection circuit 5 and a phase difference detection circuit 6 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com