Dynamic Membrane Bioreactor Coarse Mesh Filter Membrane Filtration Resistance Test Device and Test Method

A technology of bioreactor and filtration resistance, which is applied in the direction of measuring devices, scientific instruments, suspension and porous material analysis, etc. It can solve the problems that the filtration resistance of coarse mesh membrane is difficult to test, etc., and achieve low cost, optimized development and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

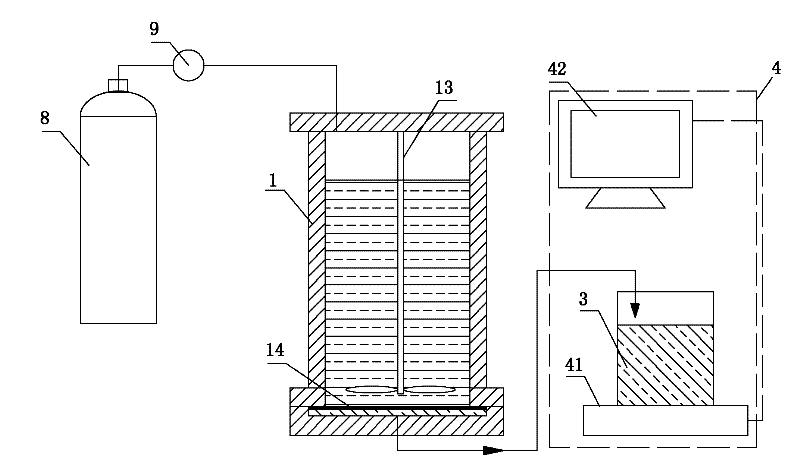

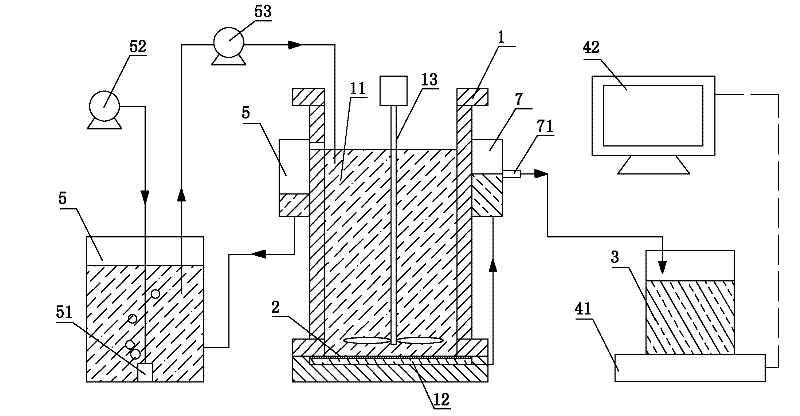

[0033] Such as figure 2 As shown, this dynamic membrane bioreactor coarse-mesh filter membrane filtration resistance test device includes a filter tank 1, a filtrate collection device 3 and a detection device 4 for detecting changes in the filtrate collection device, and the filter tank 1 is equipped with a coarse-mesh filter near the bottom. Membrane 2, described coarse mesh filter membrane 2 divides filter pool 1 into the sludge suspension region 11 at the upper end of coarse mesh filter membrane 2 and the filtrate region 12 at the lower end of coarse mesh filter membrane 2; the filtrate in the filtrate region is collected into filtrate A collection device 3 , and an aeration tank 5 for sludge cultivation is arranged outside the filter tank 1 , and the sludge suspension in the aeration tank 5 is continuously transported into the sludge suspension area 11 of the filter tank 1 .

[0034] A microporous aeration head 51 is arranged in the aeration tank 5, and the microporous ae...

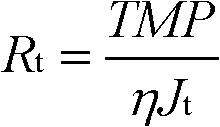

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Filter resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com