A bonding method for micro-optical components

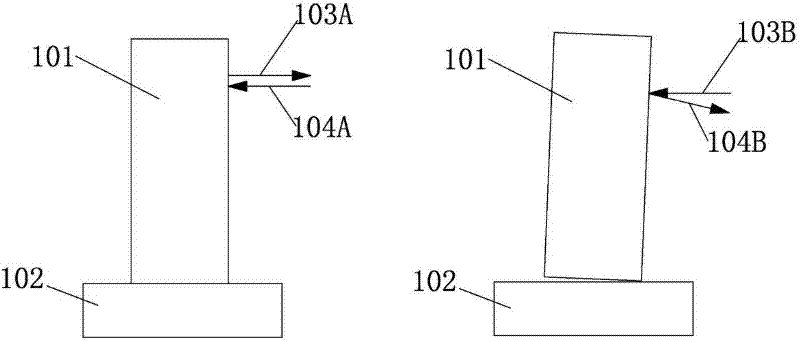

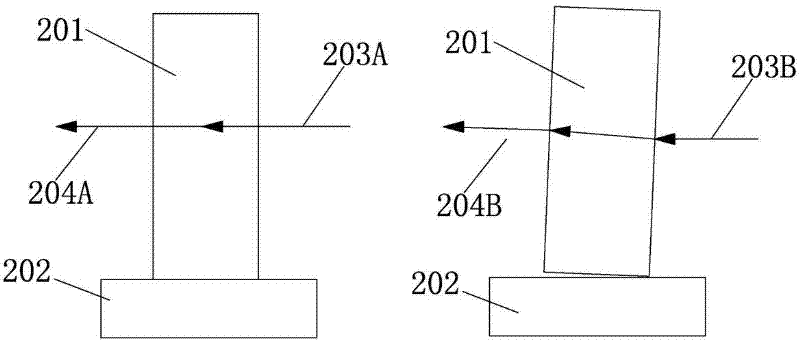

A bonding method and micro-optical technology, applied in optical components, optics, installation, etc., can solve problems such as inconsistent expansion coefficient, uneven thickness of glue layer or solder layer, and angle of incident light 203B, etc., and achieve good temperature stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

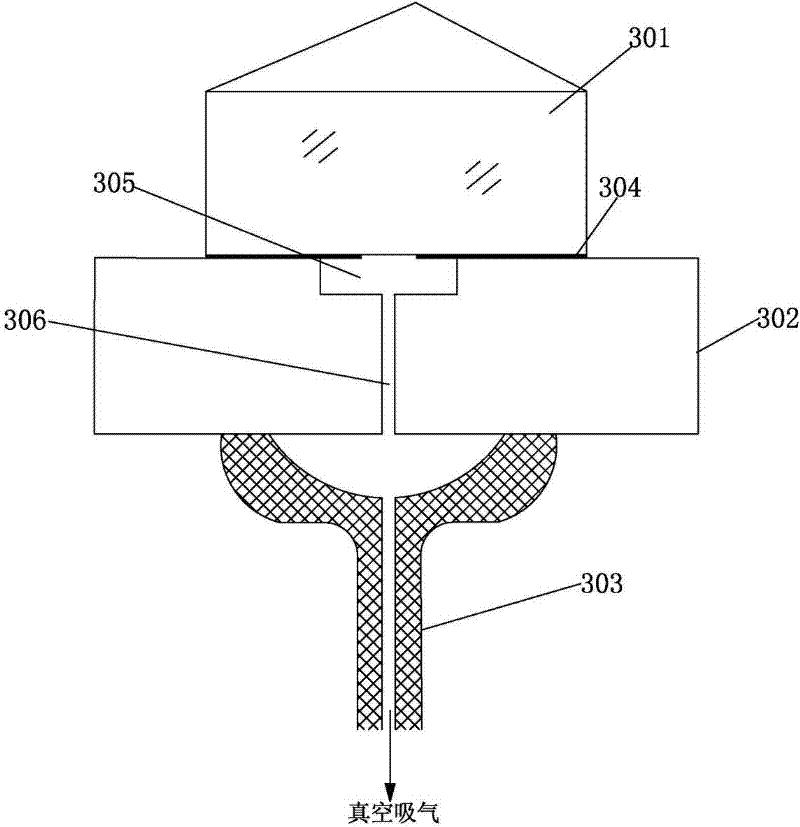

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] 301. Micro-optical components, 302. Connecting components, 303 . Exhaust pipe, 304. glue or solder, 305. cavity, 306. air hole.

[0013] Such as image 3 As shown, one or more cavities 305 smaller in size than the micro-optical element 301 are processed at the place where the connection element 302 will be bonded with the micro-optical element 301, and a corresponding air hole 306 is processed at the center of the cavity 305 of the connection element 302 , the cavity 305 and the vent hole 306 can be a combination of one or more pairs of arrays, and the specific bonding process is: apply glue or solder 304 around the position of the connection element 302 to be bonded, that is, the cavity 305, and then Put the micro-optical element 301 on the position where the connecting element 302 is to be bonded, turn on the vacuum pump, and the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com