Epoxy medium glue glass powder mica tape

A technology of glass powder and mica tape, which is applied in the direction of mica, quartz/glass/glass enamel, insulator, etc., can solve the problems of unreliable, low mica content, large insulation thickness, etc., and achieve good compatibility and wrapping coils Docile, good workmanship effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Preparation of adhesive

[0022] 20 parts of bisphenol A epoxy resin (brand name is E44), 10 parts of novolac epoxy resin (brand name is F44), 25 parts of bismaleimide tung oil anhydride, 5 parts of methyl tetrahydrophthalic anhydride, aluminum triacetylacetonate 0.3 parts, 20 parts of toluene, 20 parts of acetone. Mix together evenly and serve.

[0023] 2. Fabrication of mica tape

[0024] (1) Use two layers of non-alkali glass cloth for electricians (quantitatively 18g / m2), and glue the two sides of the glass cloth by dipping at room temperature;

[0025] (2) The quantitative will be 130g / m 2 506-D mica paper is laminated between two layers of glued glass cloth to obtain a three-in-one composite;

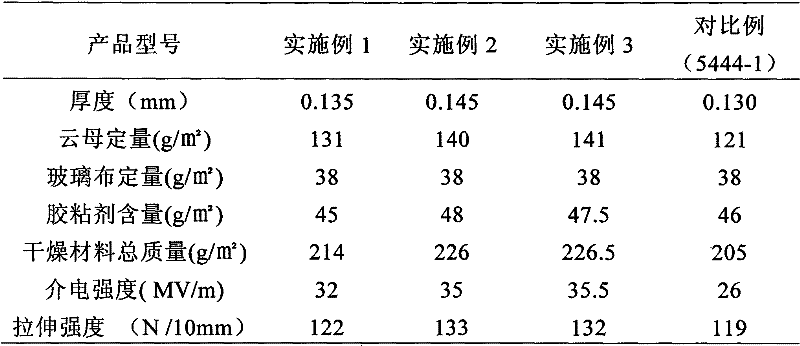

[0026] (3) Bake the obtained three-in-one compound at a temperature of 100-130°C for about 10 minutes, wind up and cut to obtain the epoxy medium-glue glass powder mica tape of this example. Its technical indicators are shown in Table 1.

Embodiment 2

[0028] 1. Preparation of adhesive

[0029] 19 parts of bisphenol A epoxy resin (brand name DER337), 11 parts of novolak epoxy resin (DER438), 25 parts of tung oil anhydride, 5 parts of methyl tetrahydrophthalic anhydride, 0.2 parts of aluminum triacetylacetonate, organic rare earth metal neodymium Nd 0.3 parts of salt, 20 parts of toluene, and 20 parts of acetone. Mix together evenly and serve.

[0030] 2. Fabrication of mica tape

[0031] (1) Use two layers of non-alkali glass cloth for electricians (quantitatively 18g / m2), and glue the two sides of the glass cloth by dipping at room temperature;

[0032] (2) The quantitative will be 140g / m 2 507 mica paper is pasted between two layers of glued glass cloth to obtain a three-in-one composite;

[0033] (3) Bake the obtained three-in-one compound at a temperature of 100-130°C for about 10 minutes, wind up and cut to obtain the epoxy medium-glue glass powder mica tape of this example. Its technical indicators are shown in Ta...

Embodiment 3

[0035] 1. Preparation of adhesive

[0036] 16 parts of bisphenol F epoxy resin (brand is YDF170), 4 parts of bisphenol A epoxy resin (brand is EP1001), 10 parts of novolak epoxy resin (brand is DER431), alicyclic epoxy resin (brand is DER431) 2 parts of ERRA4211), 25 parts of bismaleimide tung oil anhydride, 5 parts of methyl hexahydrophthalic anhydride, 0.1 part of aluminum triethylacetoacetate, 0.4 parts of organic rare earth metal neodymium Nd salt, 20 parts of toluene, 20 parts of acetone . Mix together evenly and serve.

[0037] 2. Fabrication of mica tape

[0038] (1), use two layers of electrician's non-alkali glass cloth (quantitatively 18g / m2), adopt the mode of dipping glue to glue the both sides of glass cloth at normal temperature;

[0039] (2) Paste the 140g / m2507 mica paper paper between the two layers of glued glass cloth to obtain a three-in-one compound;

[0040] (3) Bake the obtained three-in-one compound at a temperature of 100-130° C. for about 5-10 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com