Communication equipment, cavity filter, resonant rod and manufacturing method thereof

A technology of cavity filter and manufacturing method, which is applied in the field of communication, can solve problems such as high cost, and achieve the effects of low cost, improved equipment performance index, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

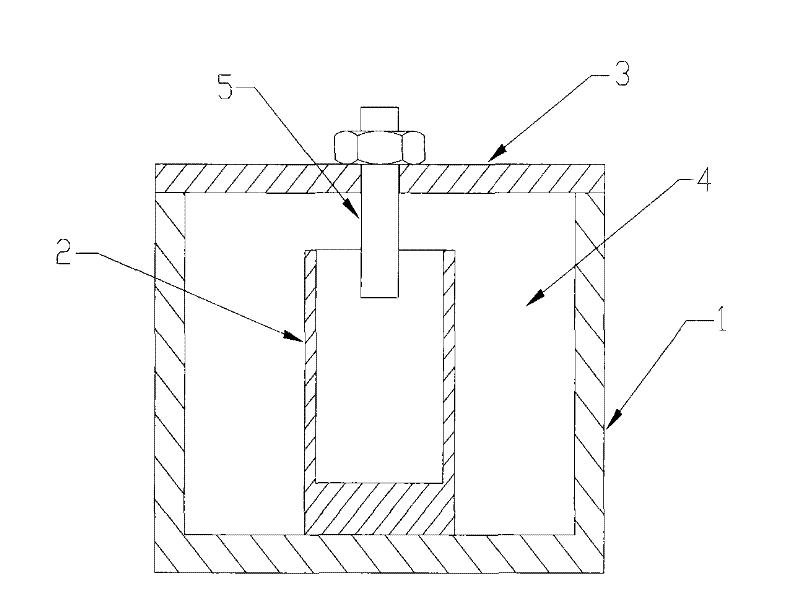

[0019] See figure 1 , figure 1 is a partial structural schematic diagram of the cavity filter 1 including the resonant rod 2 according to the first embodiment of the present invention.

[0020] like figure 1 As shown, in simple terms, the cavity filter mainly includes a cavity 1 , a resonant rod 2 and a cover plate 3 . Of course, the cavity filter of this embodiment also includes various other conventional components or structures. Here, this embodiment only describes the parts related to the invention points of this embodiment. For other specific components or structures, you can refer to the existing The conventional implementation mode does not constitute a limitation to the present invention.

[0021] In this embodiment, the cavity 1 is made of metal material, and its shape can be a square columnar cavity, a circular columnar cavity or a polygonal columnar cavity. The cover plate 3 covers the cavity 1 . The cavity 1 is covered with the cover plate 3 to form a resonant...

Embodiment 2

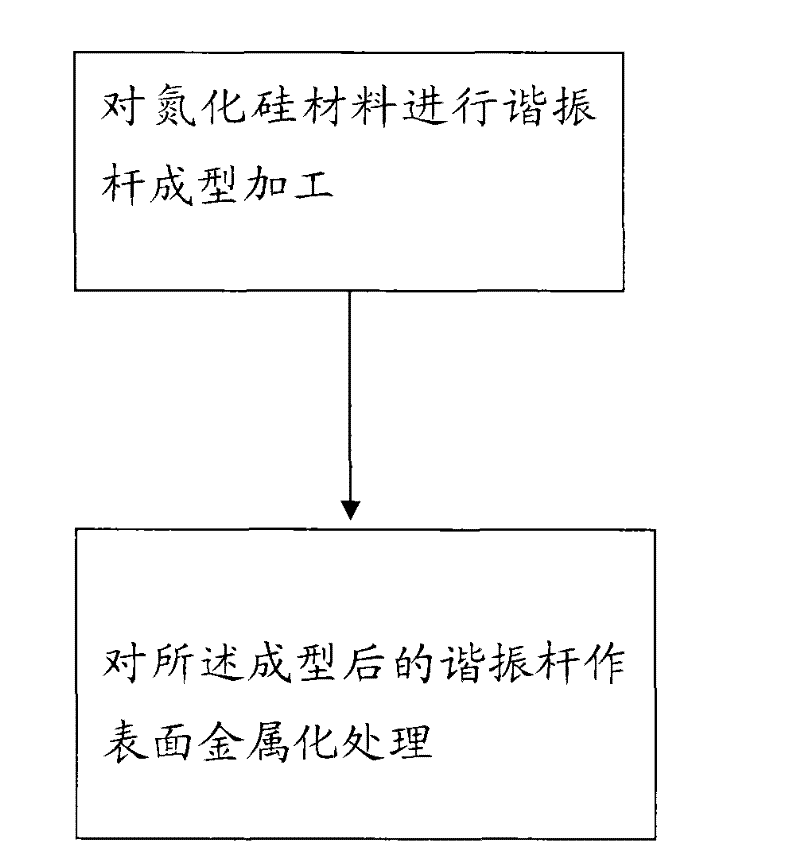

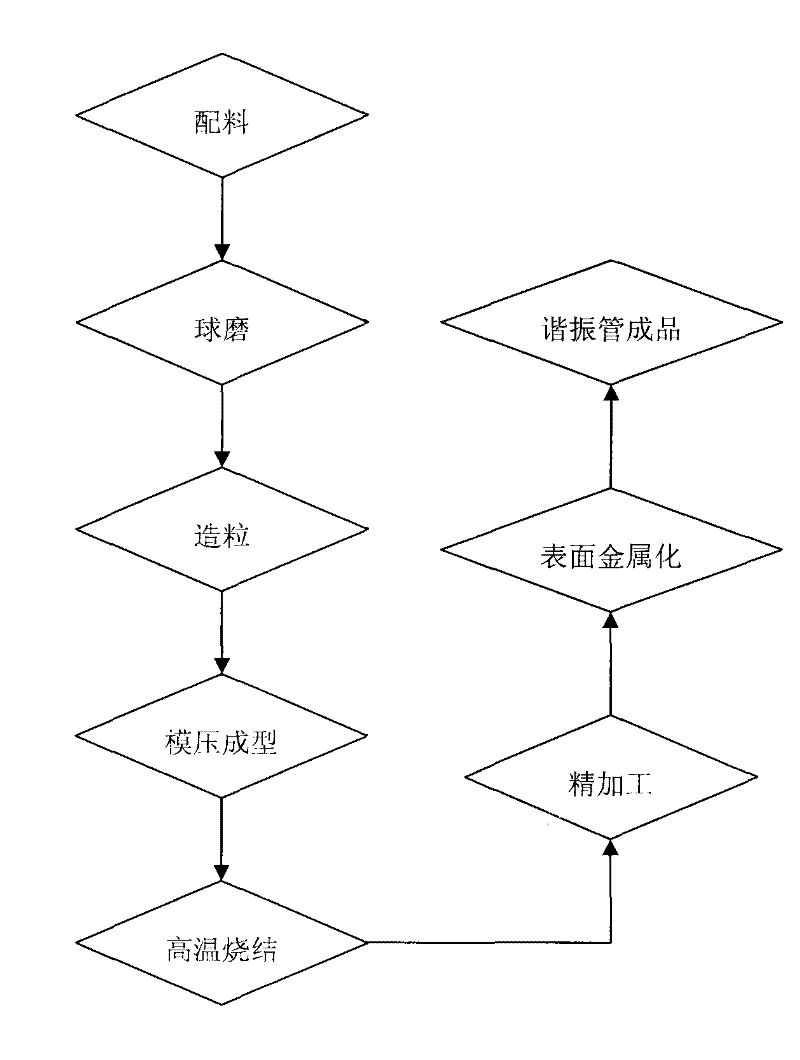

[0029] A kind of manufacturing method of resonant rod, please refer to figure 2 and image 3 , image 3 It is a simplified flowchart of a manufacturing method of the resonant rod 2 according to an embodiment of the present invention.

[0030] The general manufacturing process of the resonant rod 2 consists of two steps:

[0031] Forming and processing of resonant rods on silicon nitride materials;

[0032] Perform surface metallization treatment on the formed resonant rod.

[0033] Wherein, the process of forming the resonator rod on the silicon nitride material further includes the following steps: batching silicon nitride powder or granules as raw materials; ball milling the silicon nitride powder or granules with a ball mill to make the nitride Silicon powder or granule crushing; in order to facilitate sintering, it is usually desired to obtain ultra-fine raw material particles, but the finer the powder, the larger the specific surface area, the poorer the fluidity, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com