Manufacturing method of drinking straw and drinking straw implementing the method

A manufacturing method and technology of straws, applied in the field of beverage straw manufacturing and beverage straws, can solve the problems of low playability and interest, failure to meet individual needs, lack of fun, etc. Low, playful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

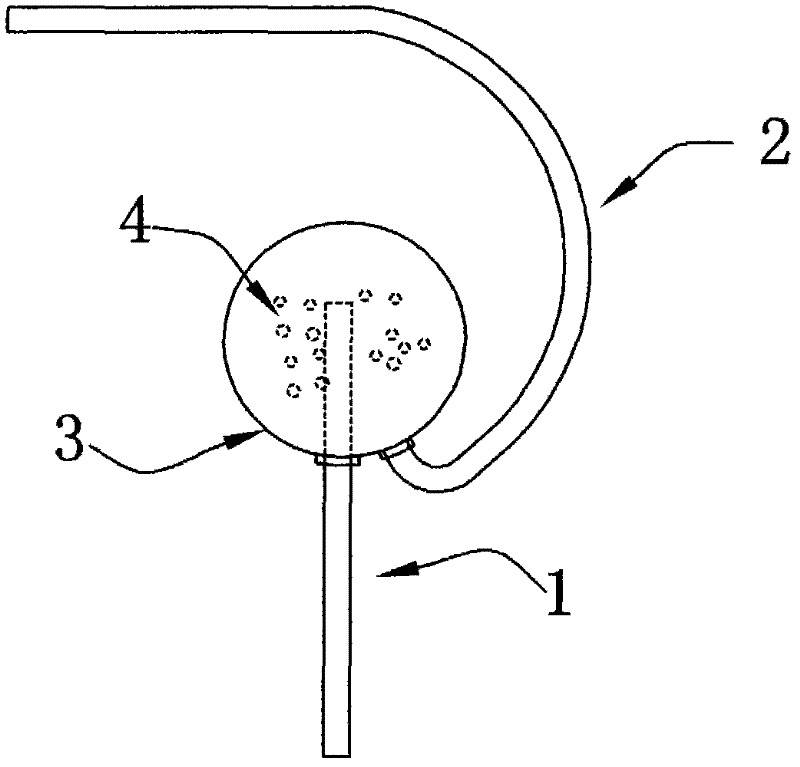

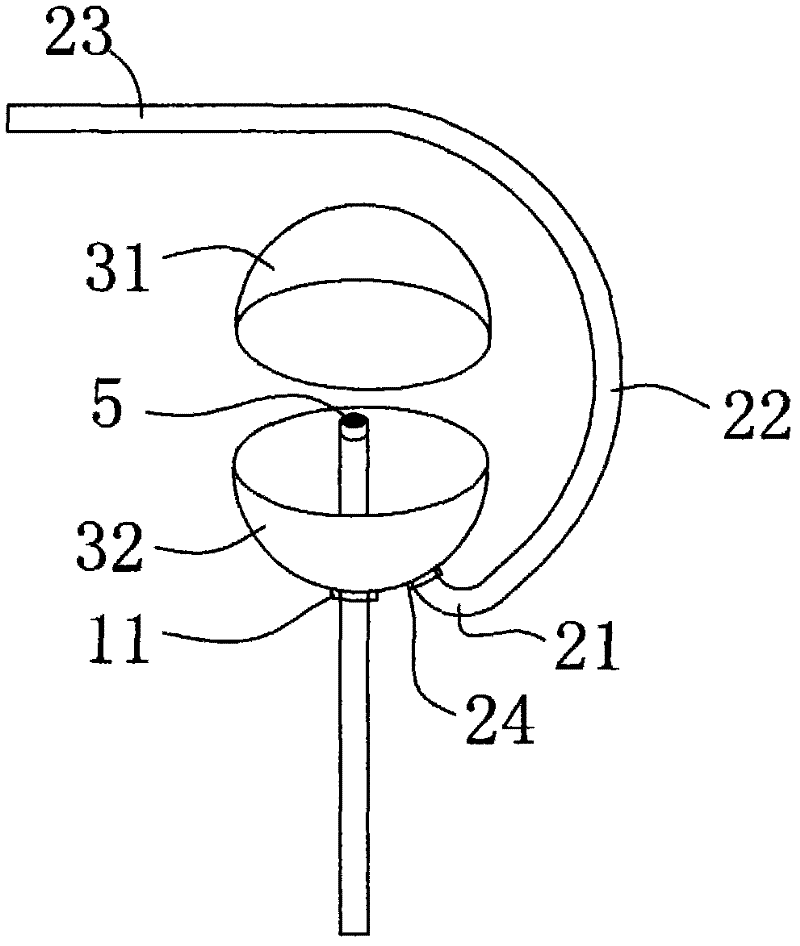

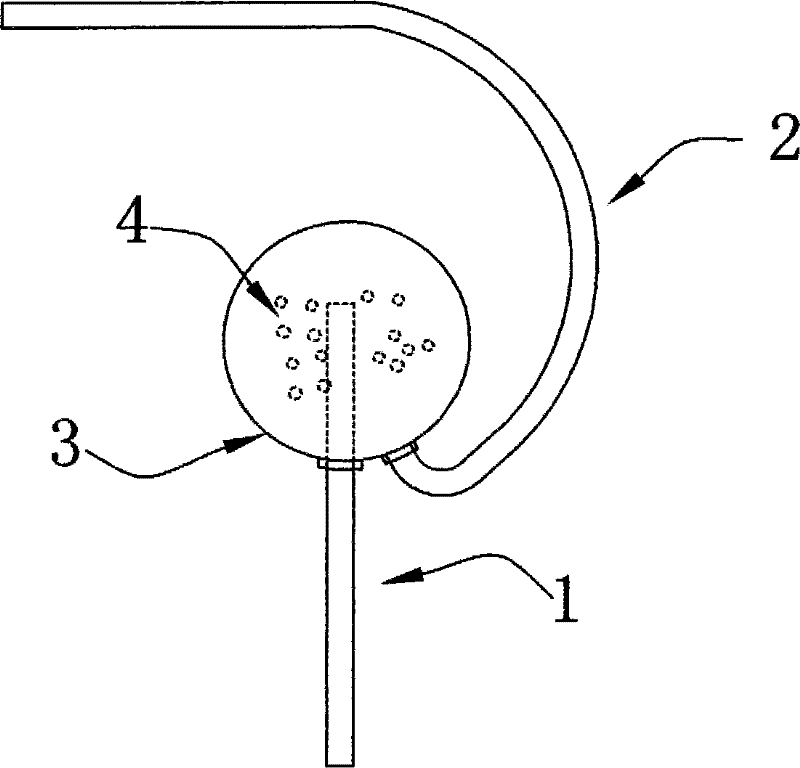

[0033] Example: see figure 1 and figure 2 , the present embodiment provides a drinking straw manufacturing method, which includes the following steps:

[0034] (1) Manufacture of straws: prepare the straw extruder, extrude and form the first straw body 1 and the second straw body 2;

[0035] (2) Manufacture the shell: prepare the injection molding machine, and injection mold a transparent or translucent shell 3 with an internal cavity;

[0036] (3) Manufacturing floating particles: preparing injection molding materials of various colors, and molding a plurality of floating particles 4 of different colors by injection molding machine;

[0037] (4) Assembling: put the floating particles 4 into the inner cavity of the housing 3, fix the head of the first straw body 1 on the bottom center of the housing 3, and make the first straw The pipeline of the body 1 communicates with the inner cavity of the housing 3, and the second straw body 2 is fixed on the bottom of the housing 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com