Flow characteristic testing device of nozzle of gas fire-extinguishing system

A technology for fire-extinguishing system and flow characteristics, which is applied in the field of testing devices for nozzle flow characteristics of gas fire-extinguishing systems, can solve problems such as the influence of measurement data accuracy, dynamic instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

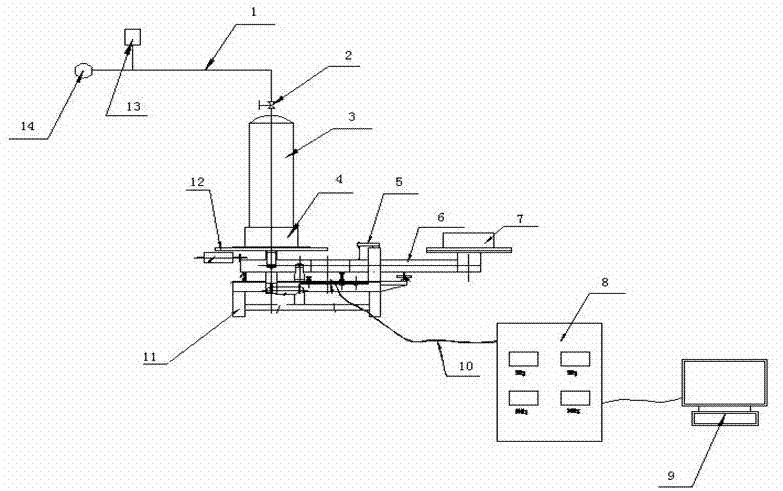

[0016] Such as figure 1 As shown, the gas fire extinguishing system nozzle flow characteristic testing device includes three parts: a weighing device, a pressure measuring device, and a data acquisition and processing system. composition,

[0017] The base 11 is mainly used to support the weighing platform 12, the balance platform 7 and the lever 6. The base 11 is provided with a lever fulcrum, and the lever 6 is supported by the lever fulcrum. The lever 6 is divided into two parts by the fulcrum, and the two ends of the lever 6 are fixed respectively. Heavy platform 12 and balance platform 7, one end of lever 6 is weighing platform 12, and the other end is balance platform 7,

[0018] The force arm of the lever 6 is designed as an unequal arm structure, with the fulcrum as the origin, the ratio of the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com