High-speed component distributing device

A technology of distributing devices and components, applied in sorting and other directions, can solve the problems of limited distributing speed, reduced reliability, and static electricity, and achieve the effect of reducing load inertia, reducing power requirements, and eliminating static electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

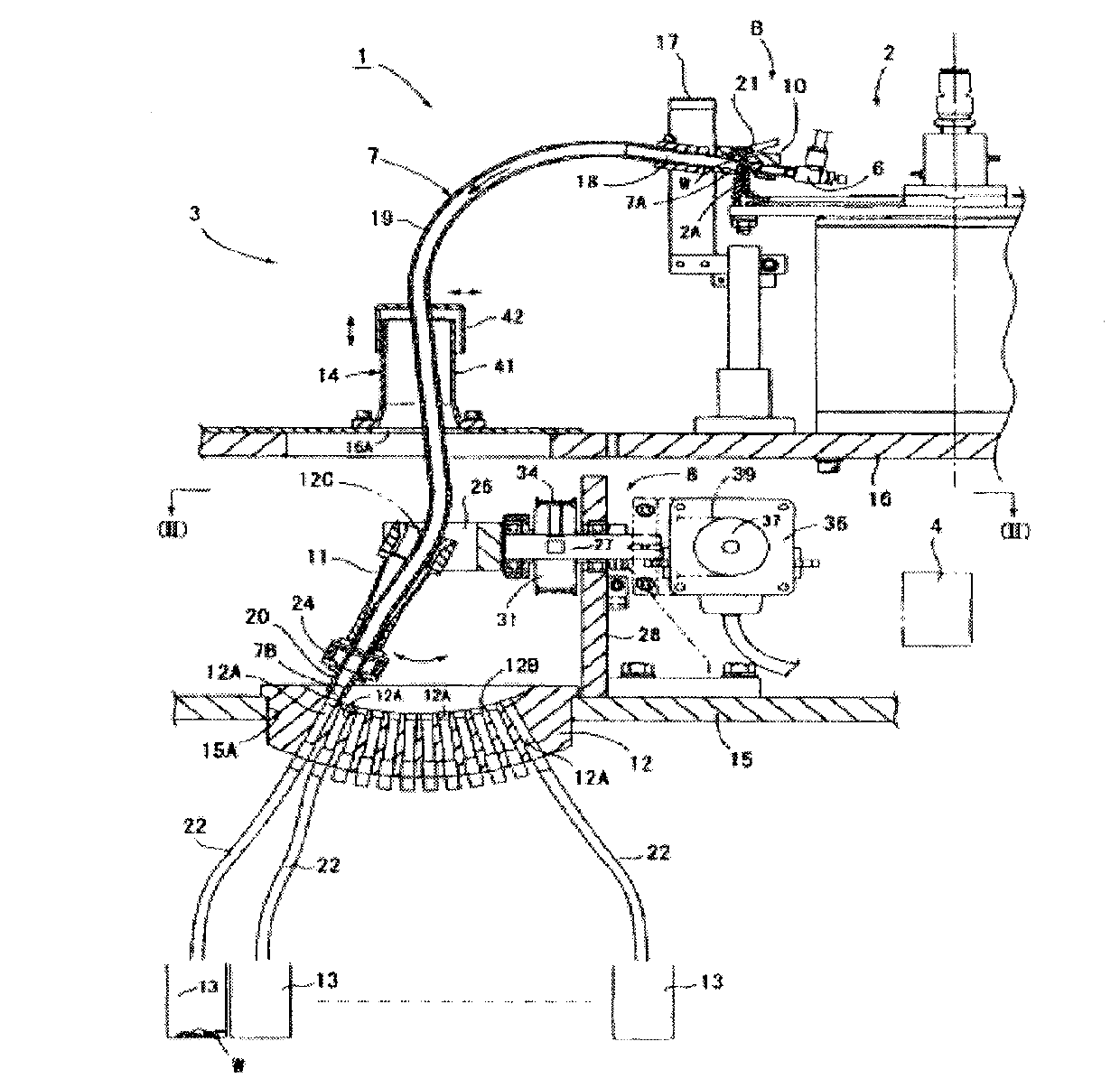

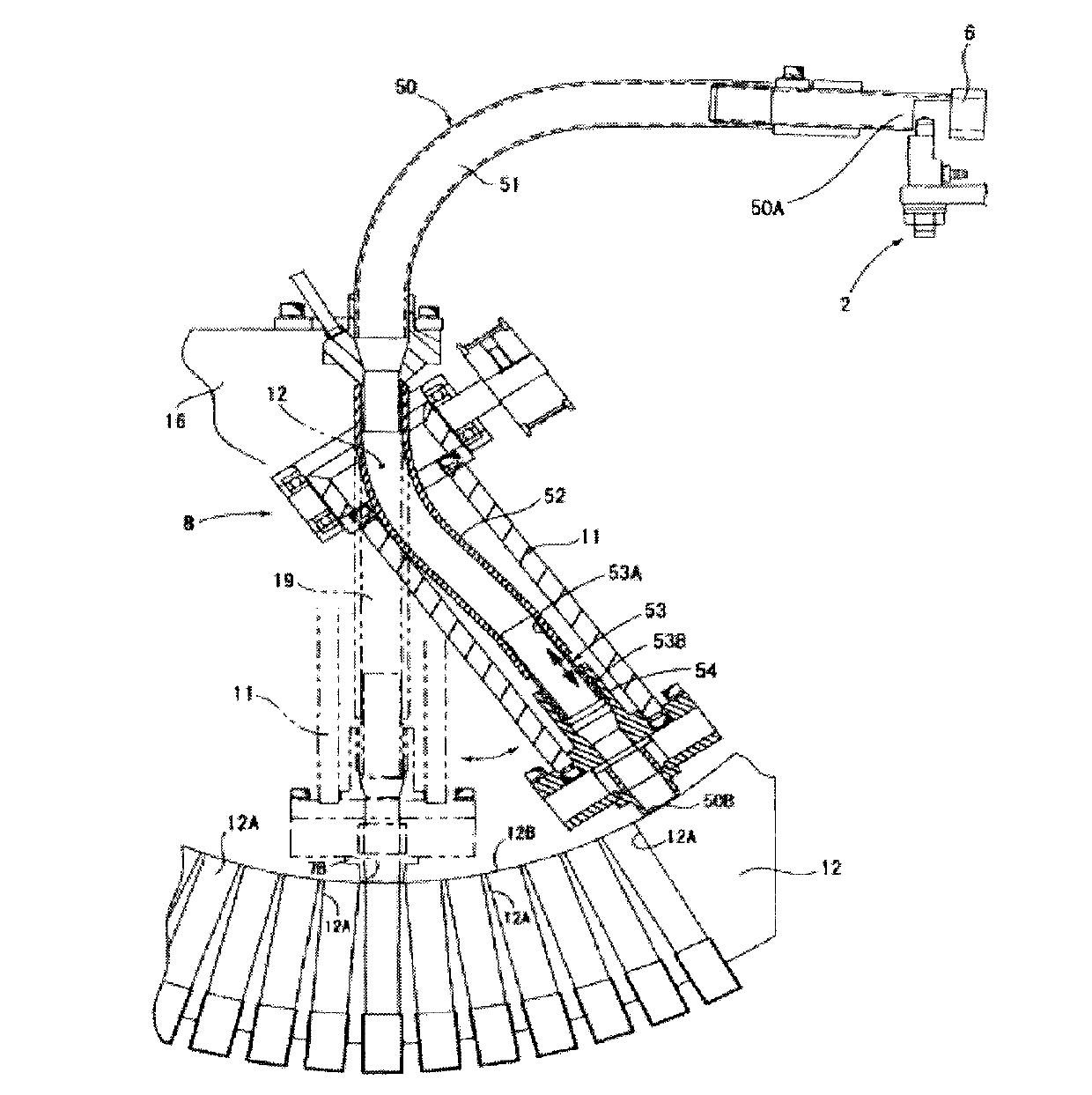

[0026] see Figure 5 , the component high-speed distributing device of the present invention comprises: servo motor one 1, servo motor two 8, wherein said servo motor one 1 connects bearing seat one 10 through connection block one 3, controls bearing seat one 10 movement; Servo motor two 8 is connected to bearing seat 2 20 through connecting block 2 9 to control the movement of bearing seat 2 20; servo motor 1 and servo motor 2 8 are both installed on the base 21, and both are vertically distributed, and servo motor 1 and servo motor The plane formed by the axis of the second 8 is parallel to the horizontal plane; the first bearing housing 10 and the second bearing housing 20 are provided with a crossed roller bearing 12 and a crossed roller bearing 2 18, and the inner rings of the two crossed roller bearings are respectively Swing arm 1 17 and swing arm 2 13 are installed, and swing arm 1 17 and swing arm 2 13 are connected through a deep groove ball bearing 30 to form a coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com