A kind of sheet forming die and sheet forming method

A thin plate forming and mold technology, applied in the field of plastic processing, can solve the problems of large mold volume, no watermark, expensive products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

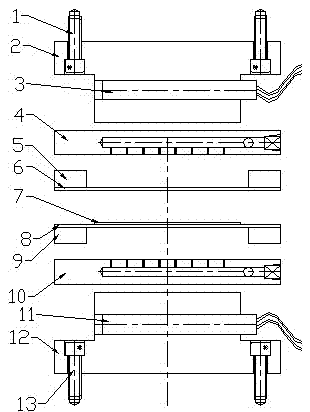

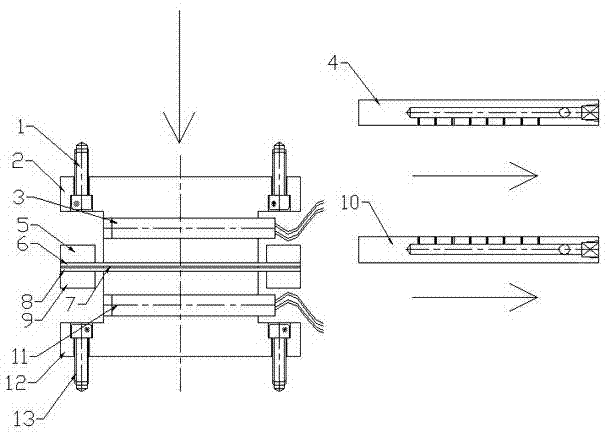

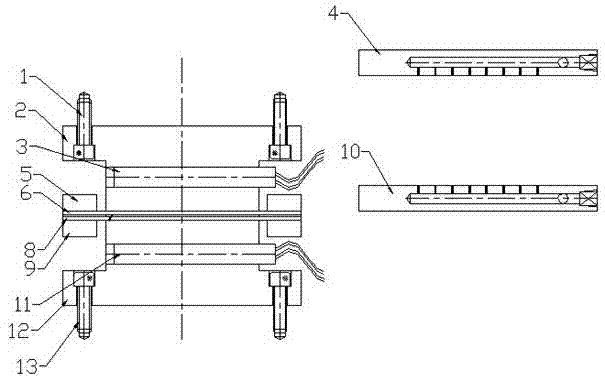

[0023] The thin plate forming mold includes the upper positioning wire 1, the upper heating platen 2, the upper heating pipe 3, the upper blowing heat insulation plate 4, the upper pattern plate suspension frame 5, the upper ultra-thin pattern plate 6, the plastic plate 7, and the lower ultra-thin pattern Plate 8, lower checkered plate suspension frame 9, lower air blowing insulation board 10, lower heating pipe 11, lower heating pressing plate 12, lower positioning thread 13;

[0024] The upper heating platen 2 is fixedly connected with the upper template through the upper positioning wire 1, and the lower heating platen 12 is fixedly connected with the lower template through the lower positioning wire 13, so as to transmit heat and press the softened rubber sheet to form; The heat pipe 3 and the lower heating platen 12 are provided with the lower heating pipe 11 to provide thermal softening rubber sheet molding; the upper blowing heat shield 4 and the lower blowing heat shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com