Unloading valve with cooling and automatic drain

A technology of automatic sewage discharge and sewage discharge device, which is applied in the direction of valve heating/cooling device, valve device, transportation and packaging, etc. It can solve problems such as unreasonable, complex structure of cooling device, and incomplete closure of sewage outlet, so as to ensure sewage discharge effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

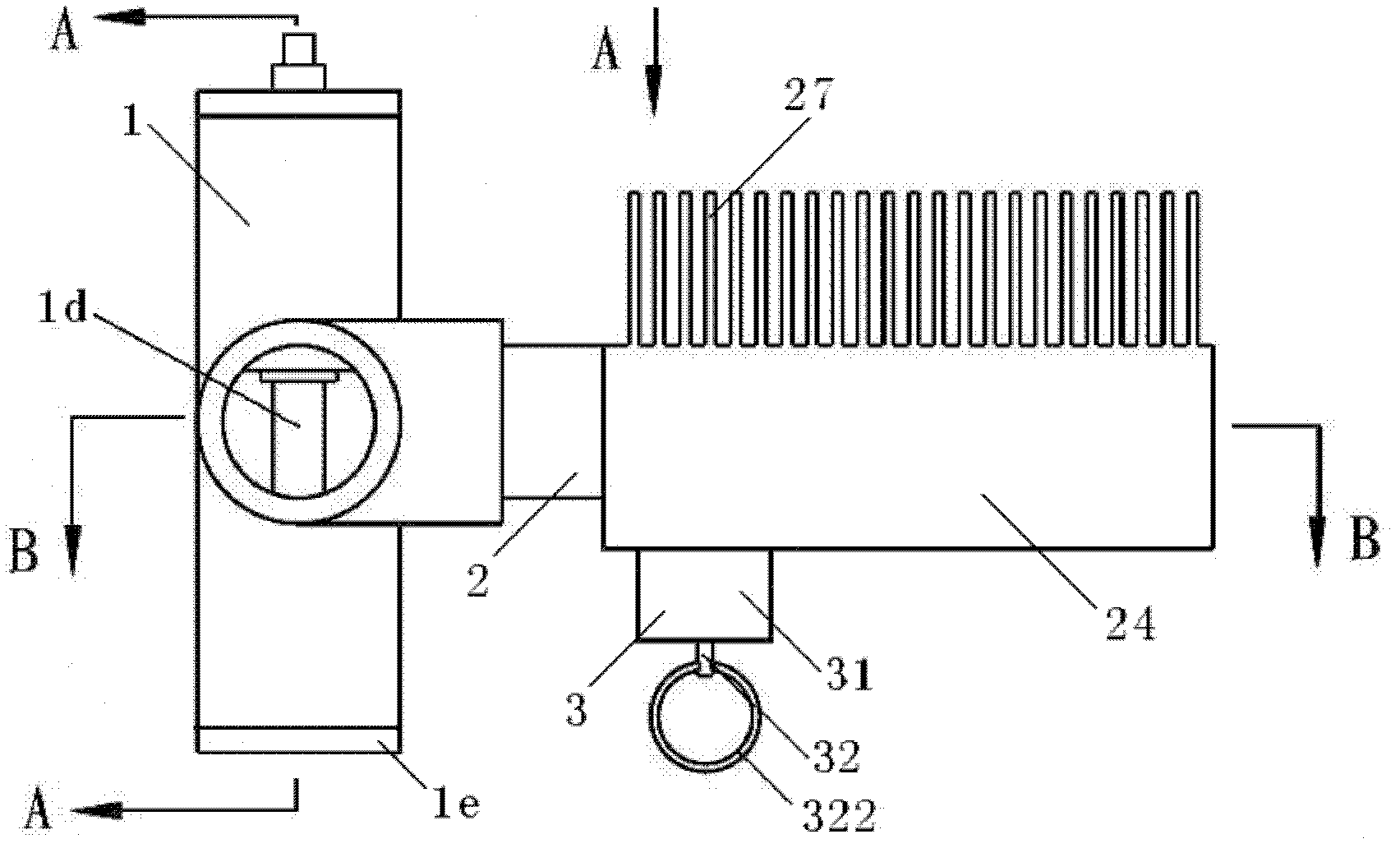

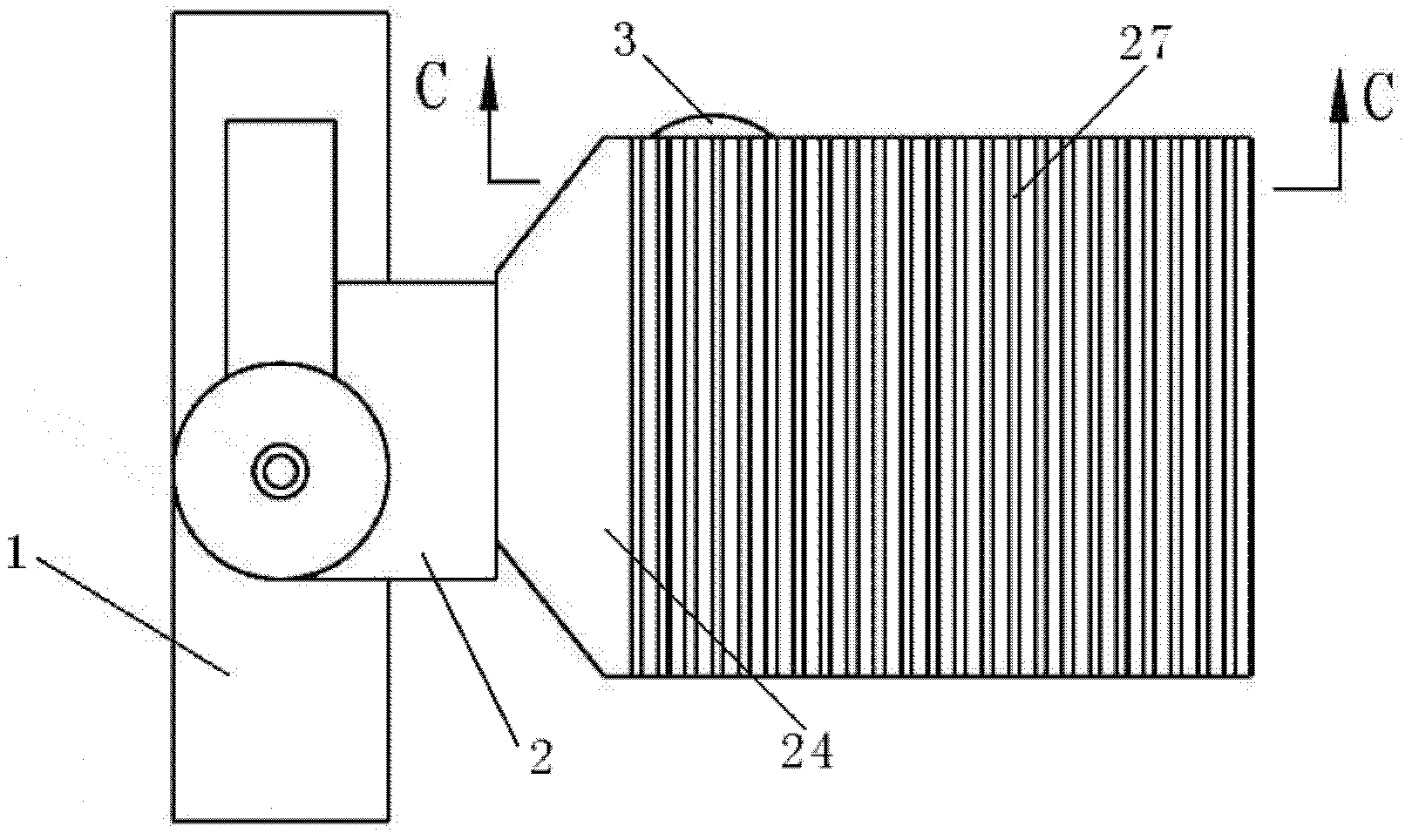

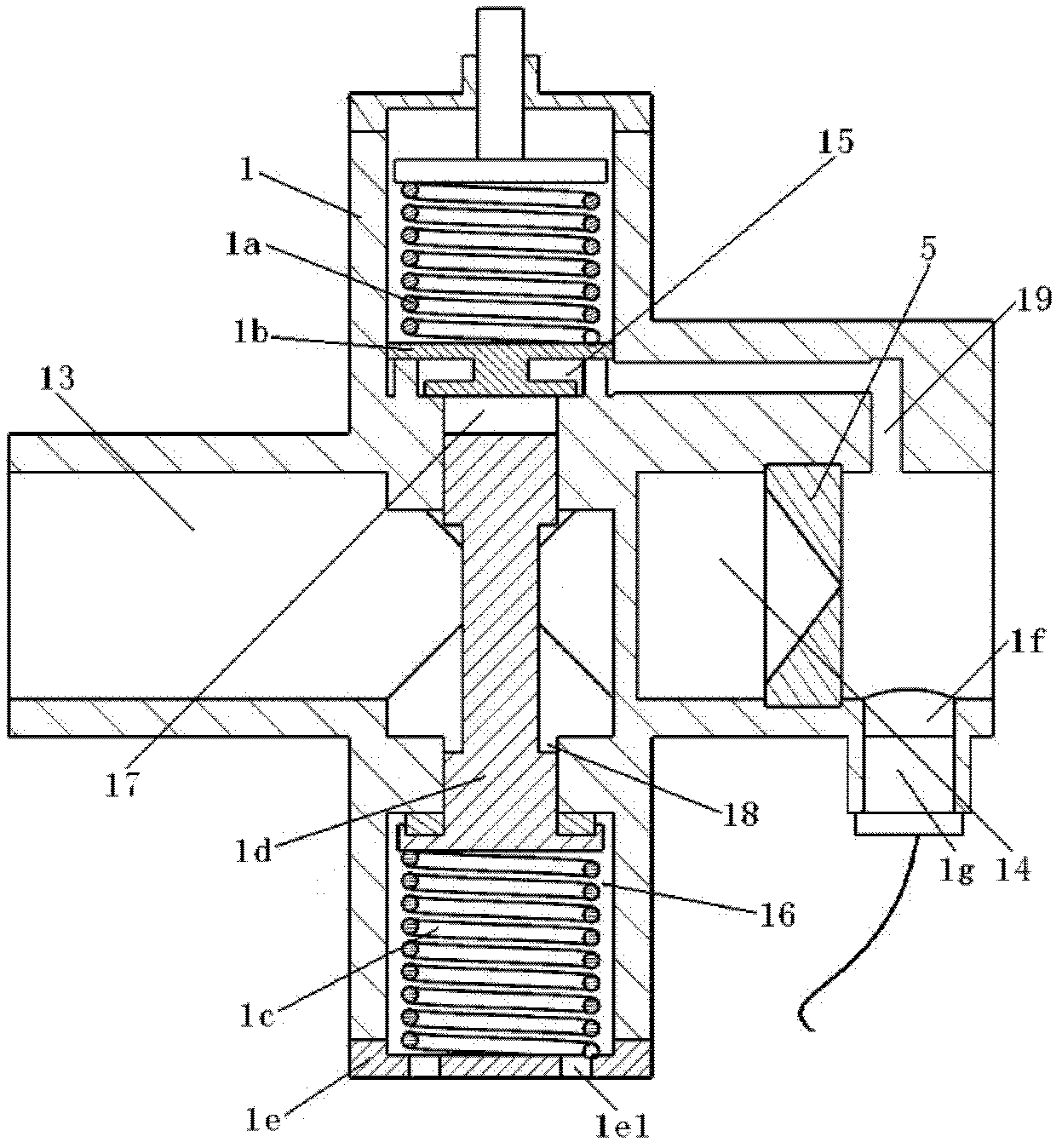

[0021] Embodiment: The present invention includes a valve body 1 , a cooling device 2 , a sewage discharge device 3 , an air intake check valve 4 and an air outlet check valve 5 .

[0022] Described valve body 1 is provided with inlet passage outlet 11, outlet passage inlet 12, inlet passage 13, outlet passage 14, upper gas passage 15, lower gas passage 16, two ends are connected with inlet passage 13 and upper gas passage 15 respectively. The first communication air channel 17 communicated, the second communication air channel 18 whose two ends are respectively communicated with the intake channel 13 and the lower gas channel 16, and the third communication air channel whose two ends are respectively communicated with the air outlet channel 14 and the upper gas channel 15 19 and the pressure measuring port 1f of the outlet channel, which also includes an upper spring 1a and an upper piston 1b located in the upper gas channel 15, and a lower piston with one end passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com