A fully automatic tube loading machine used in conjunction with a bottle making machine

A bottle making machine, fully automatic technology, applied in the direction of manufacturing tools, glass forming, glass reshaping, etc., can solve the problems of time-consuming, low efficiency, low degree of automation, etc., to reduce labor intensity and high reliability , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

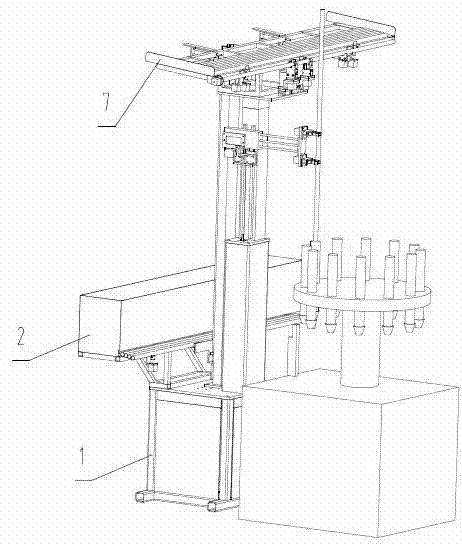

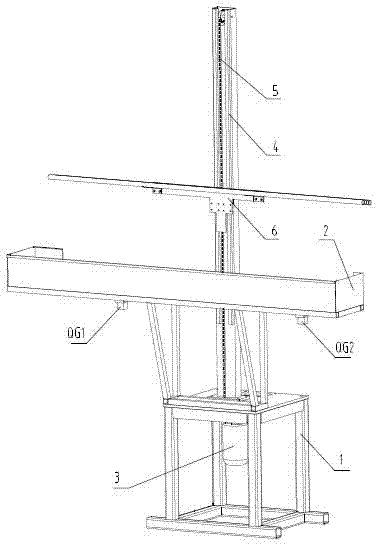

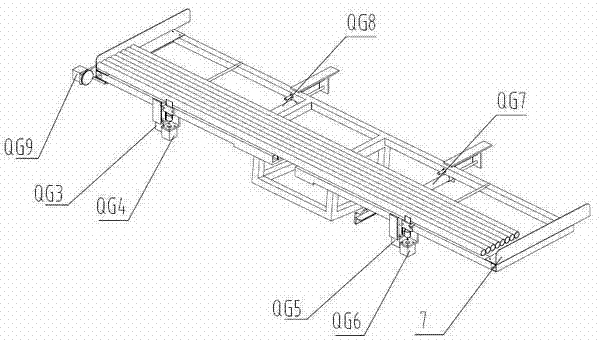

[0014] Such as figure 1 As shown, the fully automatic tube loading machine is mainly composed of a detector, a controller, a tube feeding and lifting mechanism, a tube feeding mechanism, a tube grasping steering mechanism and an intubation mechanism. The detection points of the detector are respectively set on the tube feeding and lifting mechanism , the tube feeding mechanism, the tube grabbing steering mechanism, the tube intubation mechanism and the corresponding positions of the bottle making machine. The tube mechanism, the tube grasping steering mechanism and the control end of the controlled part of the intubation mechanism are connected; The mechanism is assembled on the top of the support column 1 on one side of the corresponding pipe delivery mechanism, and the intubation mechanism is fixed on the bottom of the support column 1 corresponding to the position of the bottle making machine chuck and the pipe grabbing steering mechanism. The composition and connection re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com