Growth system and method of crystalline hafnium

A technology of crystallization and reactor, which is applied in the field of crystalline hafnium growth system, can solve the problems of restricting the use area, reducing the growth speed, and low efficiency, and achieve the effects of reducing the use of accessories and consumables, accelerating the growth speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

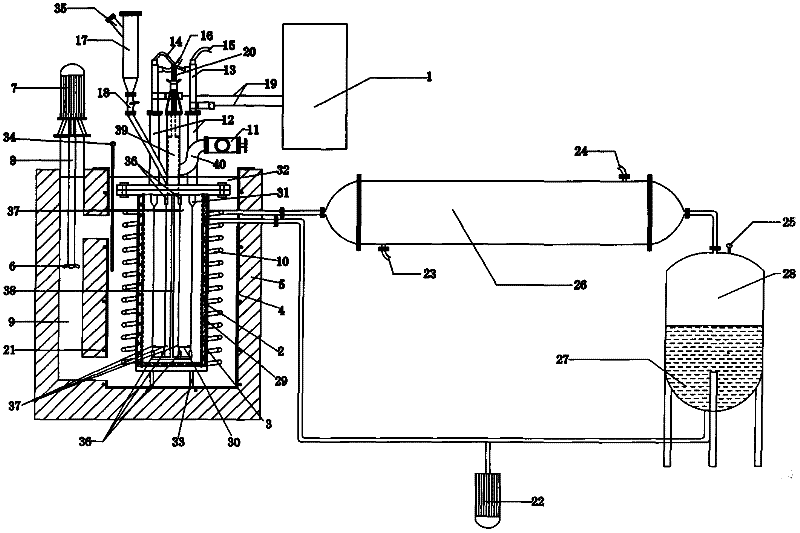

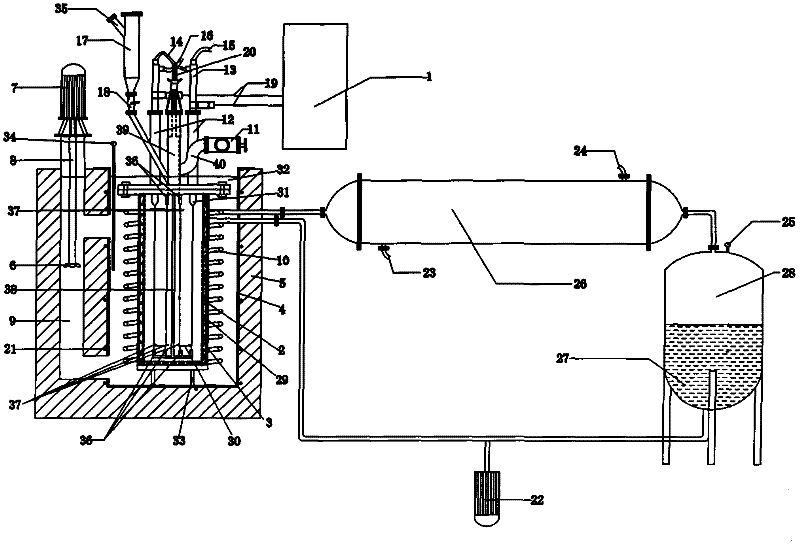

[0028] Example: Reference figure 1 , the present invention provides an embodiment of a growth system for crystalline hafnium, which includes a power supply unit 1, a reactor 2, a molybdenum shield 3 arranged in the reactor 2, a salt bath furnace 4, and a cooling device for cooling the reactor 2. A cooling unit, a vacuum unit (not shown) for vacuuming the reactor 2, an iodine box 17 controlled by a ball valve 18 for adding iodine to the reactor 2, an electrode unit, and a crystallization unit.

[0029] Power supply unit 1, the voltage of which is steplessly adjustable within the range of 1.0V-180V, and the maximum designed output current is 1400A.

[0030] Reactor 2 is made of 316L stainless steel, with an inner diameter of 420mm and a clear height of 1100mm, and can be put into the salt bath furnace 4 as a whole. There is a bracket 38 for hanging the mother wire 30 in the reactor 2, and an insulating electrical ceramic sheet 36 is fixed on the bracket, and a molybdenum wire 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com