Washing machine outer tub parts and automatic washing machine

A technology for washing machines and components, applied in the field of fully automatic pulsator washing machines, which can solve the problems of not being able to clean the inner wall of the outer tub or the outer wall of the inner tub of the washing machine, plastic particles cannot be smoothly floated out of the drain valve, etc., so as to avoid secondary pollution and solve worries for the future , solve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The outer tub part of the washing machine and the fully automatic washing machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

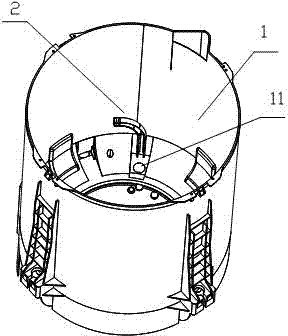

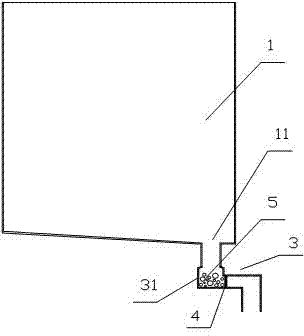

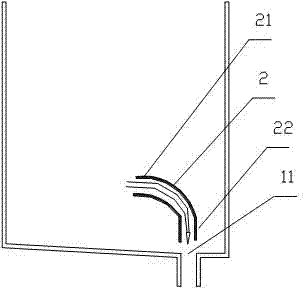

[0024] see figure 1 , an embodiment of the outer tub part of the washing machine according to the present invention includes an outer tub 1, an installation hole for installing a reducer at the bottom of the outer tub, an outer tub drain port 11, a drainage control system, and a drain valve 3, and the outer tub wall is provided with The curved diversion groove 2, the horizontal water inlet end 21 is arranged at 1 / 3-1 / 2 of the height of the outer tub wall, preferably, the position of the arc diversion groove 2 water inlet end 21 is located near the low water level of the washing machine, so as to guide When the launder should be able to meet the minimum water level, water can still be collected, and the vertical water outlet end 22 is arranged directly above the outer barrel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com