An inflatable multi-stage water bag loading test pile method and its device

An inflatable, water bladder technology, applied in basic structure testing, construction, infrastructure engineering and other directions, can solve the problems of long loading and unloading time, high transportation cost, and difficulty for transport vehicles to enter the field, and achieves overcoming the high transportation costs, Simple equipment, simple calculation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

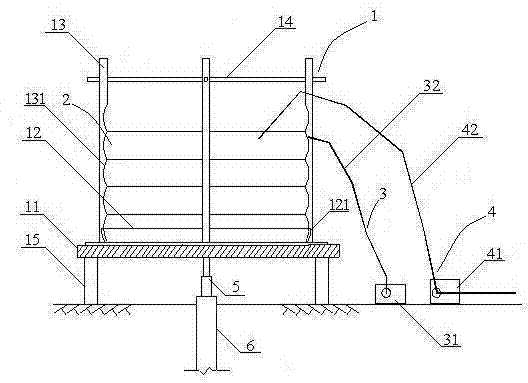

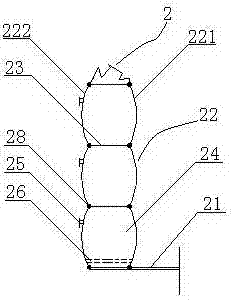

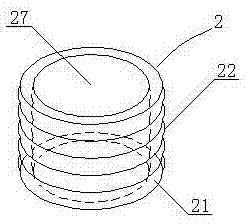

[0031] Such as figure 1 As shown, an inflatable multi-stage water bag loading pile test device in this embodiment includes a support device 1, a multi-stage water bag 2, a water bag inflation system 3 and a water bag water injection system 4, wherein:

[0032] The support device 1 is installed above the jack 5, the jack 5 is installed on the pile 6 to be tested, the support device 1 is used to install the multi-stage water bag 2, the support device 1 is a hollow cavity with an upper opening, and the bottom of the support device 1 is installed on the jack 5, the multi-stage water bag 2 is placed in the hollow cavity of the support device 1, and the inner diameter of the cavity of the support device 1 is slightly greater than or equal to the outer diameter of the inflated multi-stage water bag 2 to provide stability for the multi-stage water bag 2. support.

[0033] exist figure 1 In the embodiment of the present invention, the supporting device 1 includes a spacer 15, a steel...

Embodiment 2

[0042] A kind of inflatable multi-stage water bag loading test pile device of the present embodiment, its loading test pile method comprises the following steps:

[0043] The first step is to install the supporting device 1, install the steel beam 11 above the jack 5, install the steel base plate 12 and the vertical enclosure guide frame 13 on the steel beam 11, and install the steel beam 11, the steel base plate 12 and the vertical enclosure The guide frames 13 are connected by bolts, and the two section steels forming the top cross support 13 are fixed by bolts, and the top cross support 14 and the four vertical enclosure guide frames 13 are respectively fixed by bolts; the steel bottom plate 12, the vertical The enclosure guide frame 13 and the top cross support 14 form a hollow cavity with an upper opening;

[0044] In the second step, the uninflated multi-stage water bladder 2 is placed in the hollow cavity assembled in the first step;

[0045] In the third step, through...

Embodiment 3

[0051] A kind of inflatable multi-stage water bag loading test pile device of the present embodiment, its loading test pile method comprises the following steps:

[0052] The first step is to install the supporting device 1, install the steel beam 11 above the jack 5, install the steel base plate 12 and the vertical enclosure guide frame 13 on the steel beam 11, and install the steel beam 11, the steel base plate 12 and the vertical enclosure The guide frames 13 are connected by bolts, and the two section steels forming the top cross support 14 are fixed by bolts, and the top cross support 14 and the four vertical enclosure guide frames 13 are respectively fixed by bolts; the steel bottom plate 12, the vertical The enclosure guide frame 13 and the top cross support 14 form a hollow cavity with an upper opening;

[0053] In the second step, the uninflated multi-stage water bladder 2 is placed in the hollow cavity assembled in the first step;

[0054] In the third step, through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com