Automatic defrosting control method for frost-free refrigerator

A control method and refrigerator technology, applied in defrosting, household refrigerators, household refrigeration devices, etc., can solve the problems of wasting electric energy, affecting the freshness preservation function of refrigerators, and unable to detect the heat exchange performance of refrigerator evaporators in real time, so as to reduce energy consumption. consumption, improve the quality of food preservation, and withdraw from the effect in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

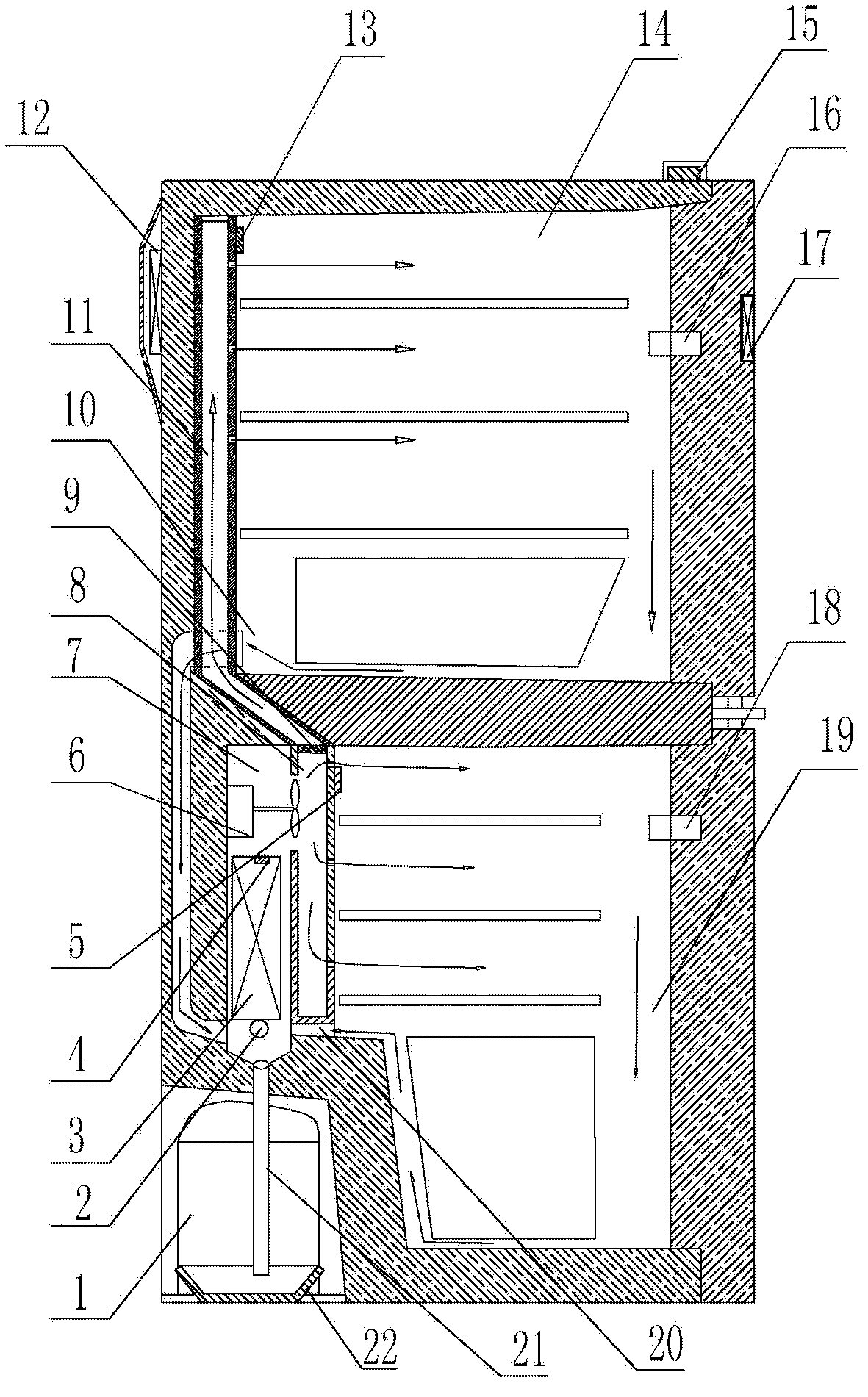

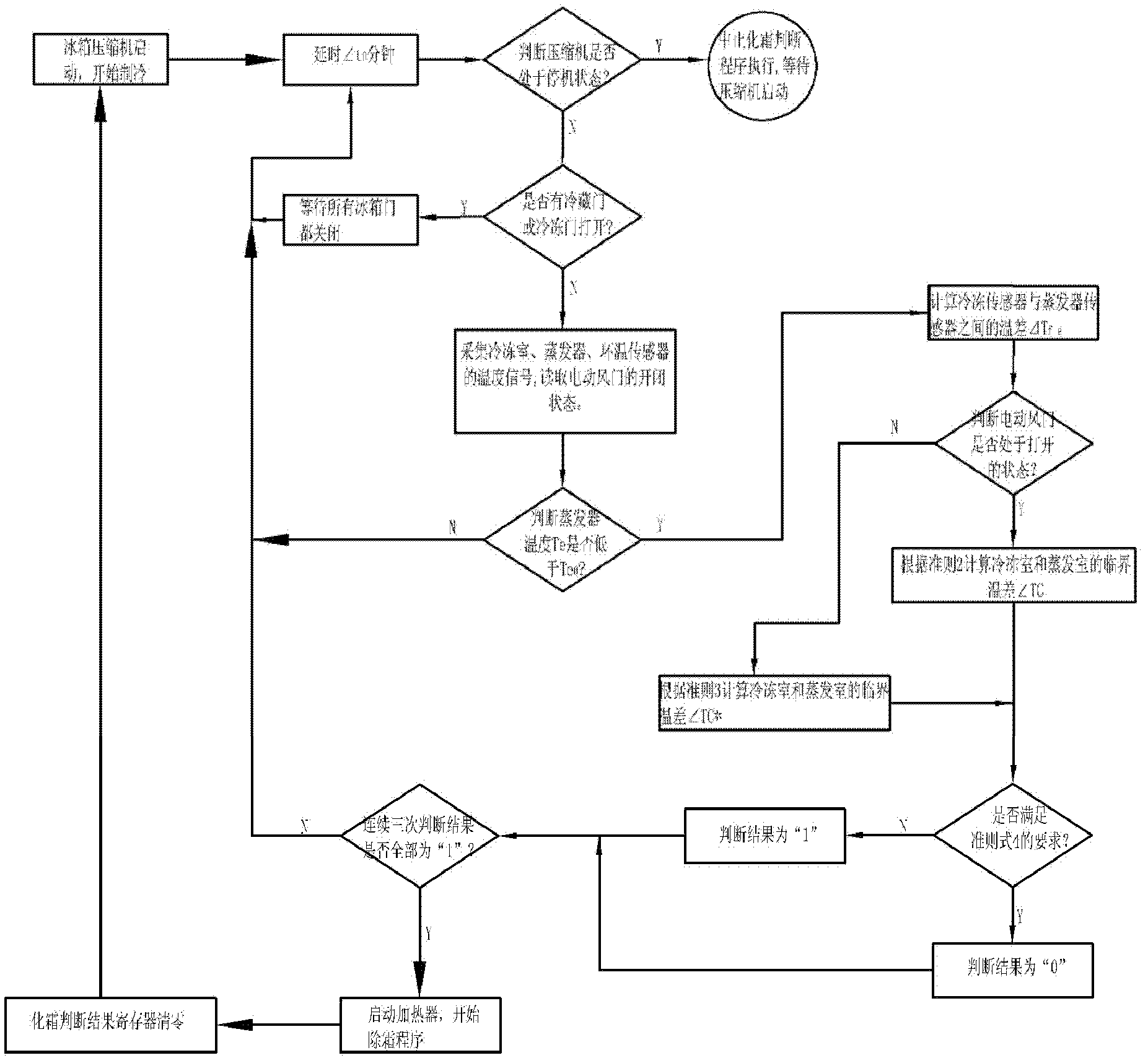

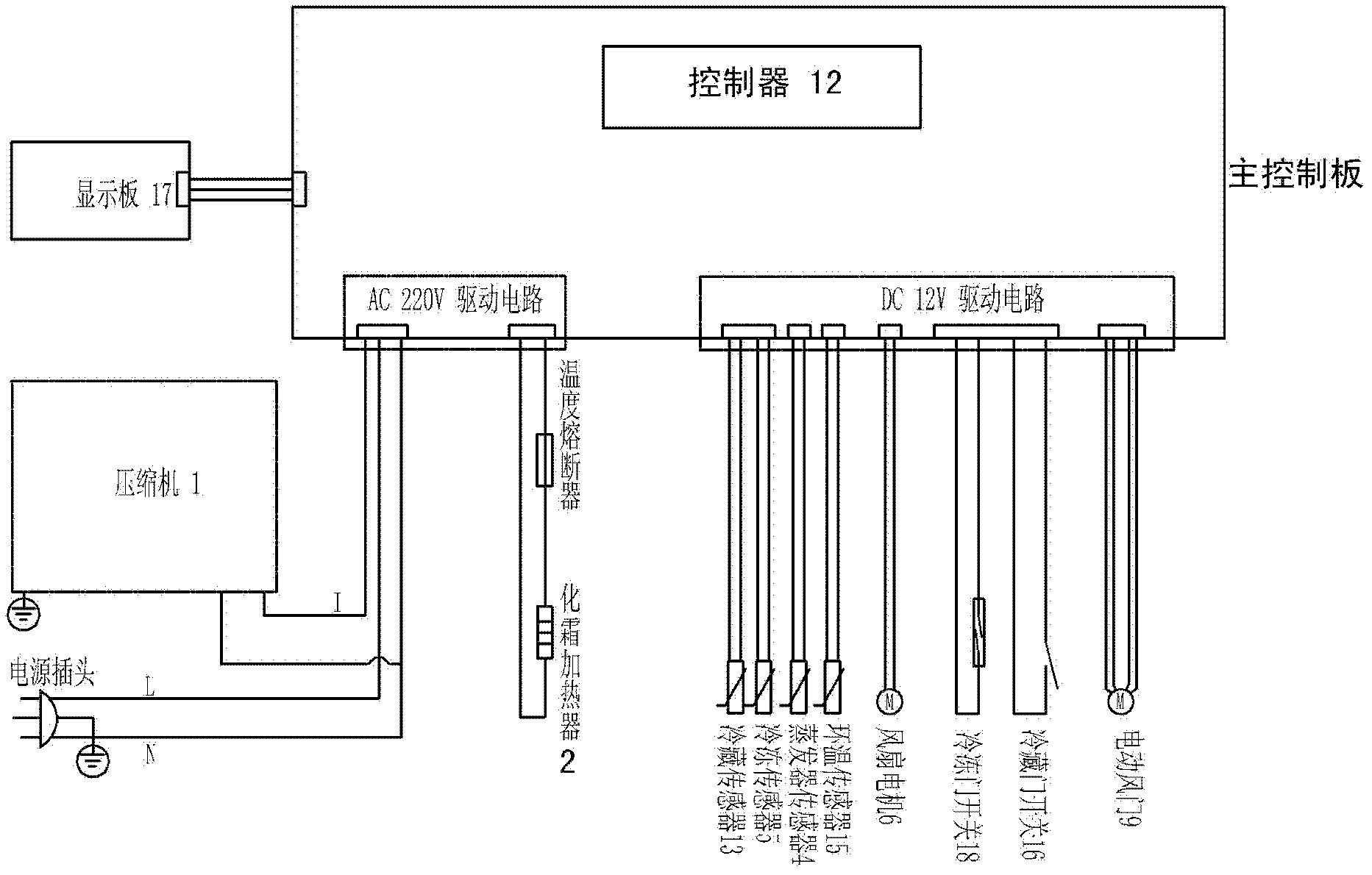

[0034] Example: figure 1 , image 3Respectively, a schematic diagram and a block diagram of the structure of the control system of the present invention, including a controller 12, an evaporator temperature sensor 4 connected to the controller 12, a freezer temperature sensor 5, a refrigerator temperature sensor 13 and an ambient temperature sensor 15, the controller (12) Integrates single-chip processing unit and high and low voltage hardware drive circuit, in which the high voltage part drives the defrost heater 2, compressor 1 and other components, and the low voltage part drives the sensor, door switch, evaporating fan 6, electric damper 9 and other components. The single-chip processor integrates the defrosting control method of the present invention, and judges whether the refrigerator needs defrosting according to the temperature values of the freezing chamber temperature sensor 5, the evaporator temperature sensor 4, the ambient temperature sensor 15 and the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com