An evaluation method for the smoke suppression performance of flame-retardant asphalt mixture

An asphalt mixture and evaluation method technology, which is applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problem that the combustion of asphalt mixture on the road cannot be well simulated, the test cost is high, and the smoke suppression performance evaluation test is difficult. and other problems, to achieve the effect of high feasibility, simple operation and good simulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

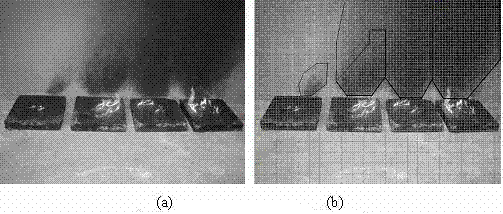

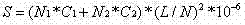

Image

Examples

Embodiment Construction

[0032] The present invention is described in further detail below by example.

[0033] 1. The technical properties of SBS modified asphalt are shown in Table 1. The test results show that the technical indicators of the SBS modified asphalt used in this test fully meet the specification requirements.

[0034] Table 1 Basic technical indicators of SBS modified asphalt

[0035] index Penetration (mm) 5°C ductility (cm) Softening point (°C) Flash point (°C) test results 50.0 31.5 80.6 285 skills requirement 40~60 ≥20 ≥60 ≥250

[0036] 2. The flame retardant used in the example is 1500-mesh magnesium hydroxide, and the dosage of the flame retardant is respectively selected as 4%, 7%, 10%, and 15% (accounting for the proportion of asphalt). The physical properties of magnesium hydroxide flame retardant are shown in Table 2.

[0037] Table 2 Physical properties of magnesium hydroxide flame retardant

[0038] flame retardant che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com