A heliostat calibration device and calibration method

A technology for calibrating equipment and heliostats, used in lighting and heating equipment, solar ray concentration, solar collector controllers, etc., can solve the focus position deviation, the complicated operation process, and the inability to realize the real-time rotation axis of the heliostat Correction and other problems to achieve the effect of ensuring accuracy and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

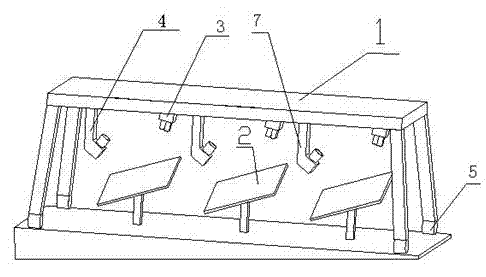

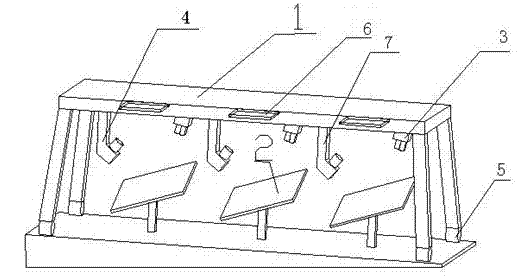

[0076] This embodiment provides a heliostat correction device, which includes a bracket, a laser correction system, and an image processing system,

[0077] The laser correction system is set on the bracket through a positioning device, which includes: at least one laser generator: used to emit laser light to the mirror surface of the heliostat, and the laser beam is reflected by the mirror surface of the heliostat to form a reflection spot on the correction equipment ; At least one image collector: it is set facing the area where the reflected light spot is formed, and is used to collect the image of the reflected light spot; at least one positioning unit: used to determine the spatial position information of the reflected light spot and the laser generator; the image processing system The reflected light spot collected by the image collector is received and the spatial position information of the mirror surface of the heliostat is determined in combination with the spatial po...

Embodiment 2

[0094] In this embodiment, on the basis of Embodiment 1, the positioning device includes a sliding rail arranged on the bracket, and the laser generator and the elbow-shaped support part are provided with a slider.

[0095] After the correction of one heliostat is completed, the positions of the laser generator and the image collector are changed by sliding to realize the correction of other heliostats.

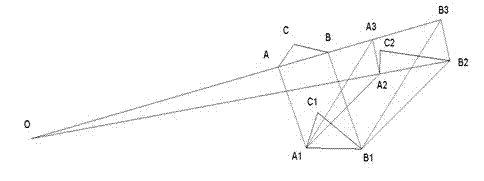

[0096] In this embodiment, each positioning unit includes at least three positioning modules, and the positioning modules are arranged on the support according to the principle that they are not on the same straight line. The at least three positioning modules can determine the positions of at least three points of the support, and the three points can determine a plane, thus further determining the spatial position of the support, and the laser generator and the The relative positional relationship between the image collector and the bracket is known, so that the spatial po...

Embodiment 3

[0101] In this embodiment, on the basis of Embodiment 1, the positioning device includes a 360-degree rotatable rotating mechanism arranged on the bracket, and the laser generator and the elbow support member are arranged on the rotating mechanism .

[0102] After the calibration of one heliostat is completed, the rotation mechanism is used to control the laser generator and the elbow support member to turn to different angles to realize the calibration of other heliostats.

[0103] In this embodiment, each positioning unit includes at least two positioning modules and at least one tilt angle sensing module arranged on the bracket;

[0104] The spatial position of the support can be determined by combining the inclination angle of the support with the positions of two points of the support, and the relative positional relationship between the laser generator and the image collector and the support is known, so as to determine The spatial positions of the laser generator, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com