A heliostat calibration device and calibration method

A technology for correcting equipment and heliostats, which is applied to lighting and heating equipment, solar ray concentration, solar collector controllers, etc., can solve the focus position deviation, cumbersome operation process, and the real-time rotation of the heliostat’s rotation axis cannot be realized. Calibration and other problems, to achieve the effect of accurate spatial position and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

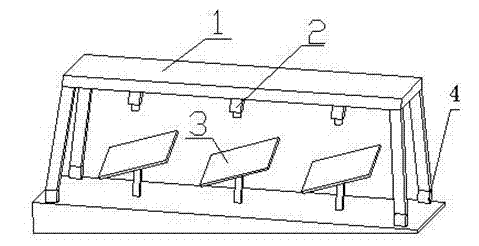

[0055] This embodiment provides a movable heliostat correction device, which includes a bracket, an image acquisition unit and an image processing unit;

[0056] The image acquisition unit is arranged on the support through a positioning device, including:

[0057] At least one camera: used to collect mirror state images of heliostats;

[0058] At least one positioning unit: used to determine the spatial position of the camera;

[0059] The image processing unit is used to receive the image of the state of the mirror surface collected by the camera, and determine the spatial position information of the mirror surface of the heliostat in combination with the spatial position information of the camera.

[0060] In this embodiment, the position detection module includes at least three positioning modules arranged on the support, and the positioning modules are DGPS (Differential Global Positioning System) positioning modules.

[0061] DGPS is the abbreviation of Difference Glob...

Embodiment 2

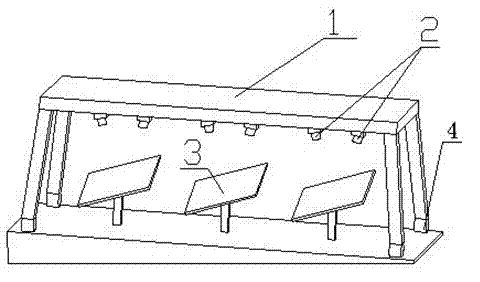

[0090]The difference between this embodiment and Embodiment 1 is that the positioning device includes a 360-degree rotatable rotating mechanism arranged on the bracket, and the image acquisition unit includes a camera, and the camera is arranged on the rotating Institutional.

[0091] In the step a of determining the center of rotation of the heliostat, the rotating mechanism is used to control the camera to take images of the mirror surface of the heliostat under at least two angles to obtain the image of the mirror surface of the heliostat;

[0092] Moreover, after the calibration of one heliostat is completed, the other heliostats can be calibrated by repeating steps b and c by rotating the angle of the camera.

Embodiment 3

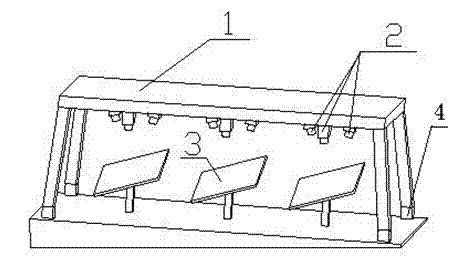

[0094] In this embodiment, the image acquisition unit includes two cameras, and the two cameras are fixed on the bracket through the positioning device.

[0095] In this embodiment, an inclination sensor arranged on the bracket and at least two positioning modules arranged on the camera and the bracket are used instead of the positioning module arranged on the bracket described in the above embodiment. Set at least three positioning modules that are not in the same straight line principle.

[0096] The spatial position of the support and the spatial position of each camera are determined through a combination of an inclination sensor disposed on the support and at least two positioning modules disposed on each camera.

[0097] In the step a of determining the rotation method of the heliostat, the two cameras are used to obtain two images of the mirror state of the heliostat in the current state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com