Online Alignment of Process Analytical Models to Actual Process Operations

A process model, model technology, applied in the direction of program control, comprehensive factory control, instrumentation, etc., can solve problems such as poor analysis results, unsatisfactory, misleading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

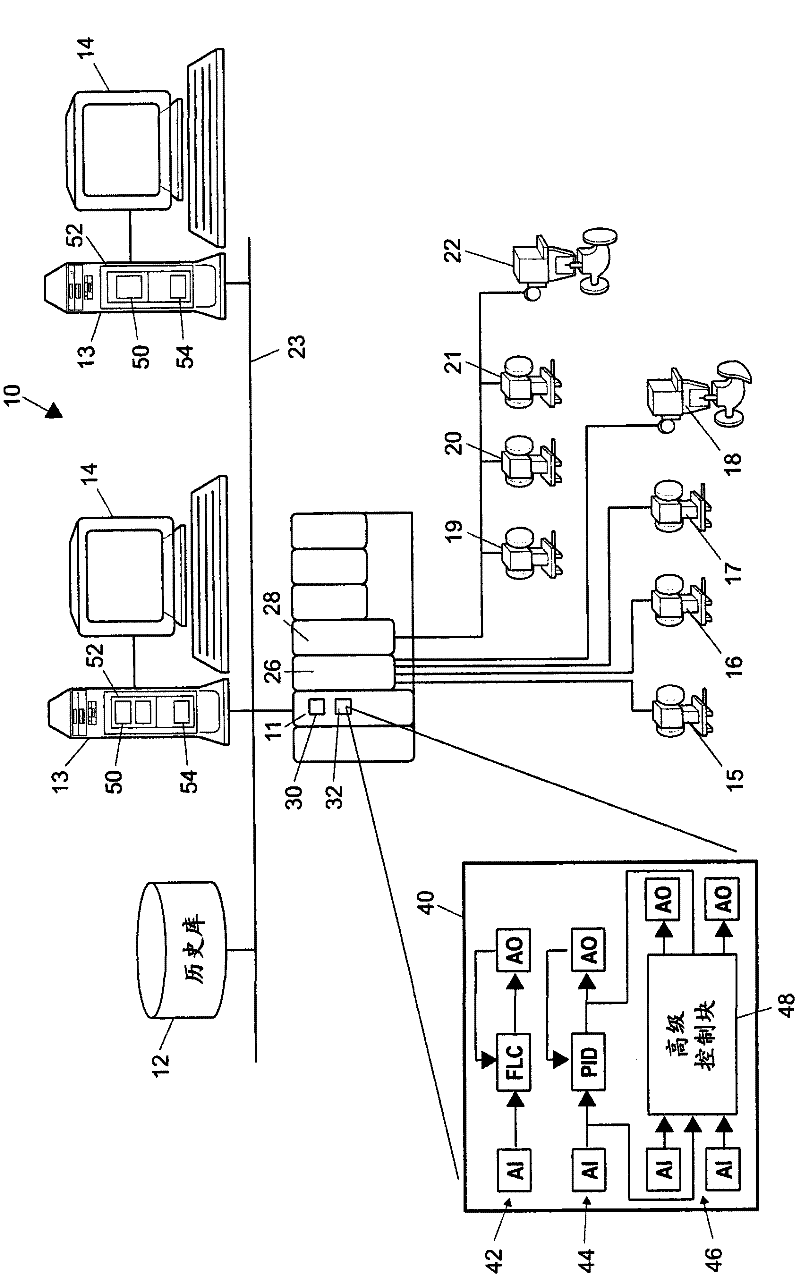

[0030] figure 1 An exemplary process control system 10 is shown, including a process controller 11 connected to a data history database 12 and one or more main workstations or computers 13 (which may be any type of personal computer, workstation, etc.), each of the main workstations Or the computer 13 has a display screen 14. The controller 11 is also connected to the field devices 15-22 through input / output (I / O) cards 26 and 28, and can operate to implement one or more batch operations of the batch process using the field devices 15-22. The data history library 12 may be any required type of data collection unit, which has any required type of memory and any required or known software, hardware, or firmware for storing data. The data history database 12 can be separated from one of the workstations 13 (e.g. figure 1 Shown), or a part of one of the workstations 13. The controller 11, which may be, for example, the one sold by Emerson Process Management The controller is comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com