A cryocooler directly cools a superconducting magnet with a mechanical thermal switch

A technology of superconducting magnets and refrigerators, applied in superconducting magnets/coils, thermal switch components, magnetic objects, etc., can solve the problems of small heat capacity and switch ratio, increased heat leakage, and low heat transfer power , to achieve the effect of ensuring effective utilization, convenient and reliable operation, and strong conduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

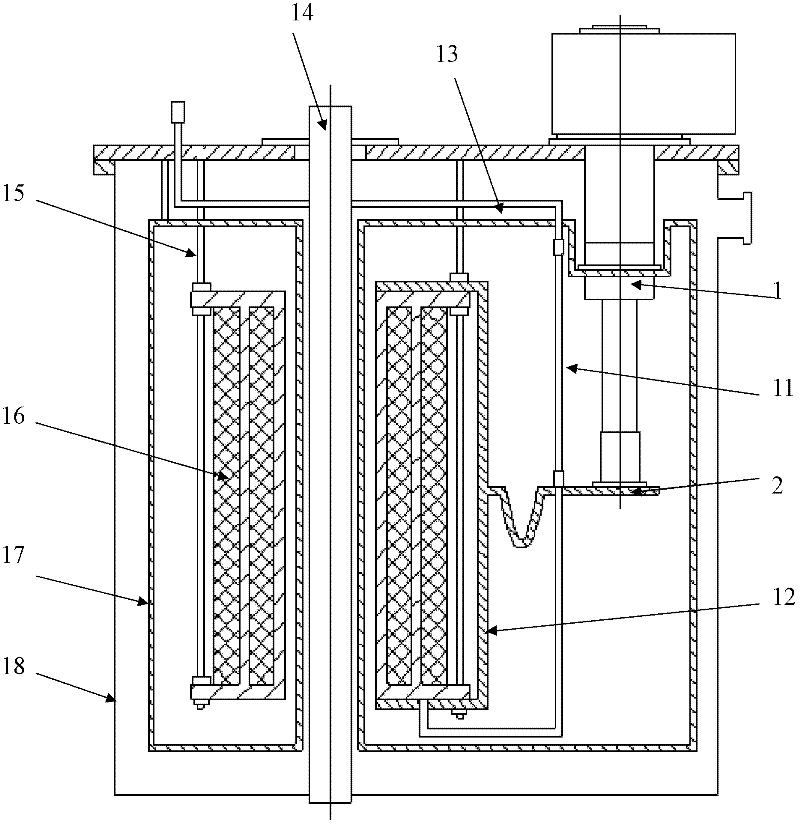

[0018] Such as figure 1 The superconducting magnet system directly cooled by the refrigerator includes the first-stage cold head 1 of the refrigerator, the second-stage cold head 2 of the refrigerator, the high-temperature superconducting current lead 11, the conduction plate 12, the copper wire 13, the room-temperature aperture 14, the support structure 15, and the superconducting magnet. Conductive coil 16, radiation shield 17 and vacuum container 18.

[0019] The mechanical thermal switch for directly cooling the superconducting magnet by the refrigerator of the present invention can be applied to the above-mentioned system for directly cooling the superconducting magnet by the refrigerator.

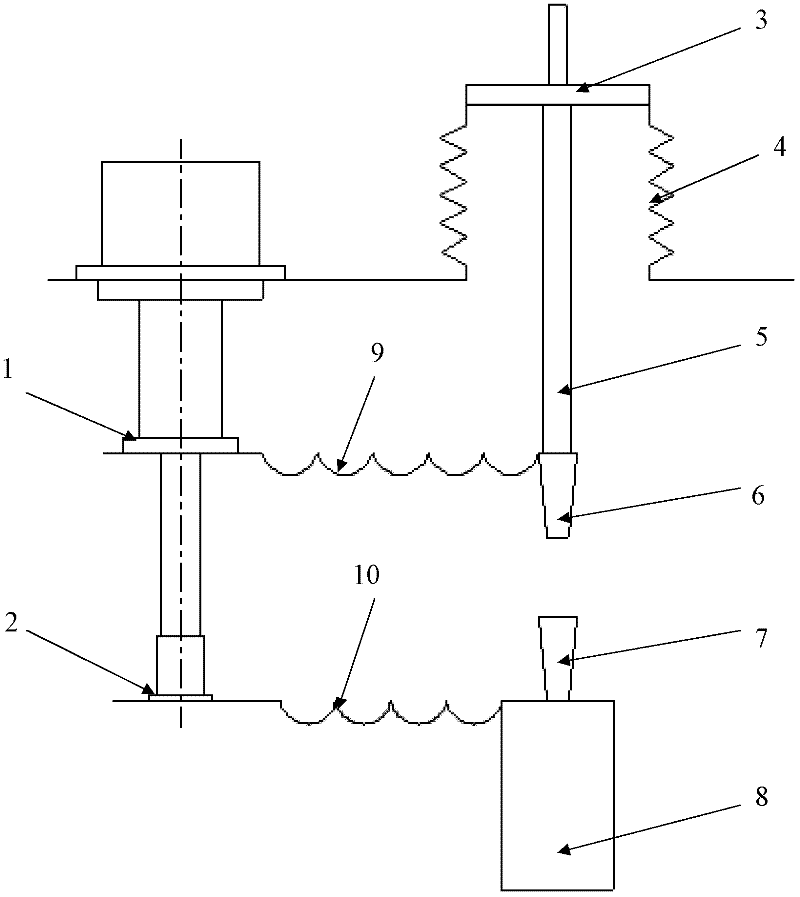

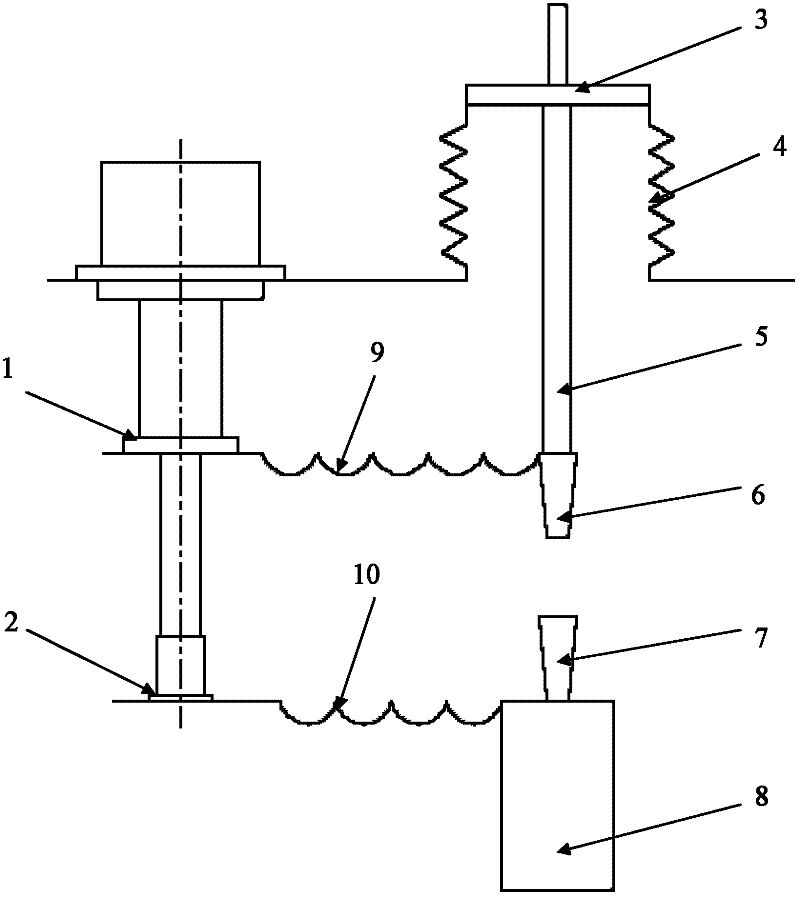

[0020] Such as figure 2 , a mechanical thermal switch for direct cooling of superconducting magnets by a refrigerator, comprising bellows upper flanges 3 bellows 4, glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com