A kind of plastic encapsulation mold and upper lead wire and lower lead wire therein

A plastic sealing mold and lead bar technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high matching requirements, pin beading or plastic sealing compound residue, high matching requirements of plastic sealing molds and lead frames, etc. , to achieve the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

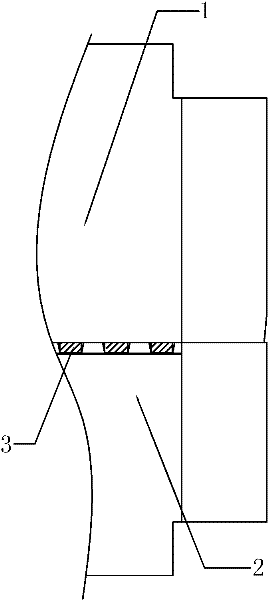

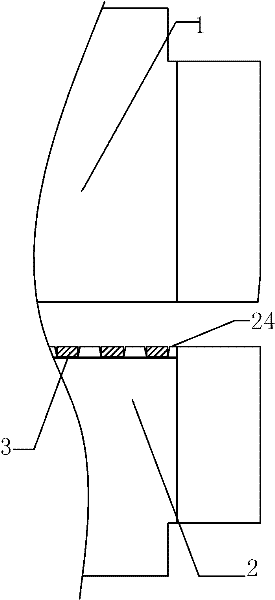

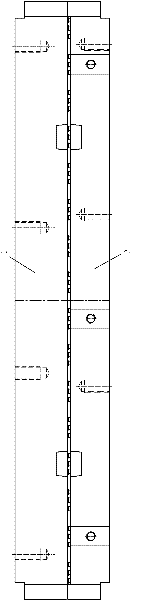

[0030] Figure 2A It is a structural schematic diagram of the closed state of the upper lead wire and the lower lead wire in the plastic sealing mold according to the present invention; Figure 2B It is a structural schematic diagram of the separation state of the upper lead bar and the lower lead bar in the plastic packaging mold according to the present invention. Such as Figure 2A and Figure 2B As shown, the upper lead bar 1 and the lower lead bar 2 include 16 packaging positions, each of which can package a device. The upper and lower lead bars have a structure of insertion, that is to say, relative to the position of the lead groove of the lower lead bar, the upper lead bar is provided with a raised part, and the raised part just blocks the notch part of the lead groove when it is closed. , Seal the lead groove from the top and upper side. Although in Figure 2A and 2B In the illustrated embodiment, each package has three lead slots, correspondingly each device ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com