Building photovoltaic integrated hollow type amorphous silicon solar cell module and manufacturing method

A technology of solar cells and amorphous silicon, which is applied in building components, photovoltaic power generation, construction, etc., can solve the problems of poor impact resistance, low tensile strength, frequent changes and calibrations of fixtures, etc., and achieve increased barrier shielding, Improve the effect of temperature insulation and reduce the degree of strong light aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

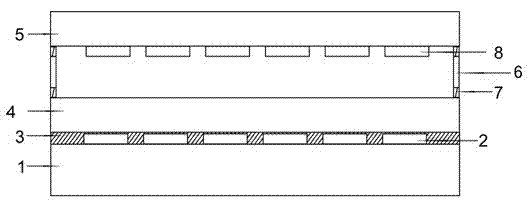

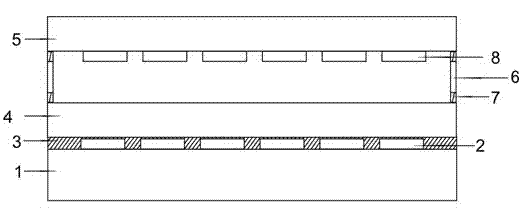

[0020] The building photovoltaic integrated hollow amorphous silicon solar cell assembly of the present invention is a laminated structure, including a front encapsulation glass 1, an amorphous silicon cell layer 2, an adhesive film connection layer 3, a tempered glass 4, and a colored crystal glass back arranged in sequence. Plate 5; tempered glass 4 and color crystal glass back plate 5 are fixed by setting hollow aluminum strips 6 around, and polysulfide glue 7 is applied to the edge of the hollow aluminum strip 6 for sealing, and the inner side of the color crystal glass back plate 5 is provided with Color Crystal Decorative Coating 8.

[0021] The front encapsulating glass 1 is ultra-clear rolled glass, ultra-clear float glass, ordinary float glass or the above glass coated with anti-reflection film, and has a thickness of 2-6 mm.

[0022] The color crystal glass back panel 5 is ultra-white float glass or ordinary float glass, with a thickness of 2-6mm.

[0023] The manuf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com