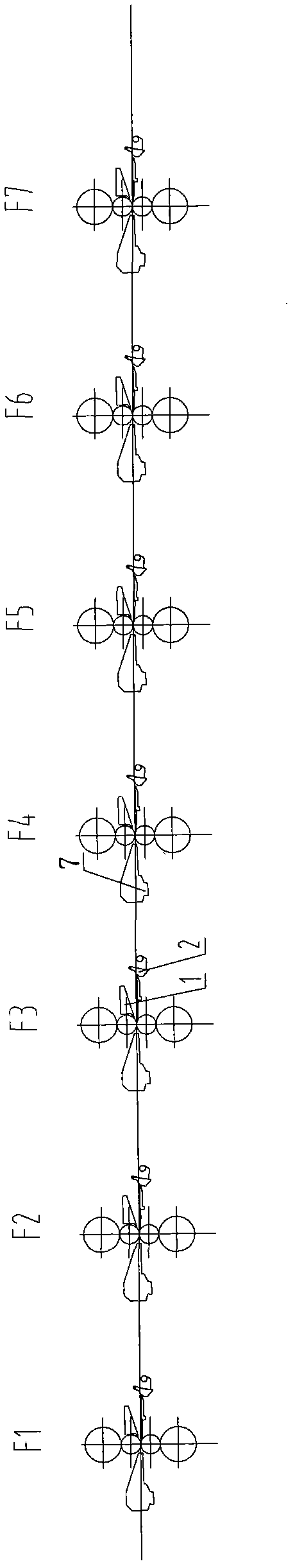

Intermediate additional cooling equipment and method for hot continuous rolling plate band

A technology of cooling equipment and cooling method, which is applied in the direction of metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problems of application range influence, thin and wide specification restrictions, etc., so as to alleviate the problem of stacking steel, increase added value, The effect of expanding the thickness range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following is a detailed description of an intermediate additional cooling device and method for hot continuous rolling strips of the present invention through examples and accompanying drawings.

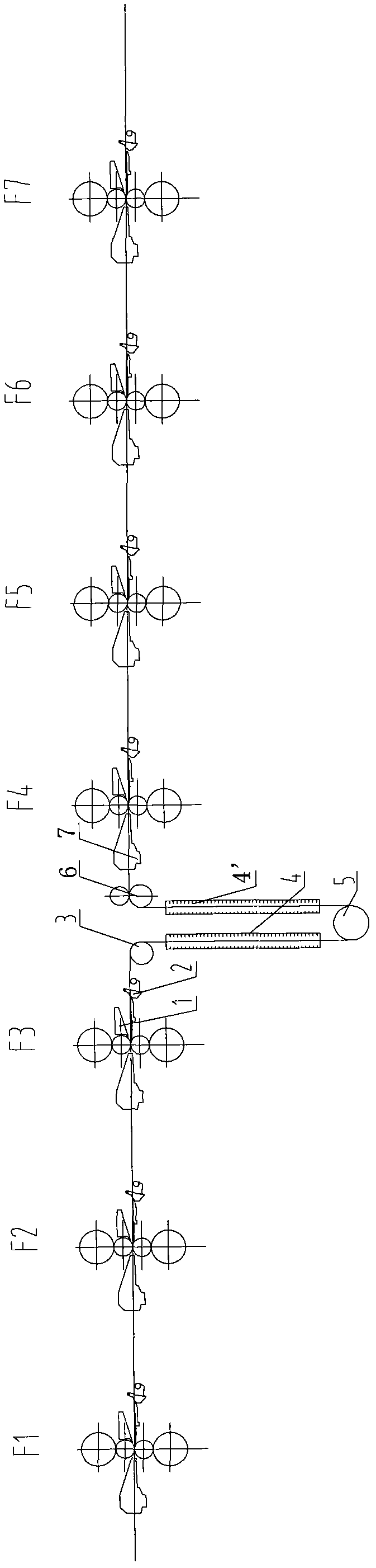

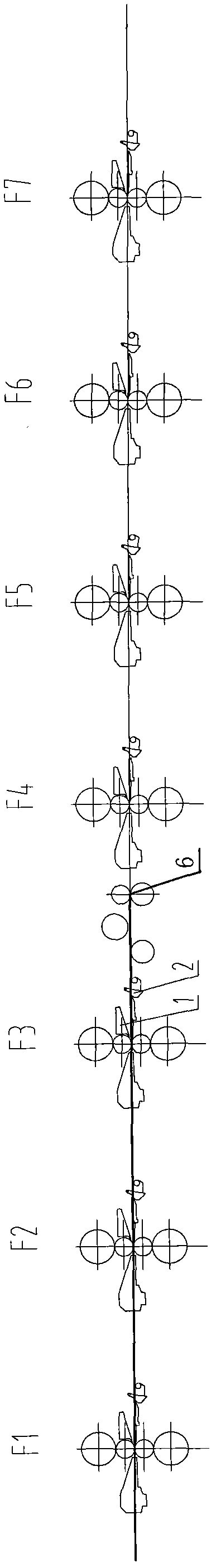

[0035] Such as figure 2 As shown, the intermediate additional cooling equipment for hot strip rolling mainly includes turning rolls 3, at least one cooling device 4 and / or 4', long-stroke looper rolls 5 and pinch rolls 6. Here, take two cooling devices as an example, including a first cooling device 4 and a second cooling device 4'. The steering roll 3 and the pinch roll 6 are set up and down along the conveying line of the hot strip, and the first cooling device 4, the long-stroke looper roll 5 and the second cooling device 4' are all movably arranged on the steering roll 3 and the pinch roll. between rollers 6.

[0036] The steering roller 3 is arranged behind the guard plate 1 at the exit of the rolling mill and the looper pick 2 between the racks. The guard plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com