Outer-diameter superfinishing machine tool for spherical roller

A technology of spherical rollers and machine tools, applied in superfinishing machines, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing thermal stress on the roller surface, large roughness value, and reducing the service life of bearings, etc., to achieve optimal super The effects of fine workmanship, surface quality improvement and bearing quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

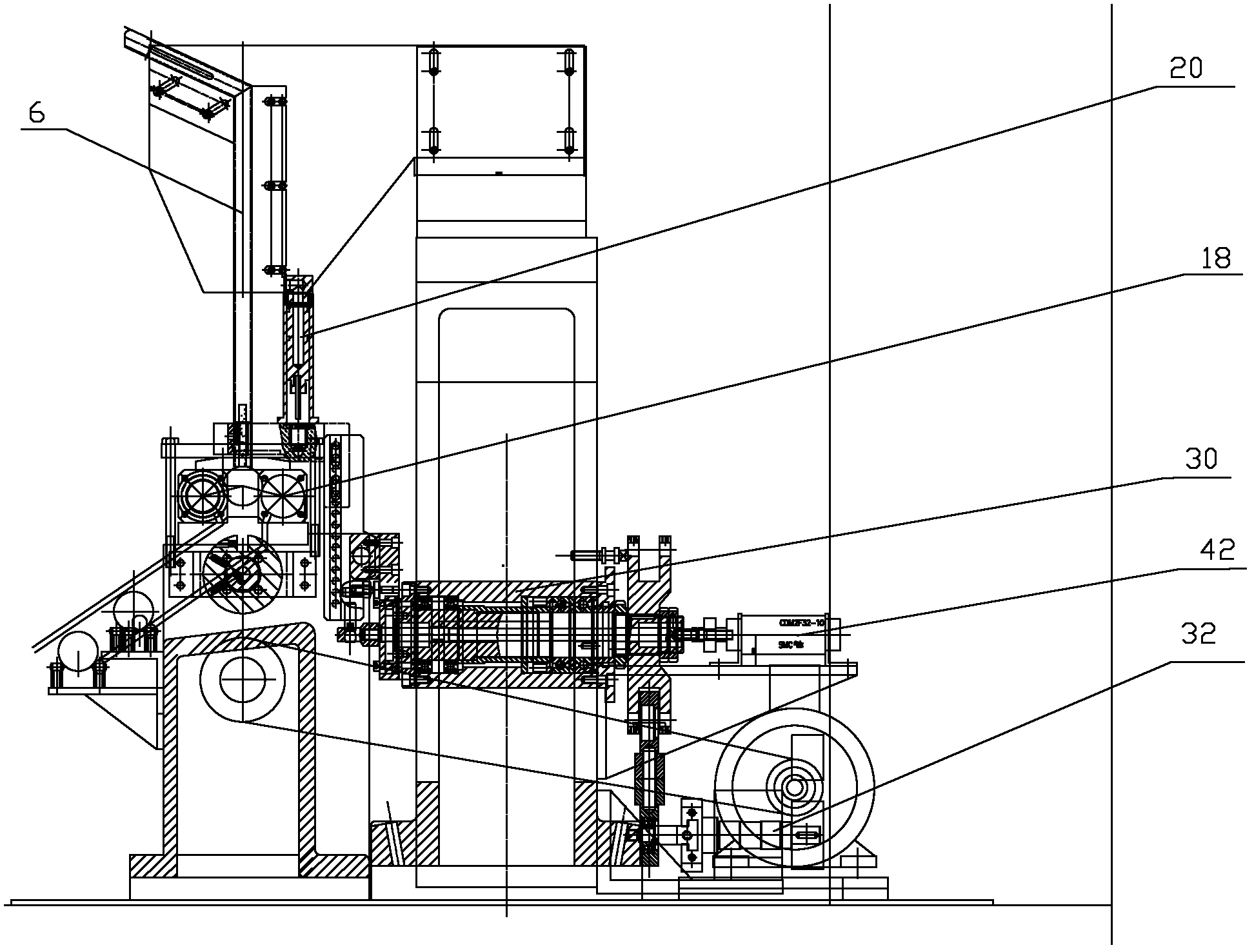

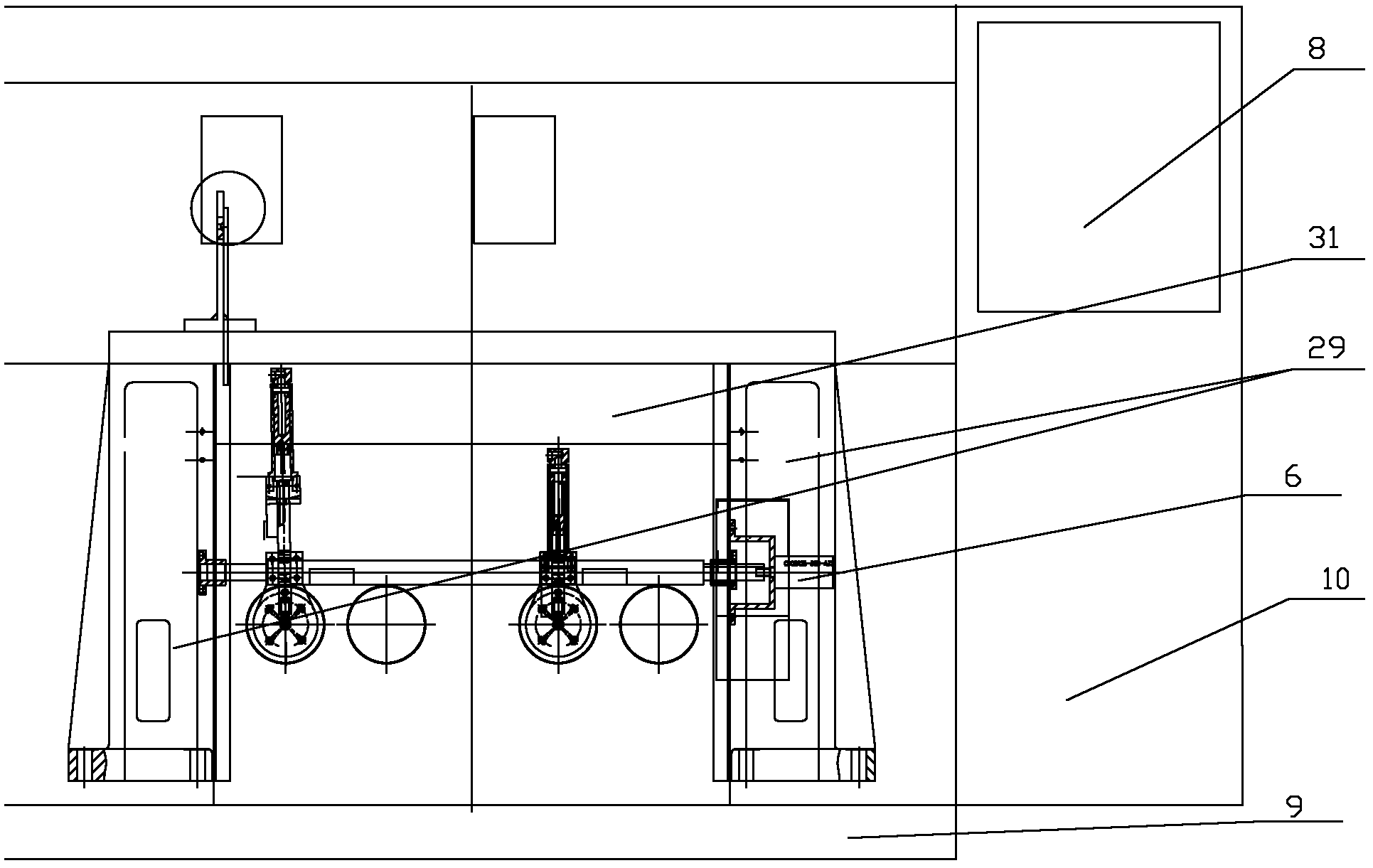

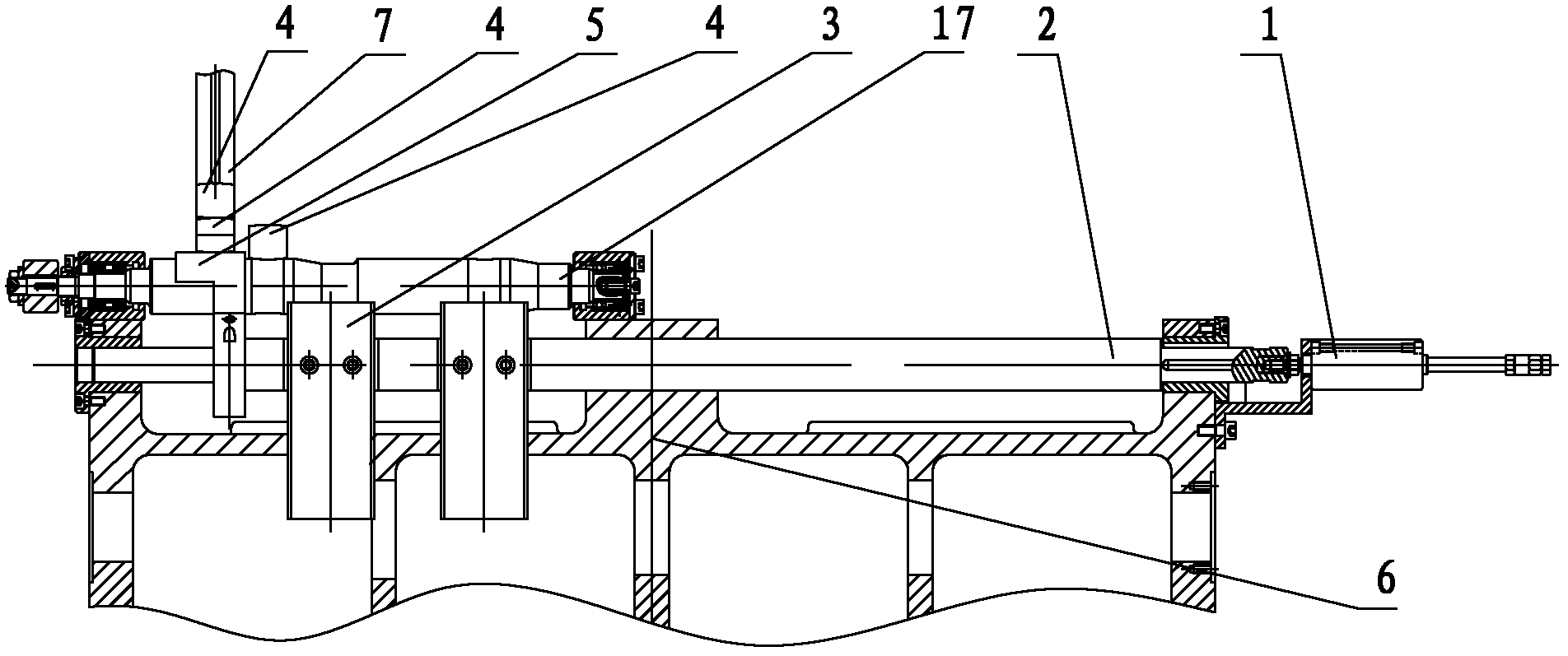

[0027] Such as figure 1 , figure 2 As shown, it includes a bed 9, an electrical control cabinet 10, a cooling mechanism, a loading and unloading mechanism 6, a workpiece transmission mechanism 18, a swing mechanism 32 and an ultra-precision mechanism 20, and a column 29 is arranged on the bed, and the column 29 is two left and right columns , the left and right columns 29 are mounted on the rear part of the workpiece transmission mechanism 18, the front portion of the bed 9 is equipped with the workpiece transmission mechanism 18, the left and right columns 29 are equipped with a vertically movable box 31, and the swing mechanism 32 includes a swing spindle 30 And...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com