Sealant of liquid crystal panel and modification method thereof

A technology for sealing frame glue and liquid crystal panels, which is applied in the direction of adhesives, nonlinear optics, adhesive types, etc., and can solve problems such as pollution and material miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

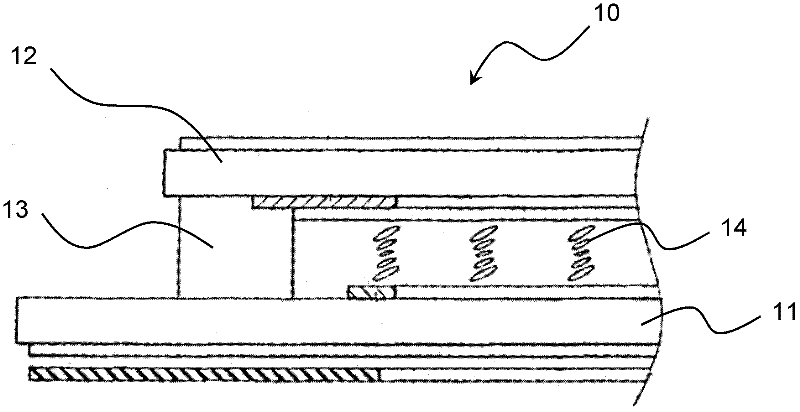

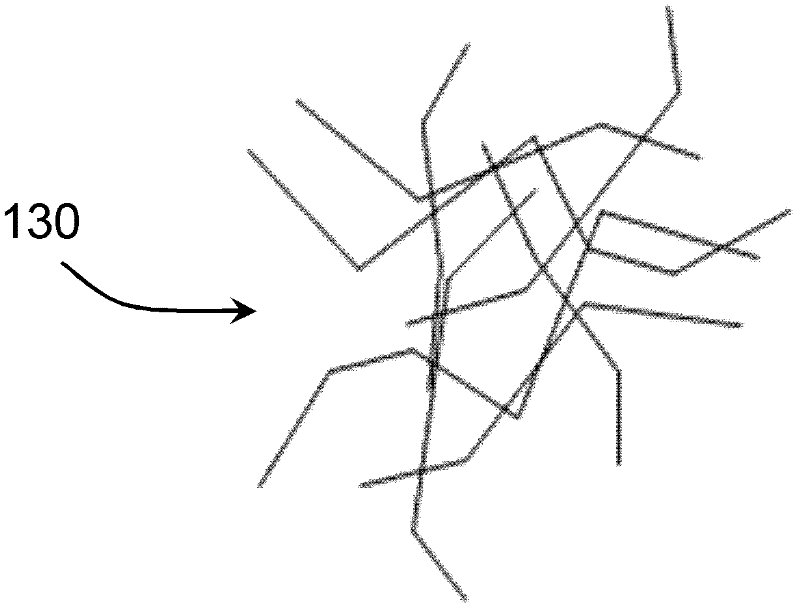

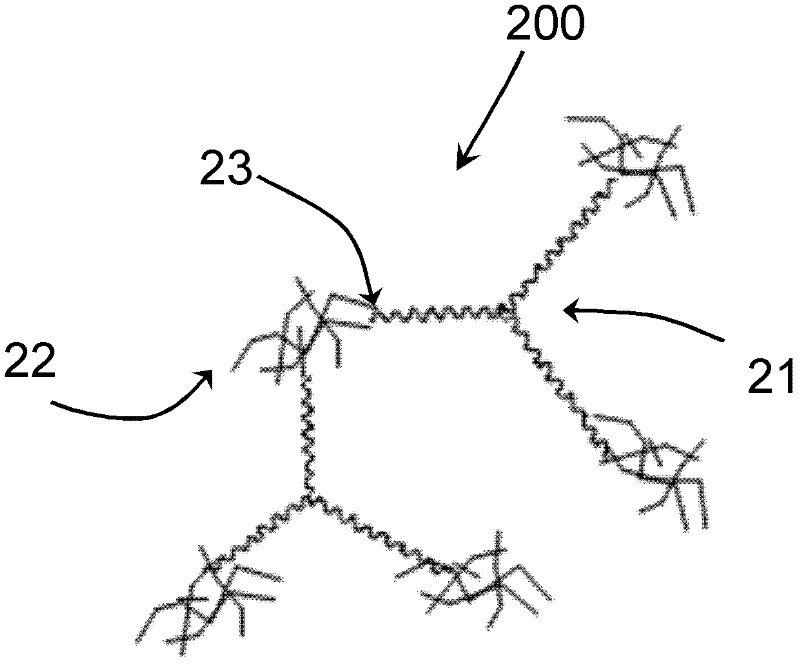

[0036] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be practiced.

[0037] 1. Experimental raw materials:

[0038] Diisocyanate reactants, trifunctional reactants (also known as moderately flexible reactants), acetone or butanone, bromophenol blue, di-n-butylamine, hydrochloric acid, toluene, isopropanol.

[0039] The above-mentioned diisocyanate reactants can be selected from hexamethylene diisocyanate (HDI), toluene diisocyanate (TDI) or diphenylmethane-4,4'-diisocyanate (MDI), such as choosing to use hexamethylene diisocyanate (HDI);

[0040] The above-mentioned trifunctional reactants (moderately flexible reactants) can be selected from polyether triols, polycaprolactone triols or polycarboxylic acid terpolymers, such as polyether triols;

[0041] The epoxy resin monomer can be epichlorohydrin or other aromatic epoxy resin monomers, preferably bisphenol A typ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com