Lug bolted lithium ion battery

A technology of lithium-ion batteries and tabs, which is applied to battery pack components, circuits, electrical components, etc., can solve problems such as complex processes and unstable connection methods between cells and electrodes, and achieves overcoming complex processes and solving the problem of outer poles. Concentration of ear stress and effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

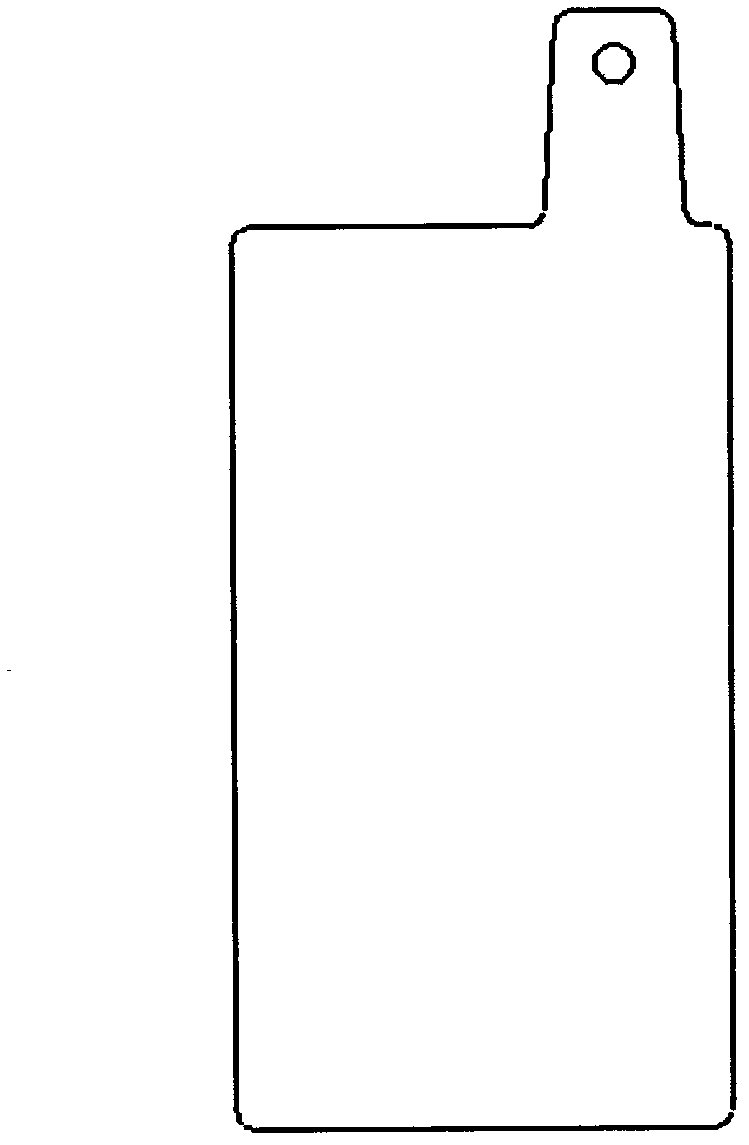

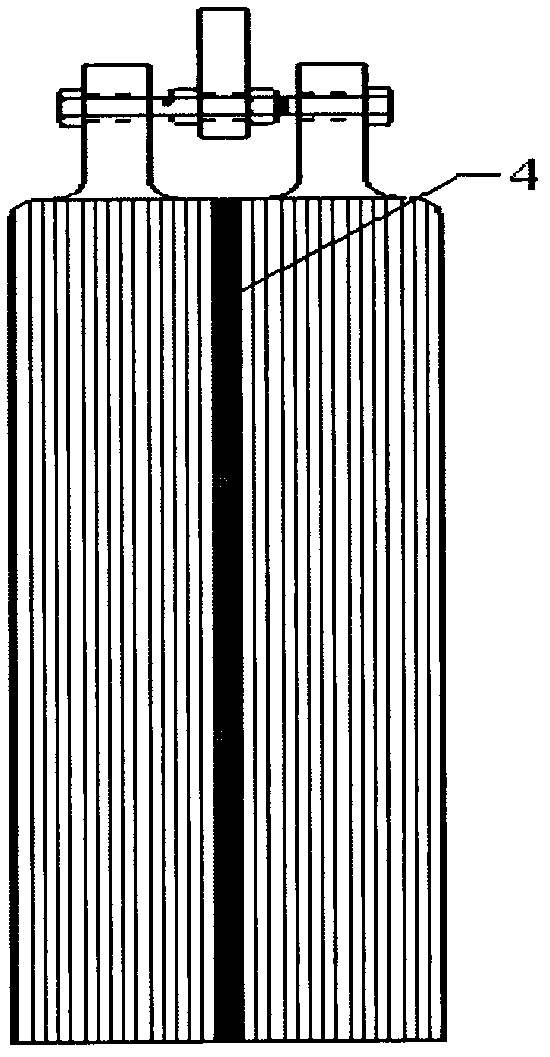

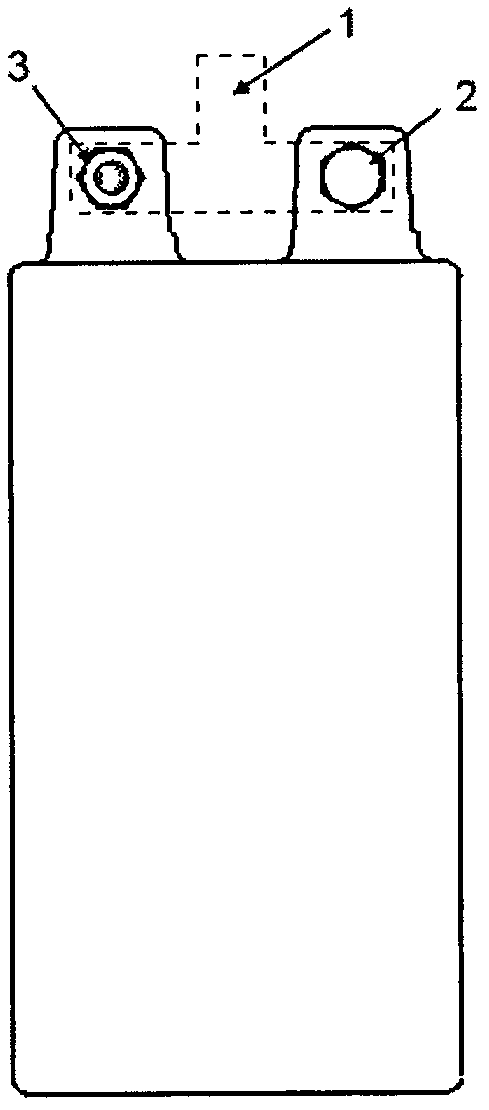

[0016] Embodiment 1: A kind of lug-connected lithium-ion battery comprises a cell and a casing, and the cell is placed in the casing, such as figure 2 , 3 As shown, there are two electric cores stacked together, and there is a diaphragm 4 between the two electric cores; figure 1 As shown, there are bolt holes on the lugs of each cell, the positive lugs and the negative lugs are connected together with bolts 2 and nuts 3, and the bolts 2 between the lugs are pierced with gaskets, and the lugs between the lugs The bus bar electrodes 1 are also pierced on the bolts 2 .

Embodiment 2

[0017] Example 2, such as Figure 4 As shown, the tabs of cell group 1 7 and cell group 2 8 are bent 90 degrees to each other and stacked, then the bolt 2 is passed through the stacked tab hole, and finally it is tightened with the nut on the electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com