Automated sample injection apparatus, multiport valve, and methods of making and using the same

一种注射装置、多端口的技术,应用在测量装置、运输和包装、薄料处理等方向,能够解决仪器不知道、限制操作员生产力、增加操作员误差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

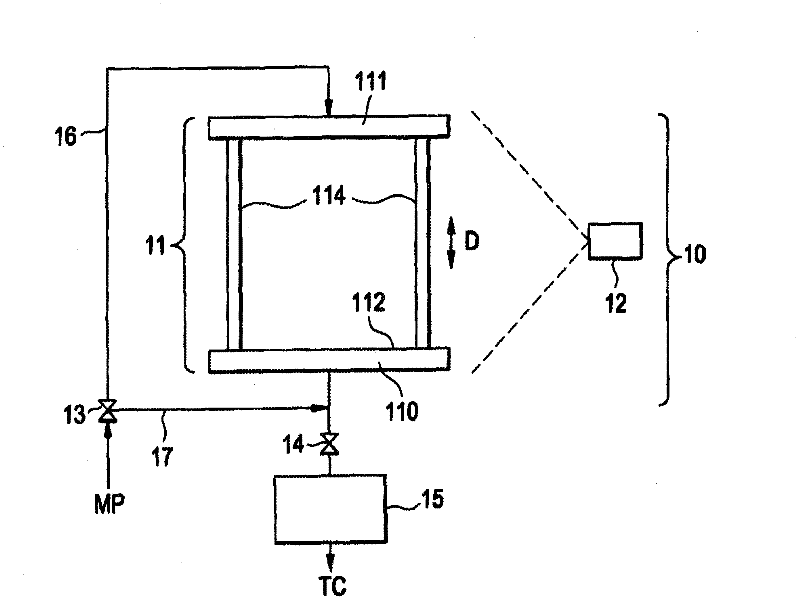

[0089] Use of Reveleris incorporating a valve according to the invention TM Flash chromatography system to purify liquid samples. In step one, the valve is set to position 1, where 12g Reveleris TM The silica cartridge was equilibrated with 95 / 5 hexane / ethyl acetate at 25 mL / min for 4 minutes. The valve is then moved to a second position where the cartridge inlet is connected through the valve to the sample loading syringe. Load 4 ml samples containing 10 mg / ml each of dioctyl phthalate, alpha tocopherol, and delta tocopherol into a syringe, attach the syringe to the valve and push onto the head of the column. The valve was then switched back to position 1 and a separation was created by flowing 95 / 5 hexane / ethyl acetate through the cartridge at 25 mL / min until all three compounds eluted from the column (approximately 10 minutes). Simultaneously compressed air flows through the valve to the nebulizer on the ELSD. Thereafter, the valve is switched to the third position wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com