Storage battery lead terminal casting mould

A technology of casting molds and lead terminals, which is applied in the field of battery manufacturing, can solve problems such as deformation of lead terminals, achieve the effects of reducing product defective rate, avoiding deformation or damage, and ensuring beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific embodiments and in conjunction with the accompanying drawings. The following examples only further illustrate the present invention, and should not be construed as limiting the present invention.

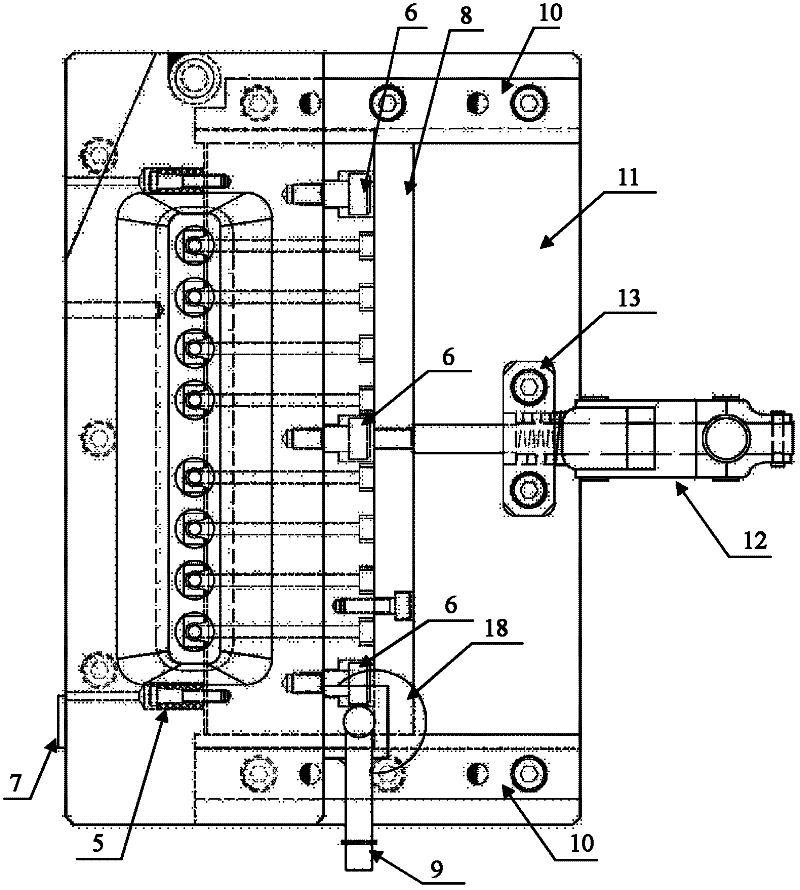

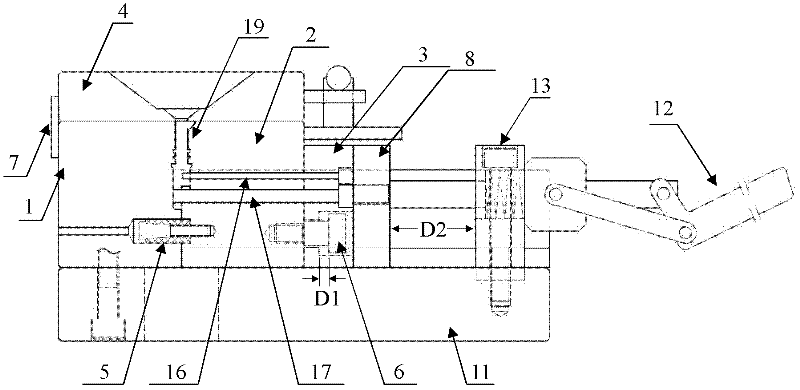

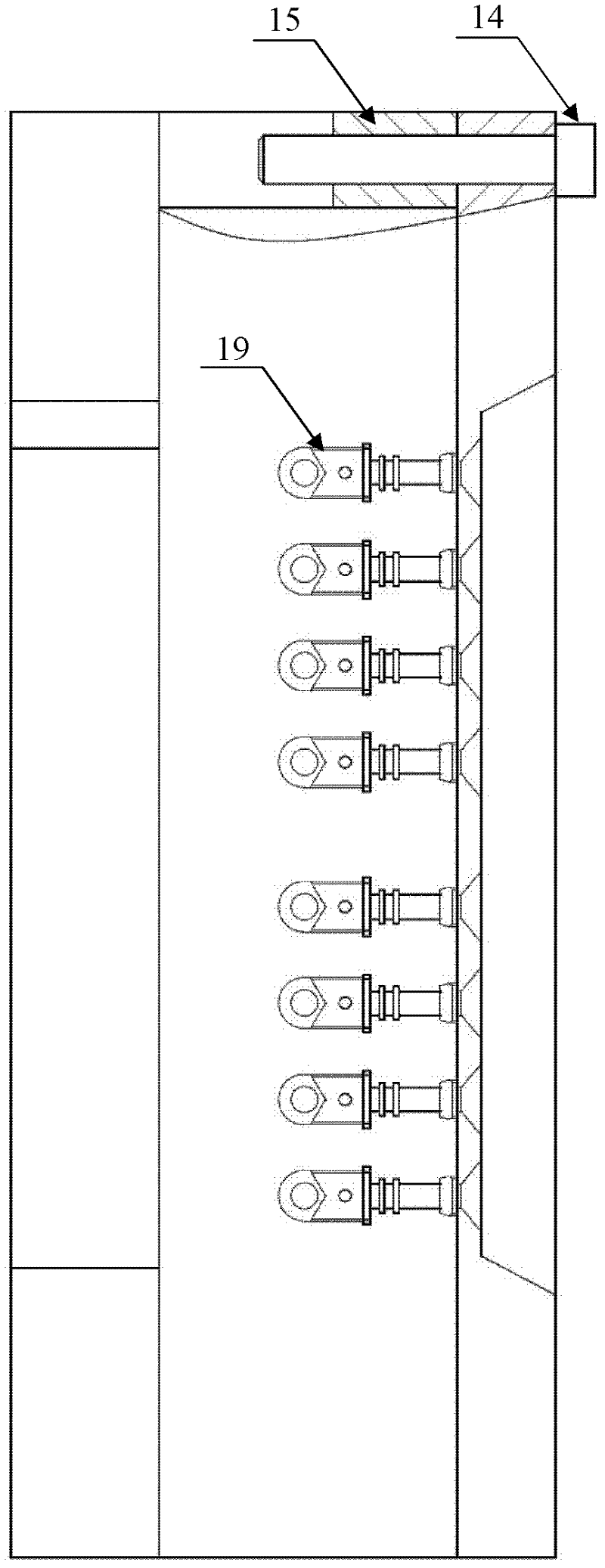

[0023] The casting mold of the present invention includes a sprue plate 4, a handle 9, a left template 1, a positioning plate 2, a positioning block 10, a bottom plate 11, a quick clip 12, a nylon buckle 5, a plug screw 6, a block 7, The first pressing block 3, the second pressing block 8, the limit block 13, the rotating shaft 14, the bushing 15, the first inserting pin 16, the second inserting pin 17, screws and pins for assembly, etc. The left template 1 is fixed on the bottom plate 11 with screws, the sprue plate 4 is connected by the rotating shaft 14 and the bush 15, and the bush 15 is welded on the left template 1; the row plate 2 is assembled on the right side of the left template 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com