Cam focusing mechanism employing backlash elimination gear

A gear and gap technology, applied in the field of optical focusing, can solve the problems of return error, low focusing precision, and inability to adjust the perpendicularity between the optical axis of the optical component and the camera image plane, so as to eliminate the return error and improve the focusing precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

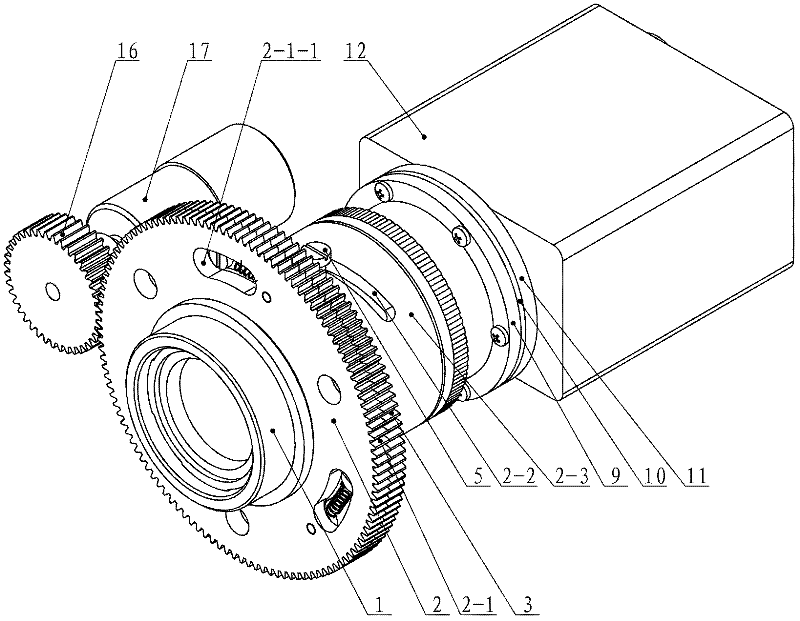

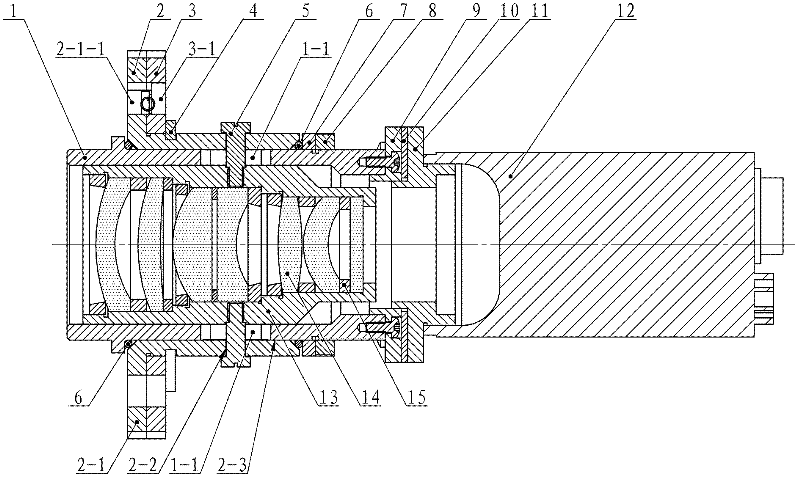

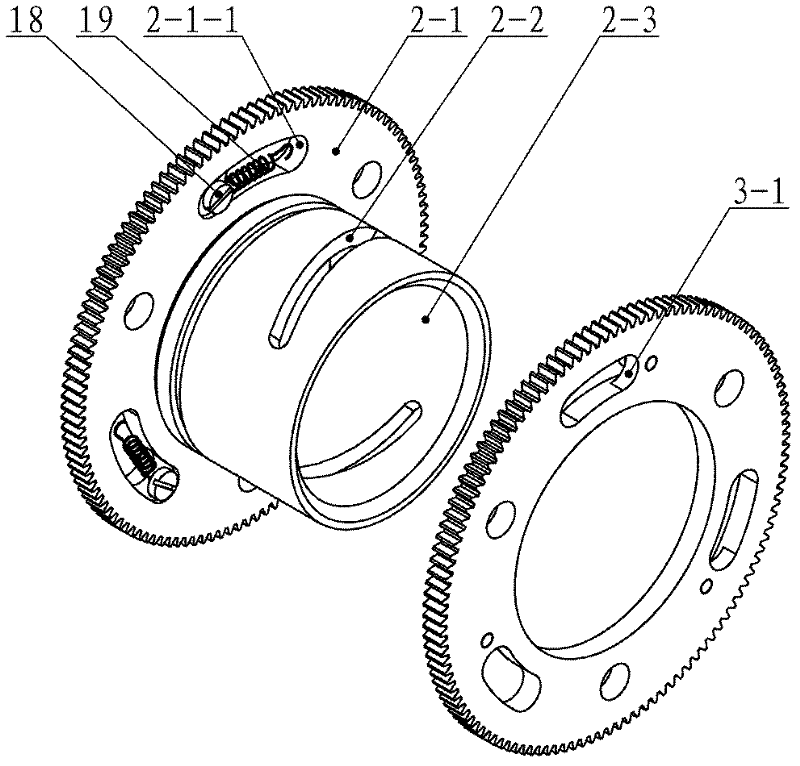

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as Figure 1 to Figure 3 As shown, the cam focusing mechanism using the anti-backlash gear in the present invention includes: a linear groove sleeve 1, a gear-cam groove sleeve 2, an anti-backlash gear 3, a shaft circlip 4, a focusing pin 5, and a steel ball 6 , retaining ring 7, nut 8, flange assembly, motor gear 16, motor 17, fixing nail 18 and spring 19. Among them, the flange assembly is composed of a sleeve flange 9, a flange gasket 10 and a camera flange 11, and the gear-cam groove sleeve 2 is composed of a gear plate 2-1, a cam groove 2-2 and a sleeve 2-3 . The focus mechanism adjusts the focus of the optical components of the camera 12 .

[0014] Such as figure 2 As shown, the gear-cam groove sleeve 2 of the present invention fits on the outside of the linear groove sleeve 1, and the gear-cam groove sleeve 2 and the backlash eliminati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com