Magnetron and thin film deposition treatment equipment applying same

A magnetron and magnet technology, applied in the field of microelectronics, can solve problems such as poor uniformity, hindering the continuous filling of pores, and difficulty in controlling the operation accuracy, so as to ensure uniformity and symmetry, improve uniformity and symmetry, and ensure The effect of scan accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the magnetron provided by the present invention and the thin film deposition processing equipment using the magnetron will be described in detail below with reference to the accompanying drawings.

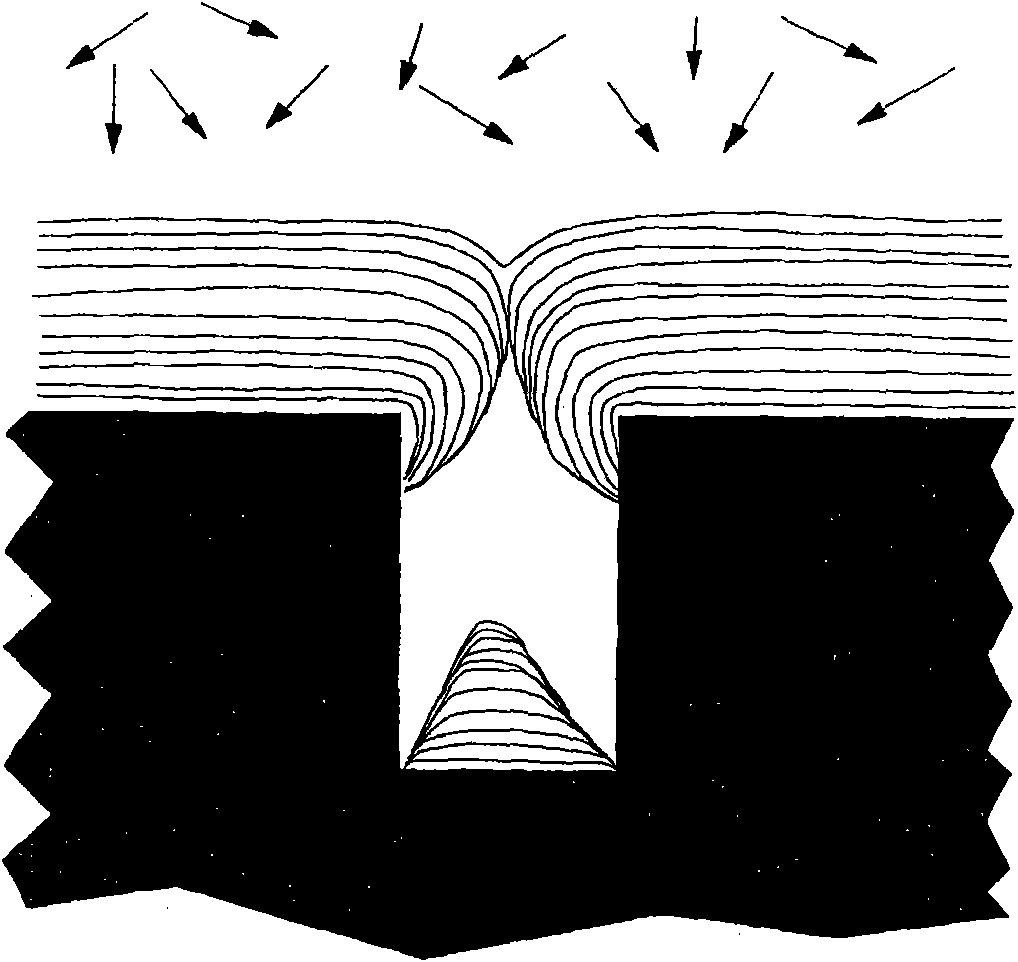

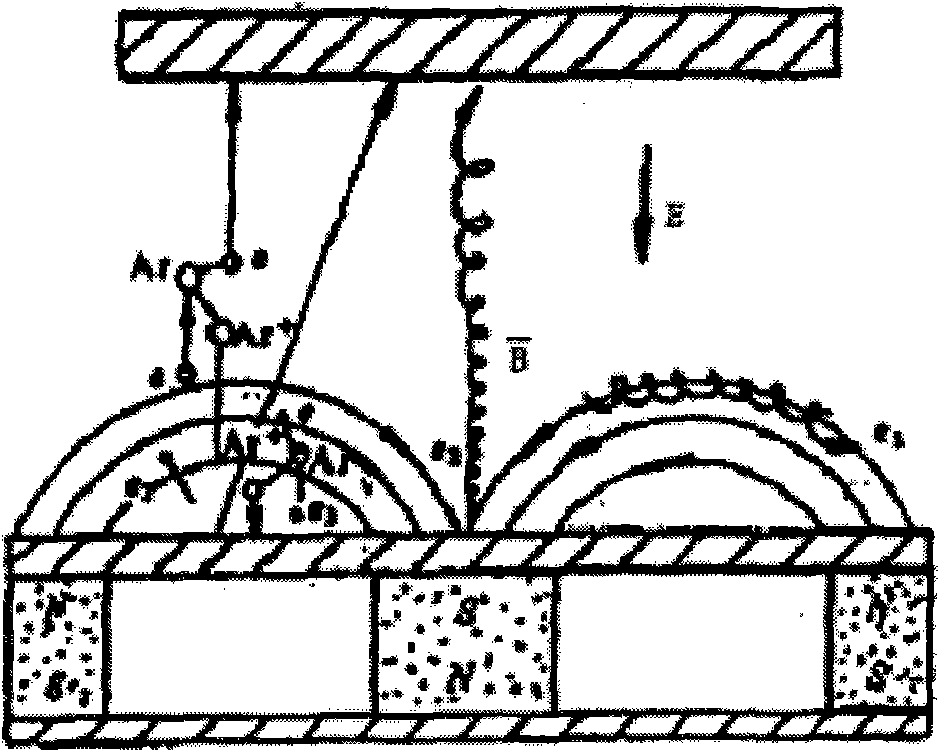

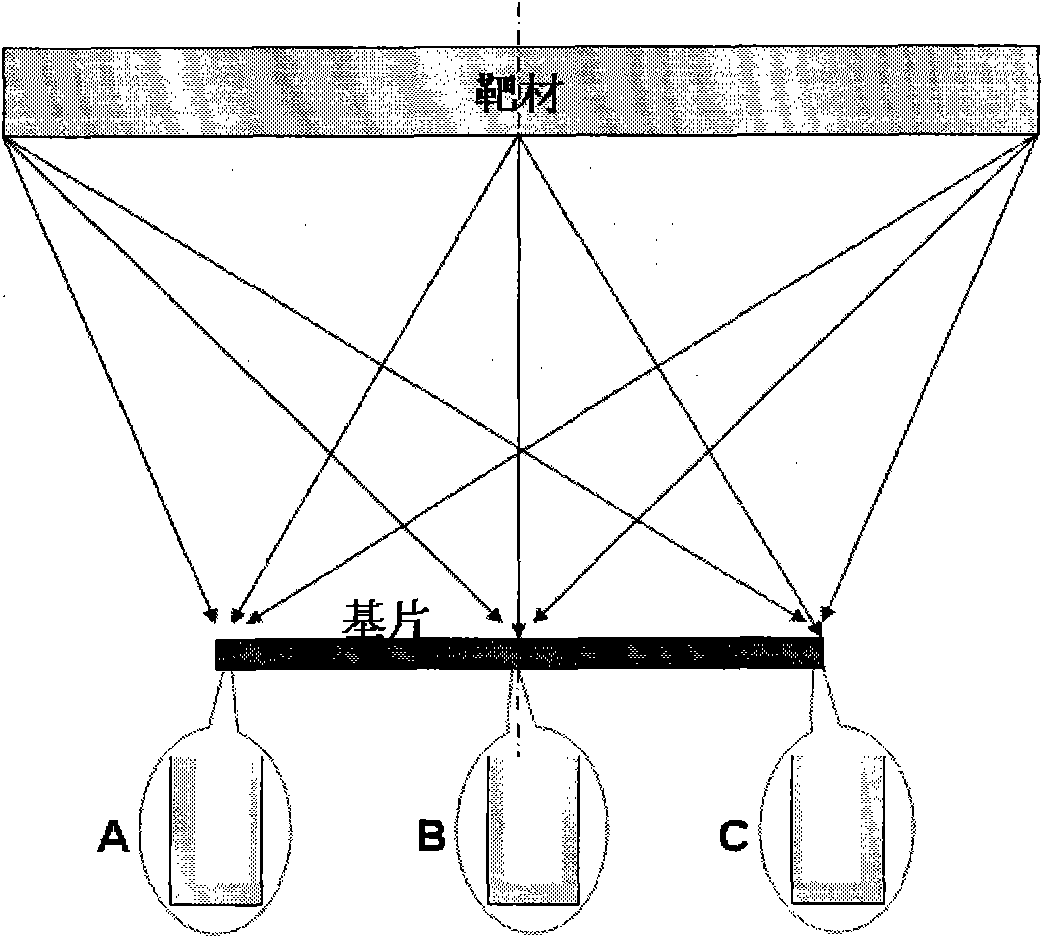

[0039] The magnetron provided by the present invention is used to form a uniformly distributed magnetic field on the surface of a target in a plasma sputtering process, thereby increasing the ionization rate of metal atoms. The magnetron includes: a central magnetron subregion, which has a central magnet group corresponding to the magnetic field applied to the central region of the target; an edge magnetron subregion, which is arranged around the central magnetron subregion, and has a magnetic field corresponding to the target edge region. The edge magnet group of magnetic field; Drive mechanism, it comprises the center drive mechanism that is connected with cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com