Self-propelled transmission line outgoing overhaul flying car

A transmission line, self-propelled technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of disconnection, high psychological pressure of personnel, and long outgoing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

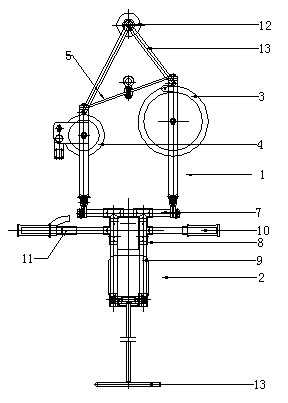

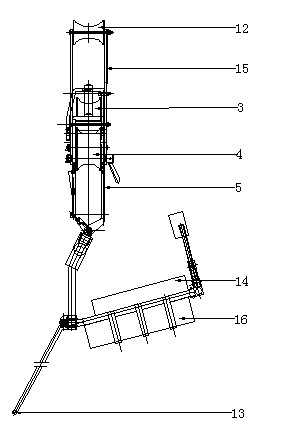

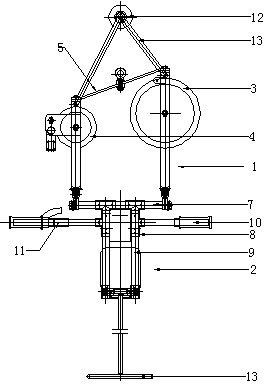

[0009] As shown in the figure, the self-propelled power transmission line overhauling flying car of the present invention includes a running mechanism 1 and a car body mechanism 2. The running mechanism 1 includes a front drive wheel 3 with a wire clamping groove that can be suspended on the transmission line and a rear slave. The driving wheel 4, the front driving wheel has a built-in hub motor that can drive the front driving wheel, the front driving wheel 3 and the rear driven wheel 4 are installed on the wheel frame 5, and the bottom of the wheel frame 5 is provided with a support frame 7; The casing 8 is suspended on the frame 9 on the support frame, the upper end of the frame 9 is provided with a handlebar 10, the inner side of the handlebar 10 is provided with a steering switch 11, and the frame 9 is provided with a pedal 13, a seat cushion 14 and a battery assembly 16; The main running mechanism 1 is provided with an upper wheel 12, and the upper wheel 12 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com